Ultraviolet cured vacuum spraying colored paint

A vacuum spraying and ultraviolet light technology, applied in coatings, polyester coatings, epoxy resin coatings, etc., can solve problems such as lack of covering power and inability to adapt to the continuous recycling of vacuum spraying equipment, achieving fast curing speed, production High efficiency and the effect of overcoming large pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

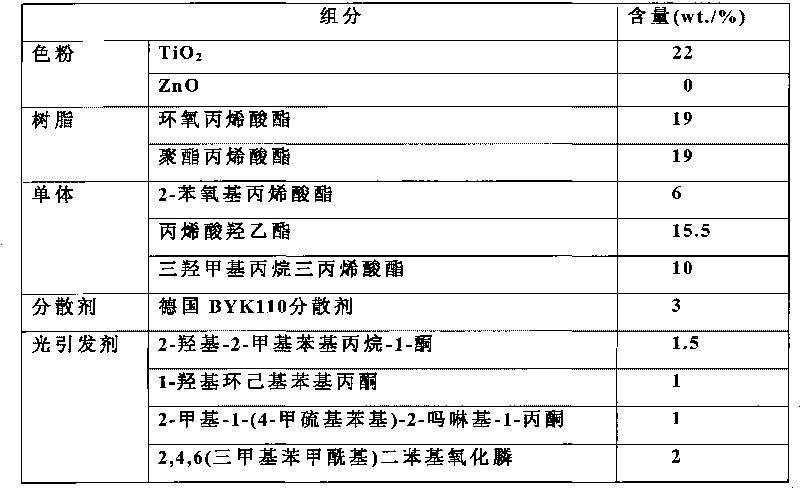

[0014] According to the ultraviolet light curing vacuum spraying white paint of this embodiment, the composition is shown in Table 1 as follows.

[0015] Table 1

[0016]

[0017] The white paint of this embodiment can be prepared by the following method: First, stir the toner, a part of the resin, a part of the monomer, and the dispersant evenly, and after grinding and dispersing with three rollers, add the remaining monomer, the remaining resin and the photoinitiator, Stir for more than 20min.

Embodiment 2

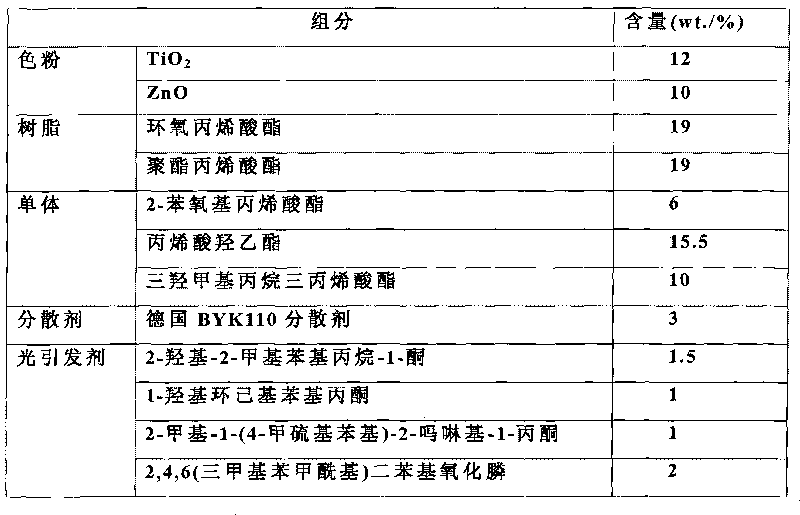

[0019] According to the ultraviolet light curing vacuum spraying white paint of this embodiment, the composition is shown in Table 2 as follows.

[0020] Table 2

[0021]

Embodiment 3

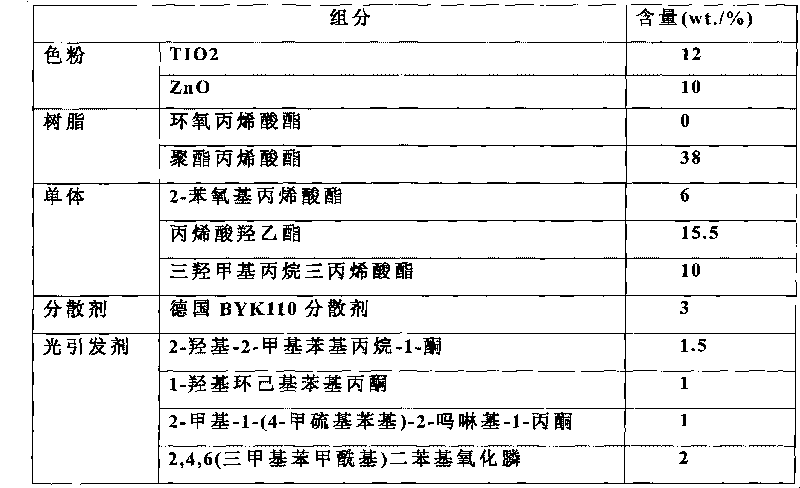

[0023] According to the ultraviolet light curing vacuum spraying white paint of this embodiment, the composition is shown in Table 3 as follows.

[0024] table 3

[0025]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap