Pulse combustion temperature control method of heat treating furnace

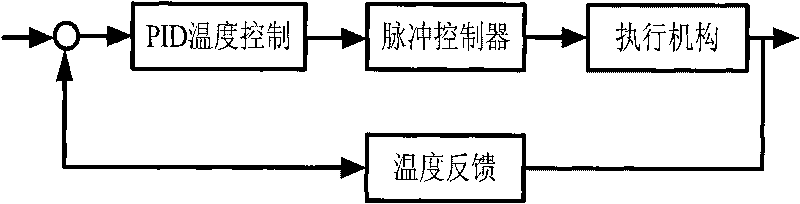

A temperature control method and heat treatment furnace technology, applied in the field of heat treatment, can solve the problems of PID temperature adjustment difficulties, loss of temperature control accuracy, high temperature, etc., and achieve good dynamic response, fast dynamic response, and short adjustment time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0081] There is a continuous annealing furnace, which is divided into 12 sections and 24 zones for temperature control, and each section has two temperature control zones up and down. The first 8 sections are heating sections, and the last 4 sections are soaking sections. When no billet enters, the first eight sections adopt fuzzy PID pulse combustion control, and the last four sections adopt conventional PID pulse combustion control. Assuming that a certain steel type determines the set temperature according to the production process, the 1-2 stage is 820°C, the 3-4 stage is 850°C, the 5th stage is 870°C, the 6th stage is 890°C, the 7-12 stage is 900°C, the target furnace temperature is 900°C, no Fuzzy or conventional PID pulse regulation during billet can be used for precise temperature control.

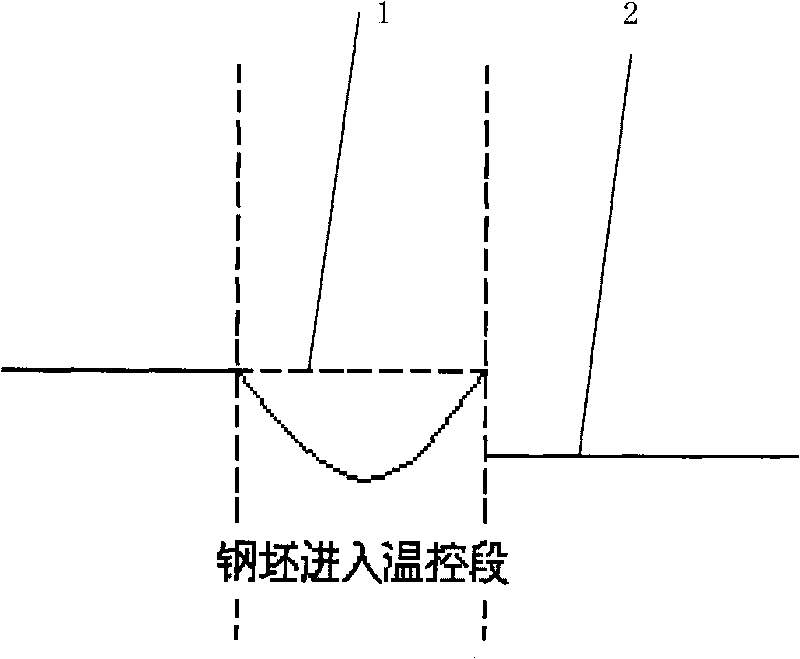

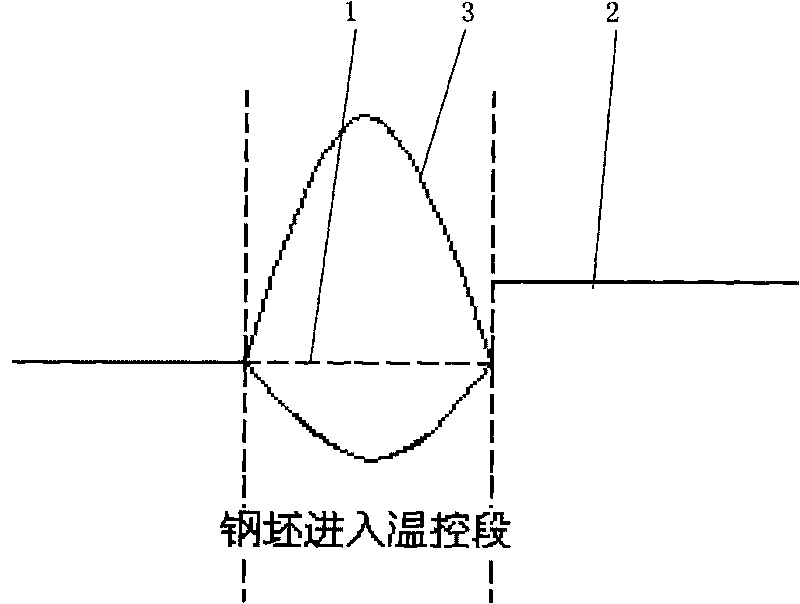

[0082] First, formulate the control rules for heating according to the volume of the billet and the characteristics of the steel type. Take the first section and the first distric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com