Structural design method of TC11 alloy blisk precision forging

A technology of integral blisks and precision forgings, applied in metal processing equipment and other directions, can solve the problems of high processing cost, low material utilization rate, destruction of forging streamlines, etc., and achieve the effect of ensuring comprehensive mechanical properties and reducing machining hours.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

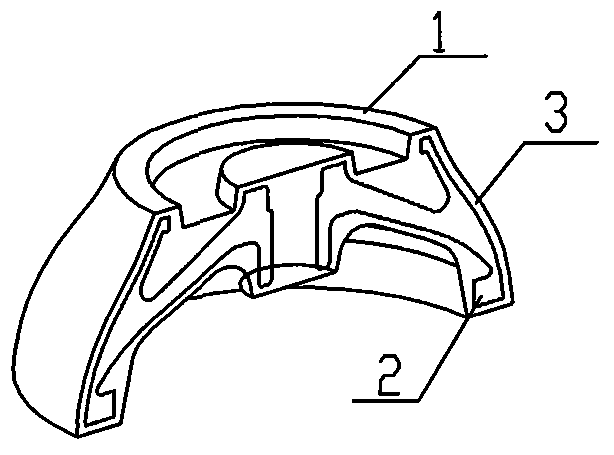

[0013] 1. First, the center wheel part adopts the design of adding 3mm machining allowance along the entire outer contour of the wheel, such as figure 2 Shown

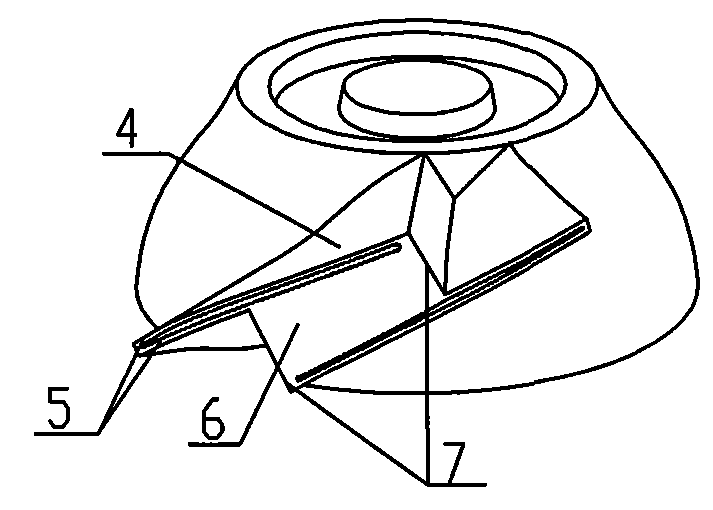

[0014] 2. The single blade of the integral blisk is designed with a machining allowance of 3mm enveloping in the normal direction of the finished blade shape, and the overlapping part between the blade and the blade fills the process residual material, and the release angle is designed to be 8 degrees. Forgings of a single blade in a blisk, such as image 3 Shown.

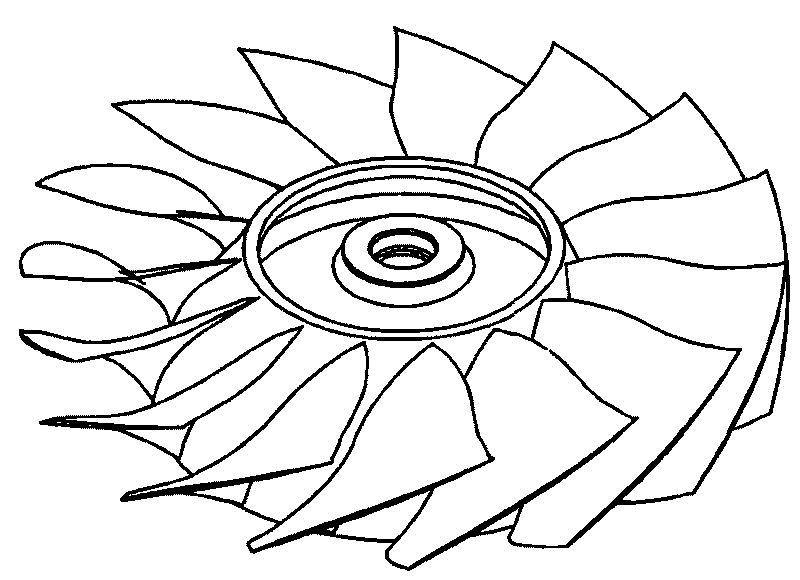

[0015] 3. Array a single blade forging around the center of rotation to form the finished blade shape, and round the edges to obtain a precision forging of the integral blisk, such as Figure 4 Shown.

Embodiment 2

[0017] 1. First, the central roulette part adopts the design of adding a machining allowance of 5mm along the entire outer contour of the roulette, such as figure 2 Shown

[0018] 2. The single blade of the integral blisk is designed with a machining allowance of 3mm enveloping along the normal direction of the finished blade shape, and the overlapping part between the blade and the blade fills the process residual material, and the design of the release angle of 7 degrees is added. Forgings of a single blade in a blisk;

[0019] 3. Array a single blade forging around the center of rotation to form the finished blade shape, and round the edges to obtain a precision forging of the integral blisk, such as Figure 4 Shown.

Embodiment 3

[0021] 1. First of all, the central wheel part adopts the design of adding 4mm machining allowance along the entire outer contour of the wheel, such as figure 2 Shown

[0022] 2. The single blade of the integral blisk is designed with a machining allowance of 3mm enveloping in the normal direction of the finished blade shape, and the overlapped part between the blade and the blade fills the process residual material, and the release mold angle is designed to be 9 degrees. Forgings of a single blade in a blisk, such as image 3 Shown.

[0023] 3. Array a single blade forging around the center of rotation to form the finished blade, and round the edges to obtain a precision forging of the integral blisk, such as Figure 4 Shown.

[0024] The drawings described in the above embodiments, figure 2 1 is the design surface of the blisk center roulette forging, 2 is the finished surface of the blisk center roulette, and 3 is the machining allowance of the center roulette of the blisk; im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com