Air way of engine cylinder head and device for detecting and simulating performance of combustion chamber

A simulation device and combustion chamber technology, which is applied in the direction of engine testing, measuring devices, machine/structural component testing, etc., can solve the problems of time-consuming resources and heavy workload, and achieve time saving, short production cycle, and good roughness The effect of degree and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

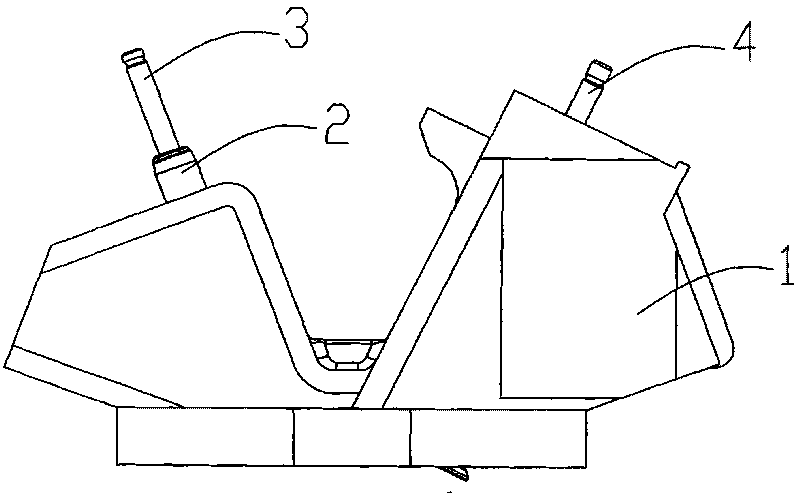

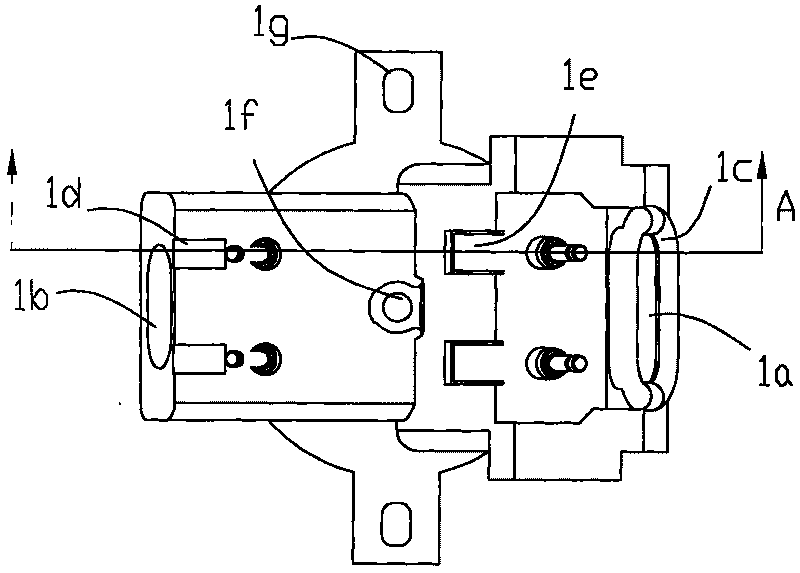

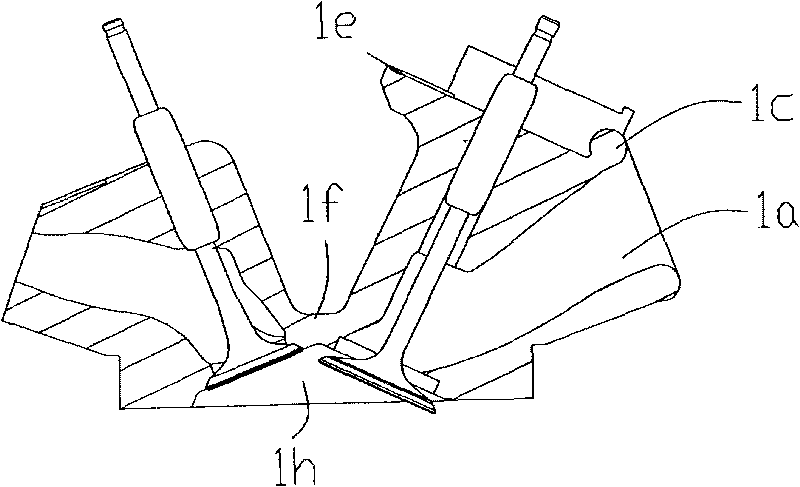

[0015] Such as figure 1 As shown, the simulation device includes a body 1, a valve guide 2, an exhaust valve 3, an intake valve 4, and the like. The device is made of synthetic resin, which simulates the structure of the cylinder head, and the left and right parts of the body 1 are provided with an intake port 1a, an exhaust port 1b, and inclined holes for installing intake and exhaust valve guides, and a combustion chamber is provided at the bottom. The valve guide 2 is pressed into the installation inclined holes of the intake and exhaust valve guides on both sides of the body 1 with interference, while the exhaust valve 3 and the intake valve 4 are installed in the valve guide 2, and can be inclined along the inside of the valve guide 2. The direction of the hole is moved to simulate the movement state of the valve in the intake and exhaust. The intake port 1a, the exhaust port 1b and the combustion chamber 1h are the shapes to be detected, which are made according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com