Ignition device for engine

An ignition device, engine technology, applied in the direction of engine ignition, engine components, machines/engines, etc., to achieve the effect of improving efficiency and emission effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

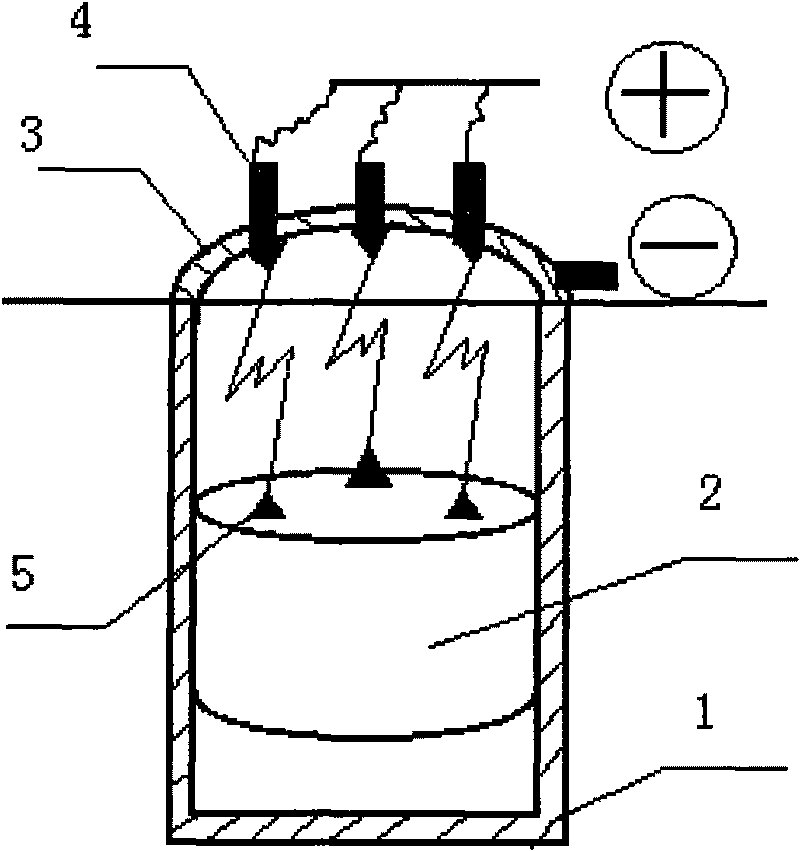

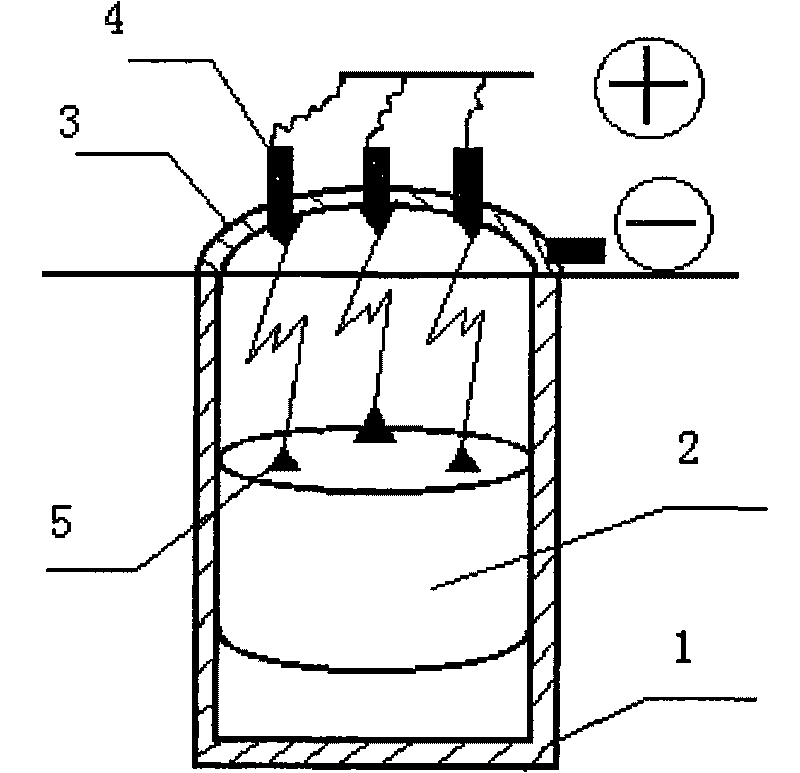

[0018] Such as figure 1 As shown, an engine ignition device of the present invention is characterized in that it includes: a cylinder, a spark plug, a piston, a cylinder head, etc., and is characterized in that the cylinder head has a needle electrode.

[0019] The piston 2 is in the cylinder 1, and the piston 2 has a needle electrode, and the cylinder head 3 has a needle electrode 4 correspondingly on the cylinder head. The electrode corresponds to the position of the electrode 5 on the piston, and the distance is the smallest when the piston moves to the top dead center. The number of needle electrodes on the cylinder head and the electrode needles on the piston can be inconsistent. It is also possible to have acicular electrodes on one side and a common metal surface on the other side.

[0020] Beneficial effect

[0021] The invention will improve the combustion efficiency of the internal combustion engine and reduce the pollutant emissions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com