Cutting rotor

A technology for cutting rotors and rotors, which is applied in metal processing, grain processing, etc., can solve the problems of poor cutting effect and achieve good cutting effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

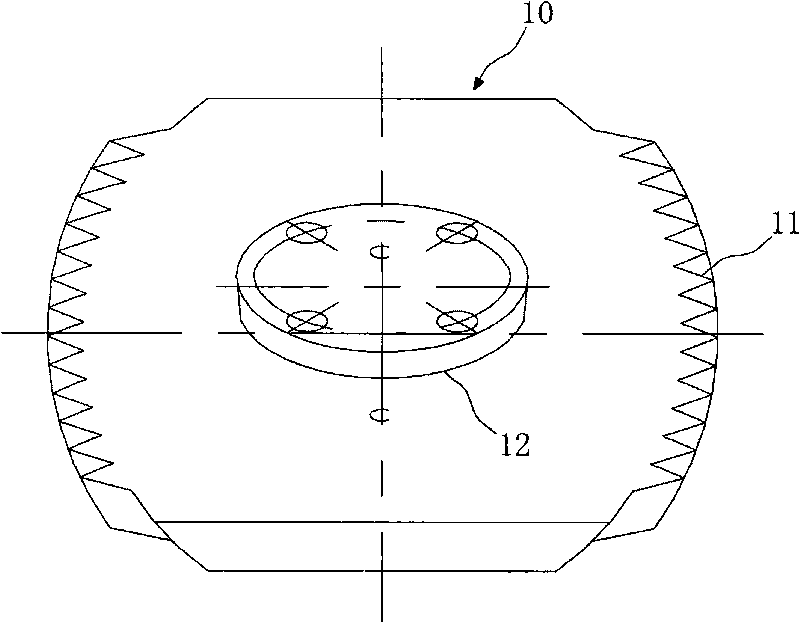

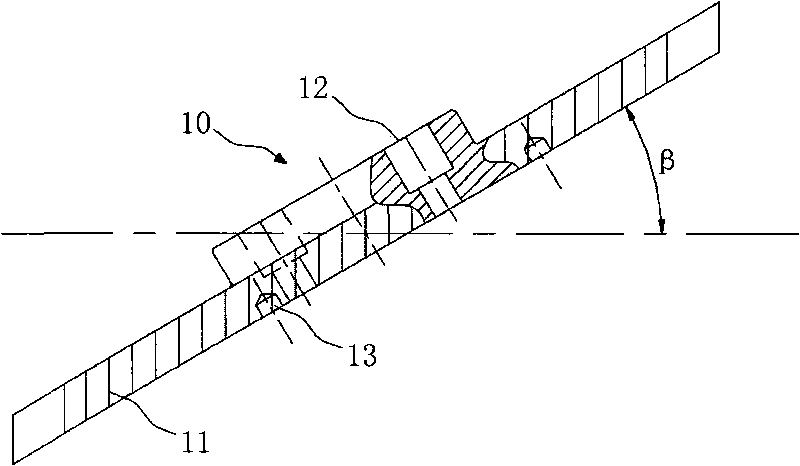

[0010] Such as figure 1 , 2 As shown in , 4, a cutting rotor, the rotor 10 is plate-shaped, the plate surface of the rotor 10 forms an angle β with the horizontal plane, and the side edge of the rotor 10 rotating around the horizontal line passing through the rotor plate surface is provided with teeth 11. The tooth tops of the teeth 11 are located on the same rotary surface, and the extension direction of the tooth tops of the teeth 11 is the same as the tangential direction of the rotary surface.

[0011] Further, the horizontal line around which the rotor 10 rotates is the horizontal projection line formed by the projection of the center line of symmetry of the rotor 10 on the horizontal plane. This rotation mode makes the rotation of the rotor 10 more stable and can obtain better cutting Effect.

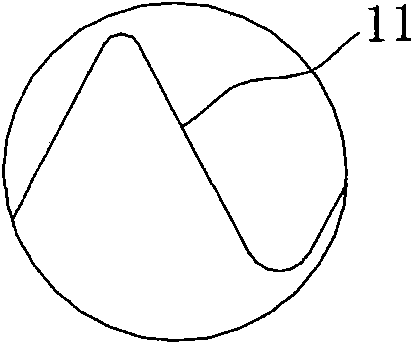

[0012] Such as image 3 As shown, the tooth top cross-section of the tooth 11 is arc-shaped, and this design of the tooth 11 is conducive to reducing the stress concentration p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com