A control method for implementing NAC process of marine plate by using quenching machine device

A control method and marine board technology, applied in the field of heat treatment, can solve problems such as connection, limited use of quenching machines, difficulty in ensuring temperature compliance, etc., and achieve the effects of strong pertinence, easy realization, and performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

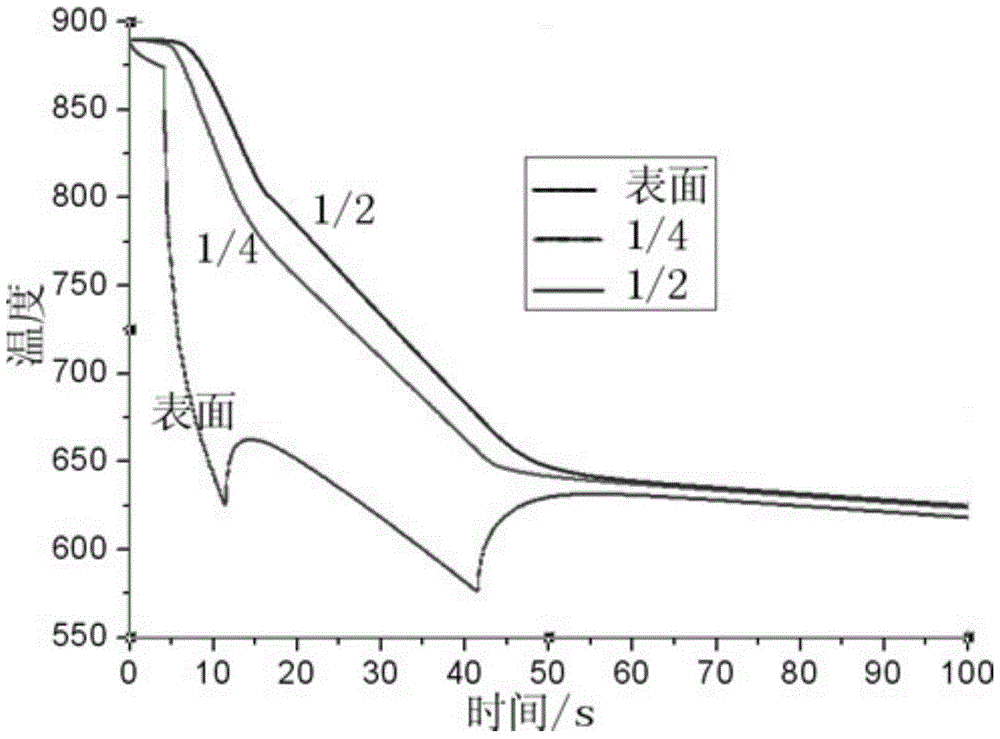

Embodiment 1

[0025] The steel type is 20mm D36N; the shape of the incoming material is 5mm / m; the total heating time is 30min, and the soaking time is 20min; the soaking temperature is 890°C, the furnace temperature is 887°C, and the cooling temperature is 877°C; The cooling water temperature is controlled at 25°C. The opening mode of the quenching machine: the aerosol section is closed; the water volume at the high pressure end is 200m 3 / h, the water ratio is set to 1.20; the low pressure end is 120 m 3 / h; the water ratio is set to 1.20; the measurement time of the redness temperature point is 10s after exiting the quenching machine, the redness temperature is 630°C, and the cooling rate is 4.0°C / s.

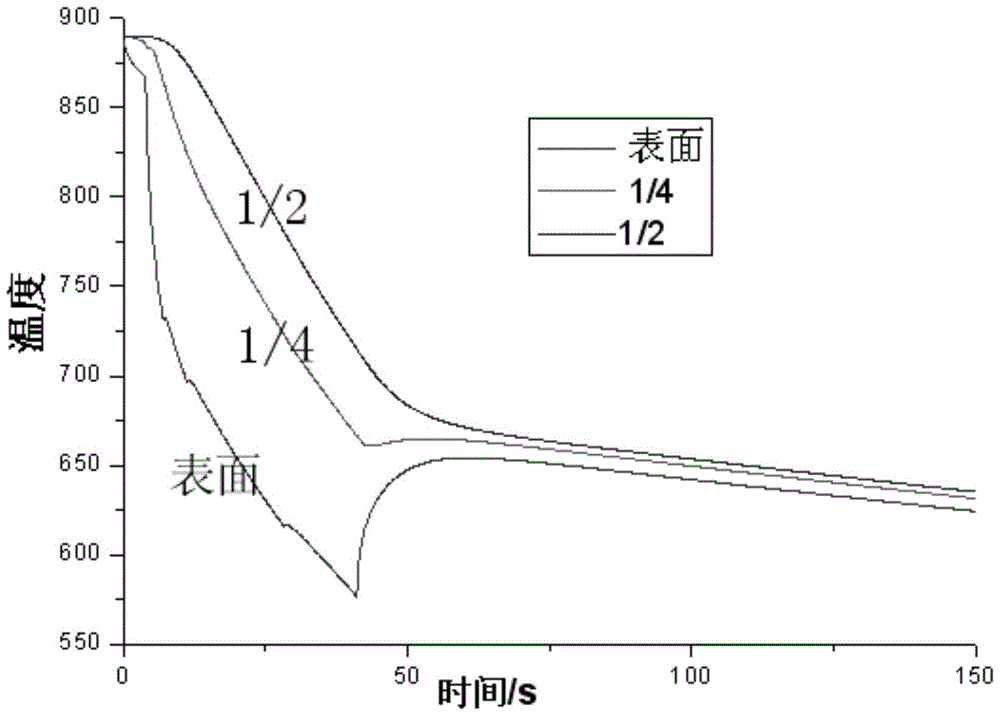

Embodiment 2

[0027] The steel type is 45mm D36N; the incoming plate shape is 4mm / m; the total heating time is 65min, and the soaking time is 30min; the soaking temperature is 891°C, the furnace temperature is 889°C, and the cooling temperature is 882°C; The cooling water temperature is controlled at 25°C. The opening mode of the quenching machine: the aerosol section is closed; the water volume at the high pressure end is 260m 3 / h, the water ratio is set to 1.30; the low pressure end is 150 m 3 / h; the water ratio is set to 1.30; the measurement time of the redness temperature point is 12s after exiting the quenching machine, the redness temperature is 635°C, and the cooling rate is 5.2°C / s.

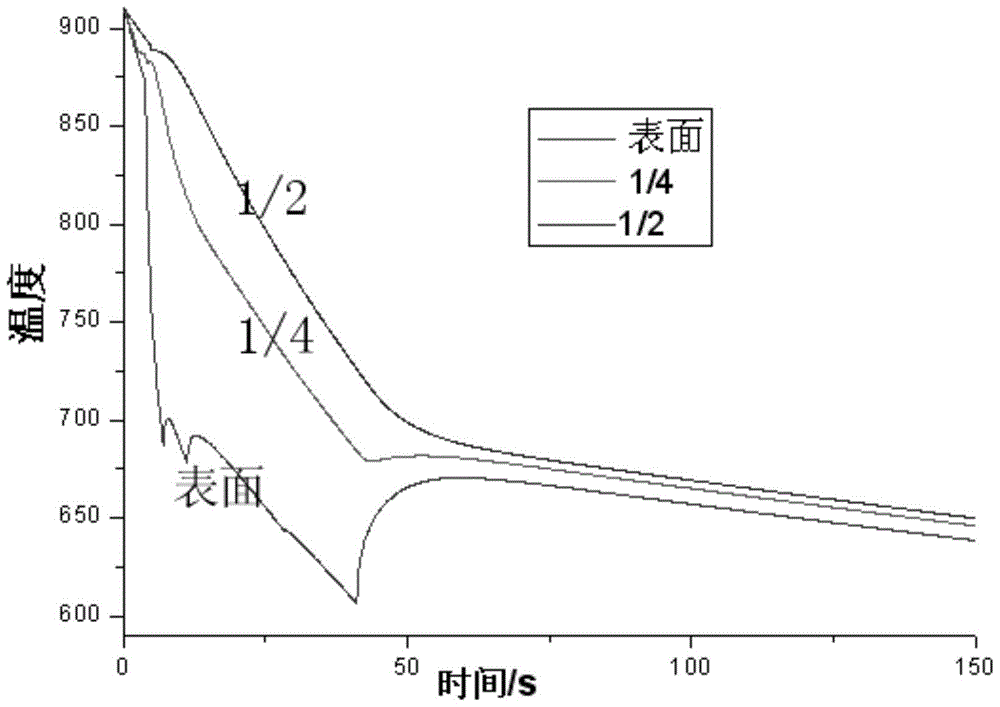

Embodiment 3

[0029] The steel type is 60mm E36N; the shape of the incoming material is 3mm / m; the total heating time is 125min, and the soaking time is 40min; the soaking temperature is 908°C, the furnace temperature is 906°C, and the cooling temperature is 902°C; The cooling water temperature is controlled at 25°C. The opening mode of the quenching machine: the aerosol section is closed; the water volume at the high pressure end is 350m 3 / h, the water ratio is set to 1.40; the low pressure end is 180 m 3 / h; the water ratio is set to 1.40; the measurement time of the temperature point of turning red is 18s after exiting the quenching machine, the temperature of turning red is 660°C, and the cooling rate is 6.5°C / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com