Infrared oven and GC-MS based method and infrared oven and GC-MS based device for on-line analysis of simulated combustion of cigarettes

An analysis method and infrared furnace technology, applied in the field of on-line analysis, can solve the problem of inability to use a large sample volume and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

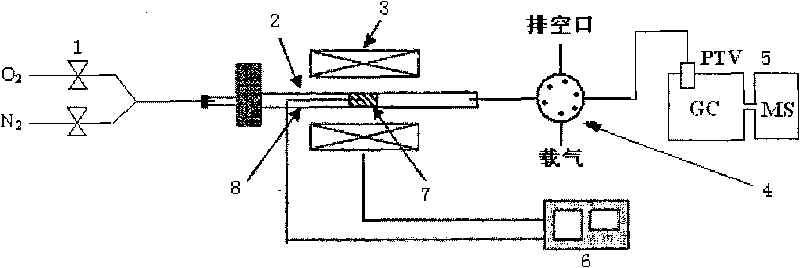

Method used

Image

Examples

Embodiment 1

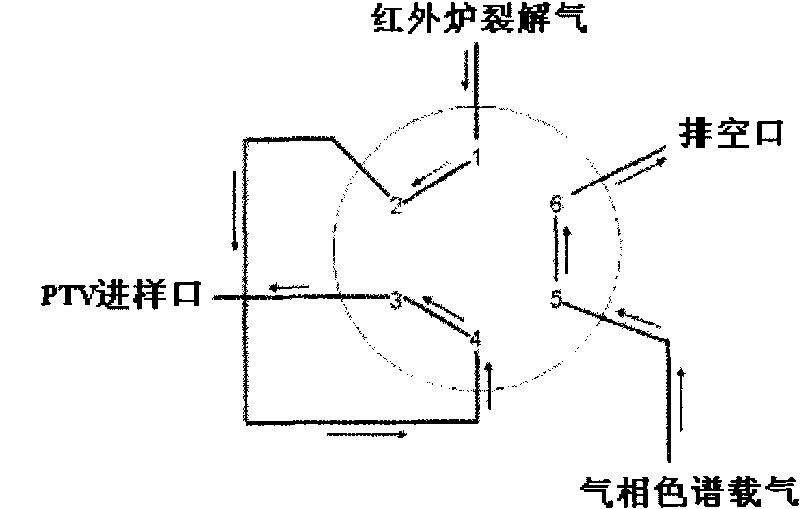

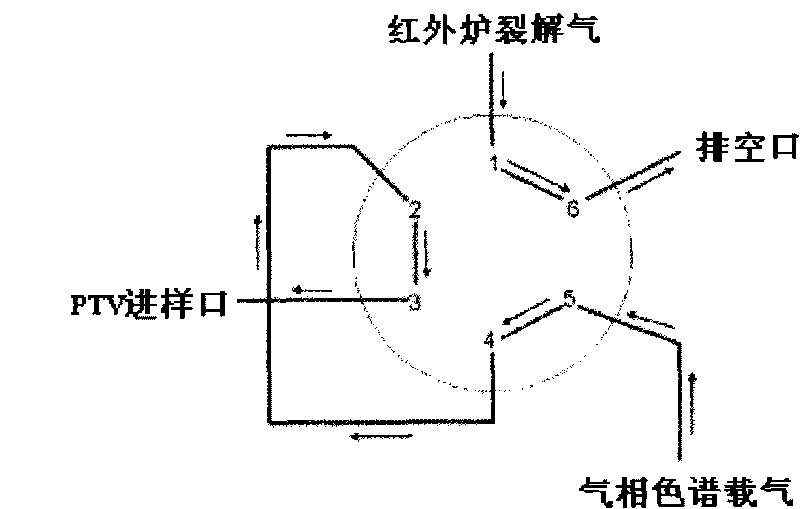

[0024] Weigh a certain amount (0.1 to 2 grams) of shredded cigarette tobacco sample, put it into the quartz tube of the focusing infrared furnace, set the sample heating program of the temperature program controller (room temperature to 1000 ° C), adjust the flow rate of the carrier gas (nitrogen 0 ~ 500mL / min, oxygen 0~500mL / min), start to heat up; when the set sampling stage is reached, change the six-way valve to the sampling state, after the sampling is completed, change the six-way valve to the sampling state; Nitrogen cooling down to -100°C to -20°C; during sample injection, the temperature of the PTV inlet can be set to a temperature rise program to allow the sample to enter the GC / MS for analysis.

[0025] GC / MS measurement conditions:

[0026] Injection port temperature: 280°C; ionization method: EI; ion source temperature: 230°C; transfer line temperature: 280°C; split ratio: 10:1~100:1; carrier gas: helium, constant flow rate 0.8~1.5mL / min; chromatographic column...

Embodiment 2

[0029] Weigh 0.5g of cigarette shredded tobacco sample, put it into the quartz tube of the focusing infrared furnace, set the sample heating program of the temperature programming controller: the initial temperature is 200°C, stay for 5 minutes, raise the temperature to 800°C at 10°C / s, and adjust the flow rate of the carrier gas (nitrogen 200mL / min, oxygen 50mL / min), start to heat up. When the temperature in the infrared furnace reaches 300 degrees, change the six-way valve to the sampling state, and when it reaches 400 degrees, change the six-way valve to the sampling state; the PTV sample inlet should be cooled to -60°C with liquid nitrogen in the sampling state; , the temperature of the PTV injection port was raised to 280 degrees at 10 °C / min, and the sample entered the GC / MS for analysis.

[0030] GC / MS measurement conditions:

[0031] Inlet temperature: 280°C; ionization mode: EI; ion source temperature: 230°C; transfer line temperature: 280°C; split ratio: 30:1; carri...

example 3

[0034] Weigh 2 grams of cigarette shredded tobacco sample, put it into the quartz tube (quartz boat) of the focusing infrared furnace, adjust the carrier gas flow rate (nitrogen 500mL / min, oxygen 50mL / min), set the sample heating program of the temperature program controller: initial temperature 100°C, stay for 5 minutes, raise the temperature to 1000°C at 50°C / sec, and start to heat up. When the temperature in the infrared furnace reaches 700 degrees, change the six-way valve to the sampling state, and change the six-way valve to the sampling state when it reaches 900 degrees. The PTV inlet was cooled to -150°C with liquid nitrogen in the sampling state. During sample injection, the temperature of the PTV injection port is raised to 280°C at 720°C / min, and the sample enters the GC / MS for analysis.

[0035] GC / MS measurement conditions:

[0036]Inlet temperature: 280°C; ionization mode: EI; ion source temperature: 230°C; transfer line temperature: 280°C; split ratio: 200:1; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com