Reinforced concrete frame abutment shallow pile plate foundation under two-driveway beam type cross connecting beam

A technology of pile-slab foundation and soil abutment, which is applied in the field of shallow pile-slab foundation of reinforced concrete frame pier under two-lane girder-type cross-link beams, can solve the problems of raw material waste and difficult work, and achieve convenient construction and lower foundation The cost and the effect of increasing the area of shallow piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

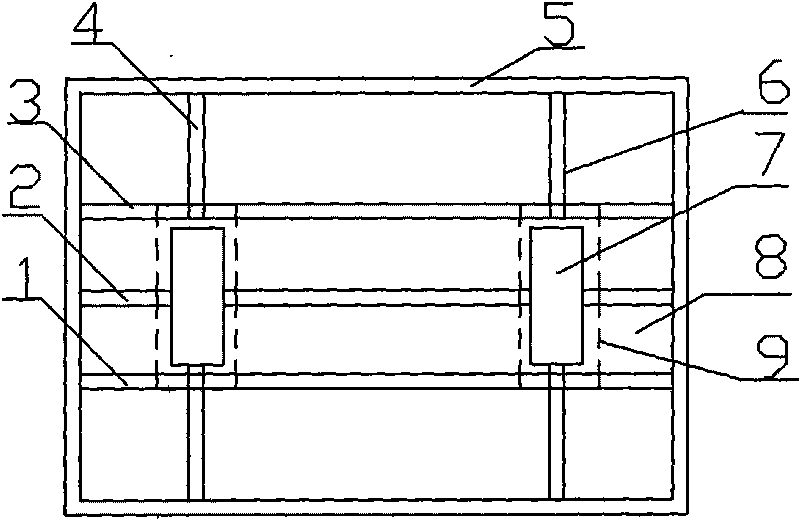

[0019] Depend on figure 1 It can be seen that the shallow pile-slab foundation of the reinforced concrete frame pier under the two-lane beam type cross-link beam is composed of a reinforced concrete slab foundation 8 and a reinforced concrete shallow pile 9 connected under the slab foundation, and the shallow pile 9 is two symmetrical Rectangular shallow piles, the frame of the slab foundation 8 is arranged crosswise by two vertical anti-cantilever beams (4, 6) and three transverse anti-cantilever beams (1, 2, 3). as one.

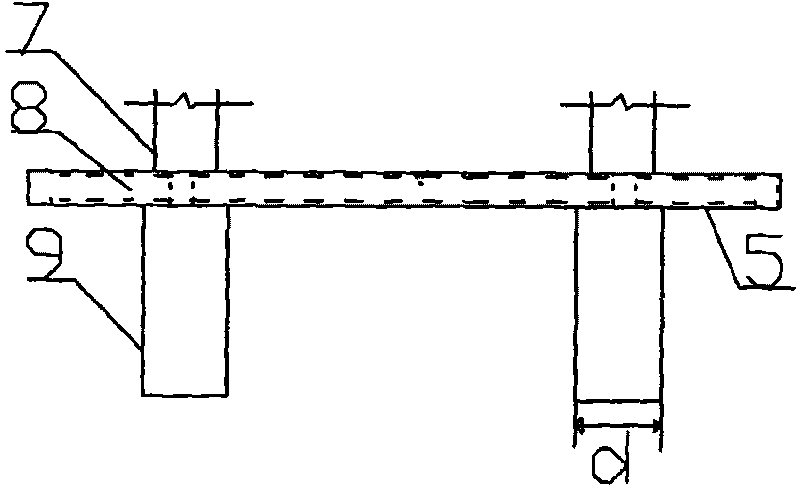

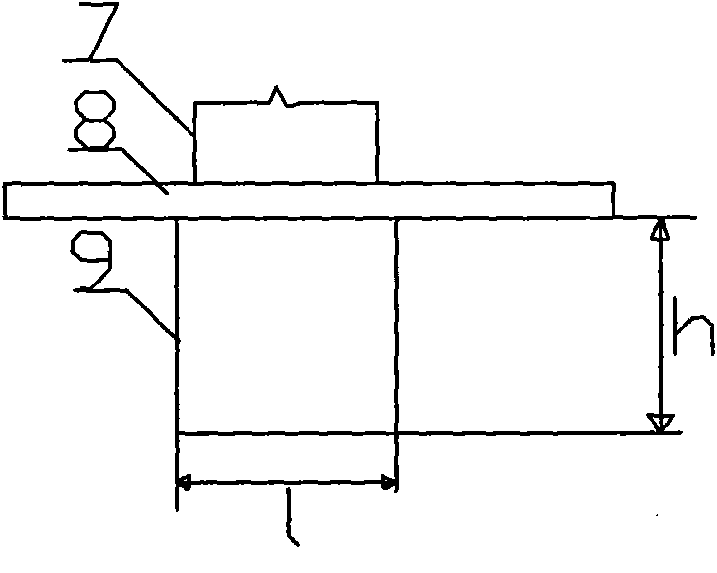

[0020] Depend on figure 2 , image 3 Can find out: described shallow pile length L=1.75 meters, wide d=1.14 meters, height h=2 meters; Shallow pile bottom area=1.75*1.14=1.995 (meter 2 ).

[0021] Depend on figure 1 , figure 2 , image 3 It can be seen that the vertical and horizontal anti-hanging beams are in the shape of a cuboid, the cross s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com