Active equalization method for lithium ion battery pack in charging state

A lithium battery pack and charging equalization technology, which is applied in secondary battery charging/discharging, battery circuit devices, electric vehicles, etc., can solve the problems of increasing system complexity, reducing power transfer efficiency, and low transfer efficiency, achieving high efficiency , large depth, high power effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

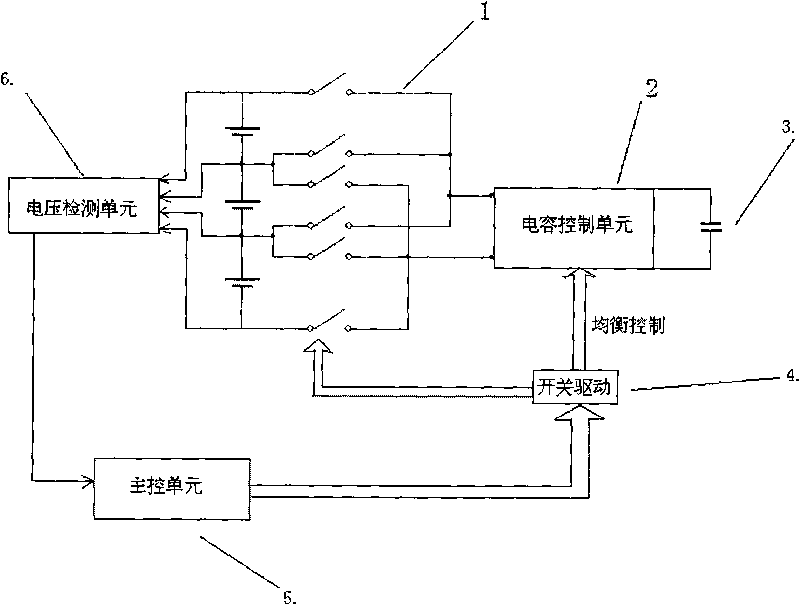

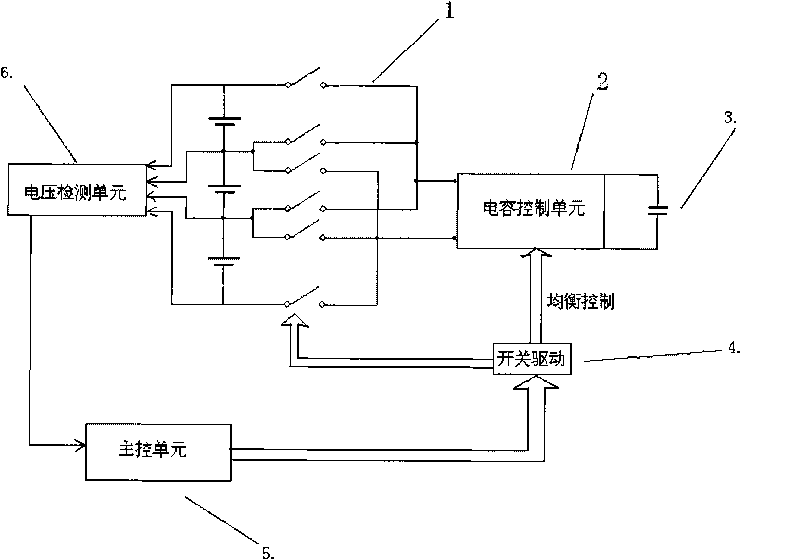

[0035] Embodiment 1: Equalization during charging of 6-series lithium battery pack

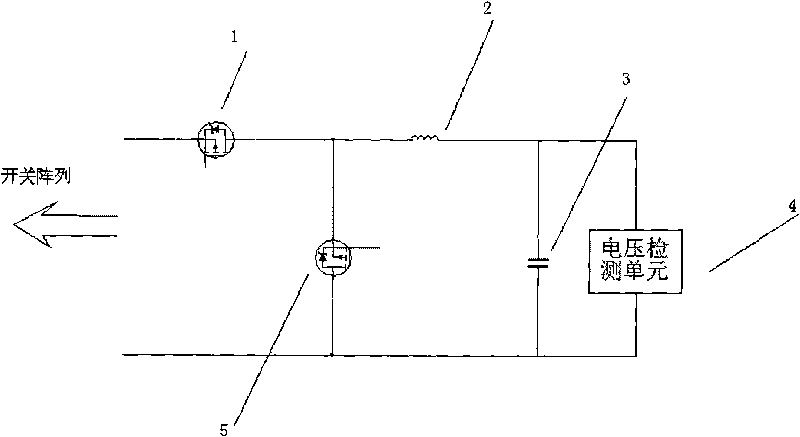

[0036] Components and parameter settings: 1) The discharge current of the capacitor is 2A, the end-of-discharge voltage is 2V, and the end-of-charge voltage is the value of the battery voltage minus 0.3. Calculated according to formula (1), when the battery voltage is 3.8V, the capacitor charging termination voltage is 3.5V, at this time the capacitor charging time is 7.2s, and the average charging current is 4.1A. 2) For the farad capacitor, choose two 20F series farad capacitor modules, and the withstand voltage is about 5.4V. 3) Inductor According to Formula 4 and Formula 5, select an inductor with an inductance of 330μH and a current above 4.5A that will not saturate. 4) Boost control frequency is set to 2kHz. 5) The capacitor charging control MOS tube and the Boost control MOS tube are P-type MOS tubes, the model is IRML6401.

[0037] The capacitor capacity is 8Ah, the charging cut-off...

Embodiment approach 2

[0039] Embodiment 2: Equalization during small current discharge

[0040] Components and parameter settings: 1) The discharge current of the capacitor is 2A, the end-of-discharge voltage is 2V, and the end-of-charge voltage is the value of the battery voltage minus 0.3. Calculated according to formula (1), when the battery voltage is 3.8V, the capacitor charging termination voltage is 3.5V, at this time the capacitor charging time is 7.2s, and the average charging current is 4.1A. 2) For the farad capacitor, choose two 20F series farad capacitor modules, and the withstand voltage is about 5.4V. 3) Inductor According to Formula 4 and Formula 5, select an inductor with an inductance of 330μH and a current above 4.5A that will not saturate. 4) Boost control frequency is set to 2kHz. 5) The capacitor charging control MOS tube and the Boost control MOS tube are P-type MOS tubes, the model is IRML6401.

[0041] The capacitor capacity is 8Ah, and the initial voltage of the battery...

Embodiment approach 3

[0043] Embodiment 3: Equilibrium during standing

[0044] Components and parameter settings: 1) The discharge current of the capacitor is 2A, the end-of-discharge voltage is 2V, and the end-of-charge voltage is the value of the battery voltage minus 0.3. Calculated according to formula (1), when the battery voltage is 3.8V, the capacitor charging termination voltage is 3.5V, at this time the capacitor charging time is 7.2s, and the average charging current is 4.1A. 2) For the farad capacitor, choose two 20F series farad capacitor modules, and the withstand voltage is about 5.4V. 3) Inductor According to Formula 4 and Formula 5, select an inductor with an inductance of 330μH and a current above 4.5A that will not saturate. 4) Boost control frequency is set to 2kHz. 5) The capacitor charging control MOS tube and the Boost control MOS tube are P-type MOS tubes, the model is IRML6401.

[0045] The capacitor capacity is 8Ah, and the initial voltage of the battery pack is 21.892V...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com