Manufacture method of golden finger printed board

A manufacturing method and gold finger technology, which is applied in the reinforcement of conductive patterns, the secondary treatment of printed circuits, the formation of electrical connections of printed components, etc., can solve the problems of low efficiency, complicated process flow, and increased material costs, and reduce the cost of leads. Design, convenience of gold plating layer, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

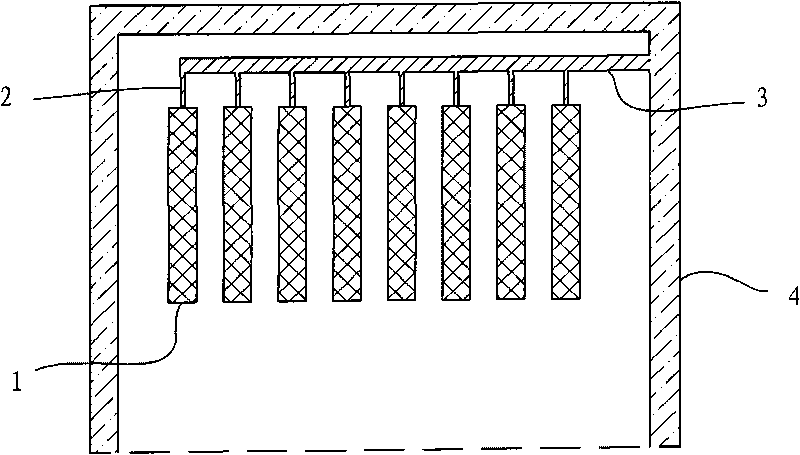

[0023] A kind of manufacturing method of golden finger printed board, it comprises the following steps:

[0024] a. Inner layer graphic production, the inner layer board can be made according to the design requirements;

[0025] b. Lamination, drilling, copper sinking, board surface electroplating;

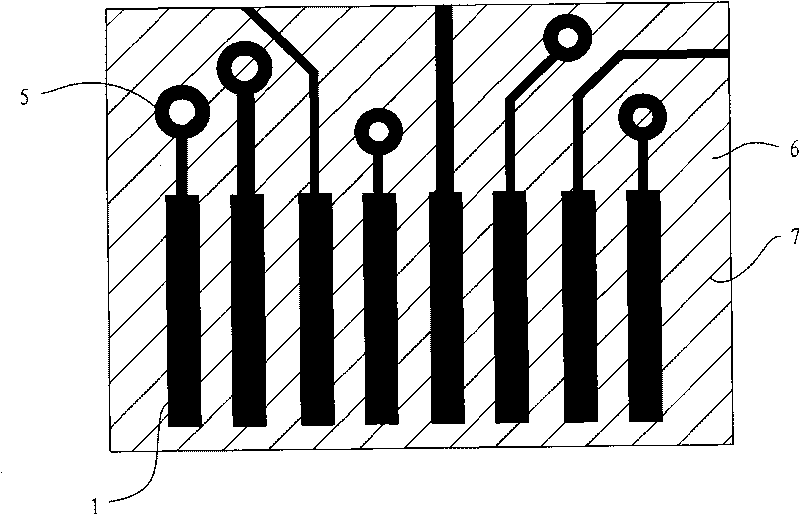

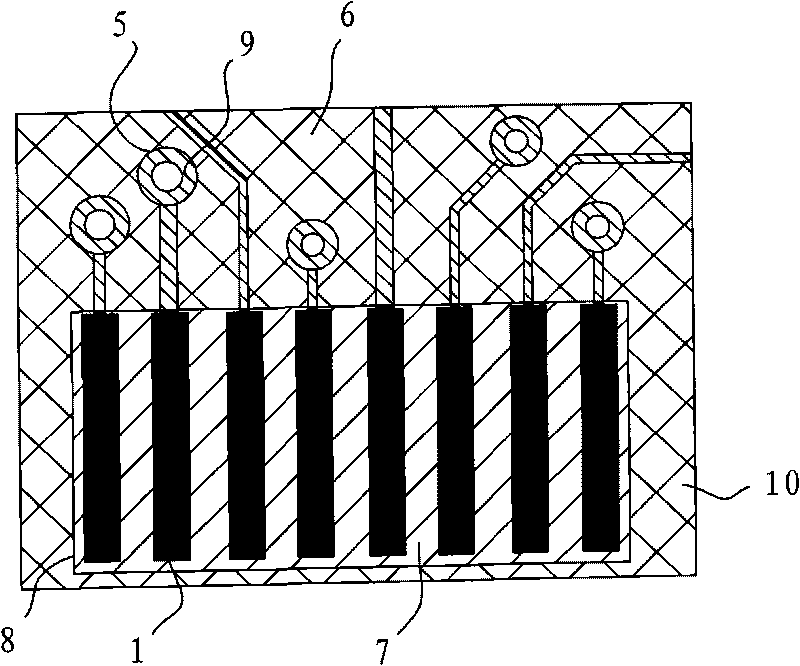

[0026] c. The first outer graphics transfer: refer to figure 2 , make the outer layer circuit graphics on the outer layer board, the graphic of the film used is the outer layer circuit graphic, and the graphic part is black, light blocking, the non-graphic part is transparent, light transmission, at a pressure of 0.2-0.6Mpa, a temperature of 90- Under the condition of 130°C, the first layer of dry film (photoresist film) is pasted on both sides of the printed board. After exposure to 5-12 levels of ultraviolet energy, it is developed with a weak alkali solution of sodium carbonate. It can be developed according to the circuit According to the type of board and the type of dry f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com