Combined type hydrogen chloride synthetic furnace of by-product high-pressure steam

A high-pressure steam and synthesis furnace technology, applied in the direction of chlorine/hydrogen chloride, etc., can solve problems such as difficult operation, high iron ion content, and harsh service conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

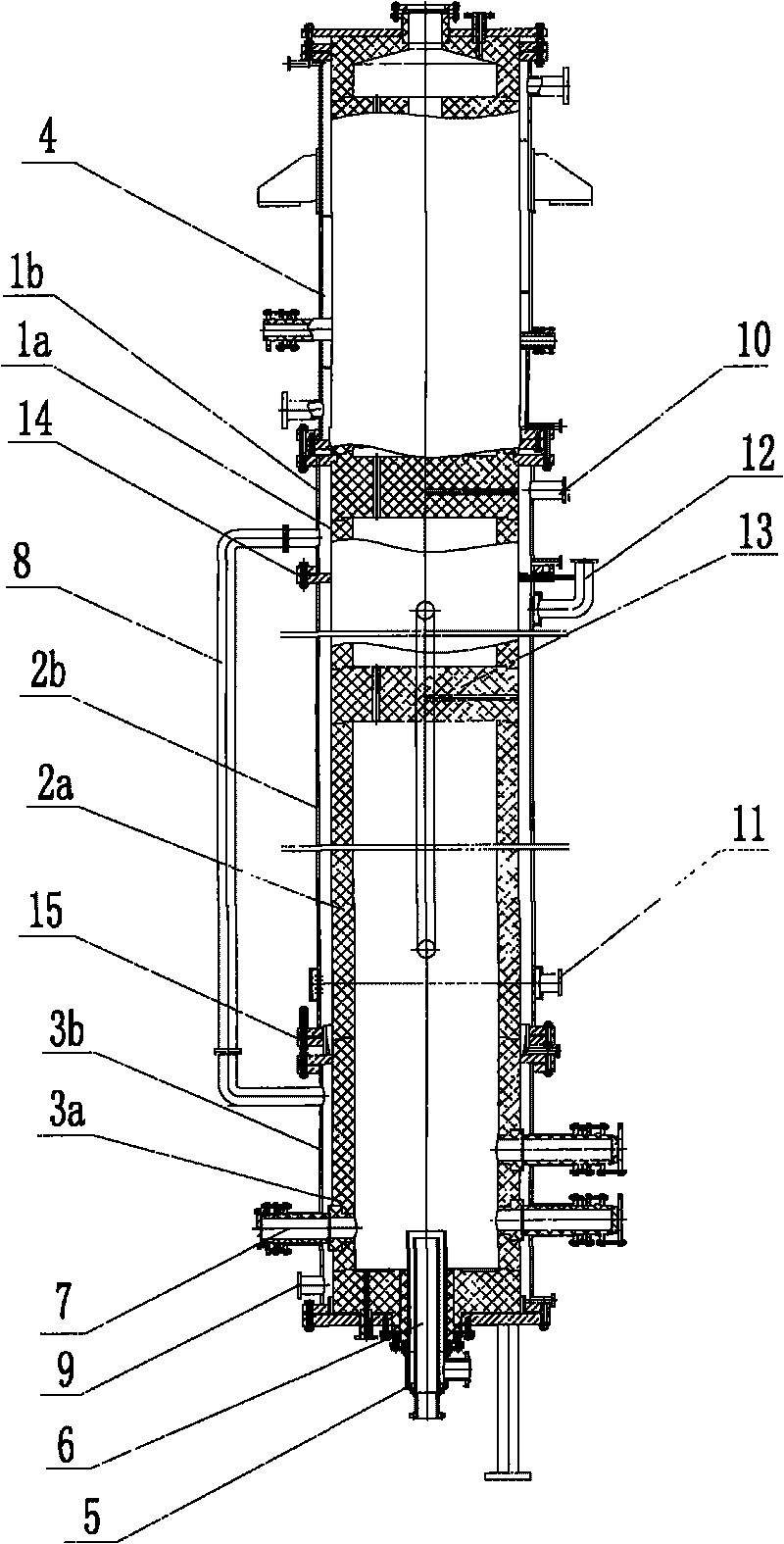

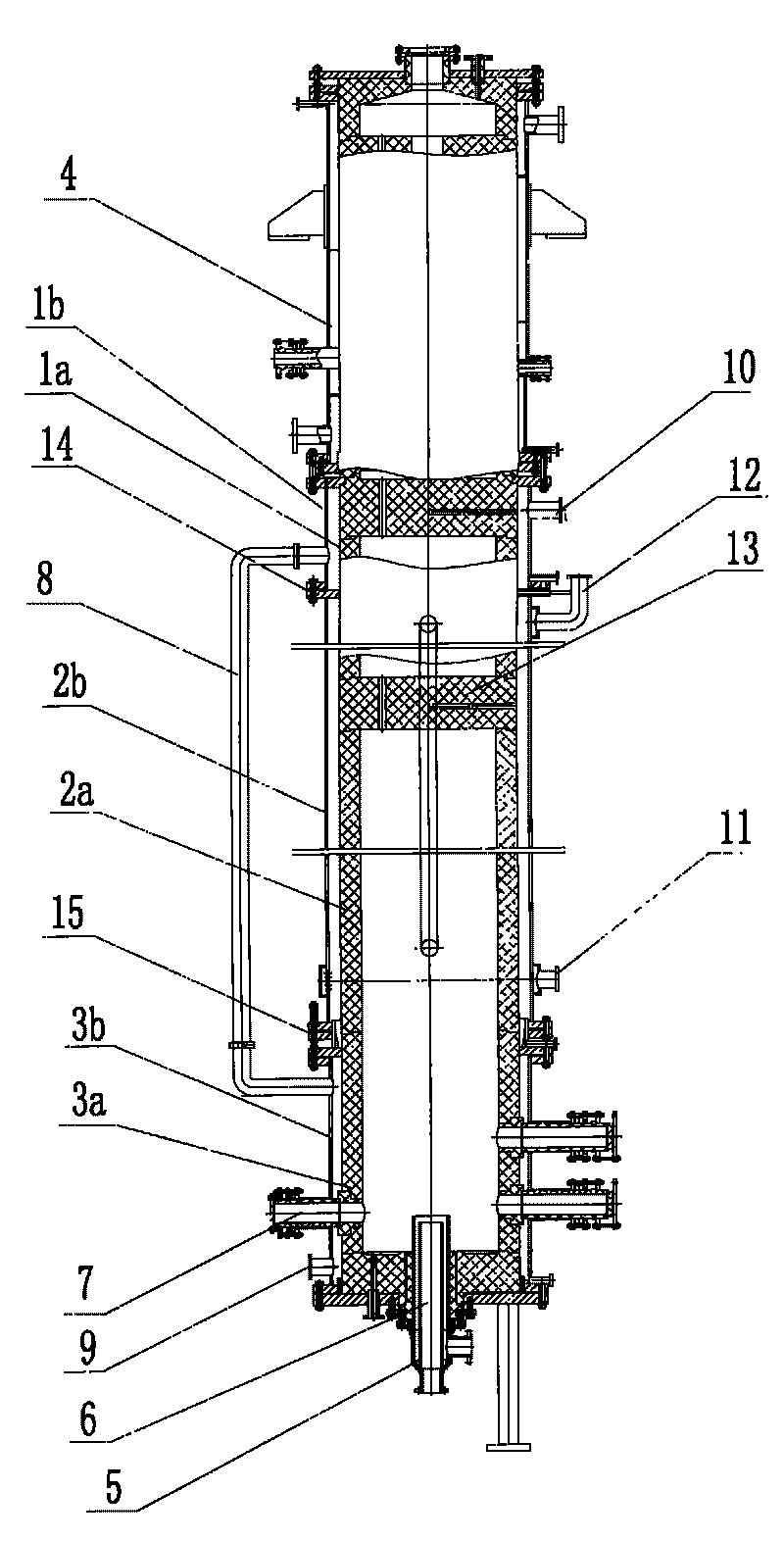

[0012] As shown in the accompanying drawings, the present invention relates to a combined hydrogen chloride synthesis furnace capable of producing high-pressure steam by-product, which includes a synthesis furnace for synthesizing hydrogen chloride gas and a cooler 4 for cooling high-temperature hydrogen chloride gas on its upper part.

[0013] The synthesis furnace is divided into upper section 1, middle section 2 and lower section 3, all of which are composed of a graphite cylinder a and a steel casing b set outside the cylinder. The internal graphite cylinders 1a, 2a, and 3a of the upper, middle, and lower sections are bonded and conducted with graphite-filled phenolic adhesive to form an inner cavity for preparing hydrogen chloride gas; the outer steel shells 1b, 2b , 3b are connected by flanges 14, 15, and the three and the graphite cylinder 1a, 2a, 3a form three mutually non-conductive interlayers.

[0014] The bottom end of the lower section 3 of the synthesis furnace i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com