A kind of anti-seepage performance and air permeability test device and test method

A technology of air permeability and testing device, which is used in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc. There is no special method for the test of impermeability and air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

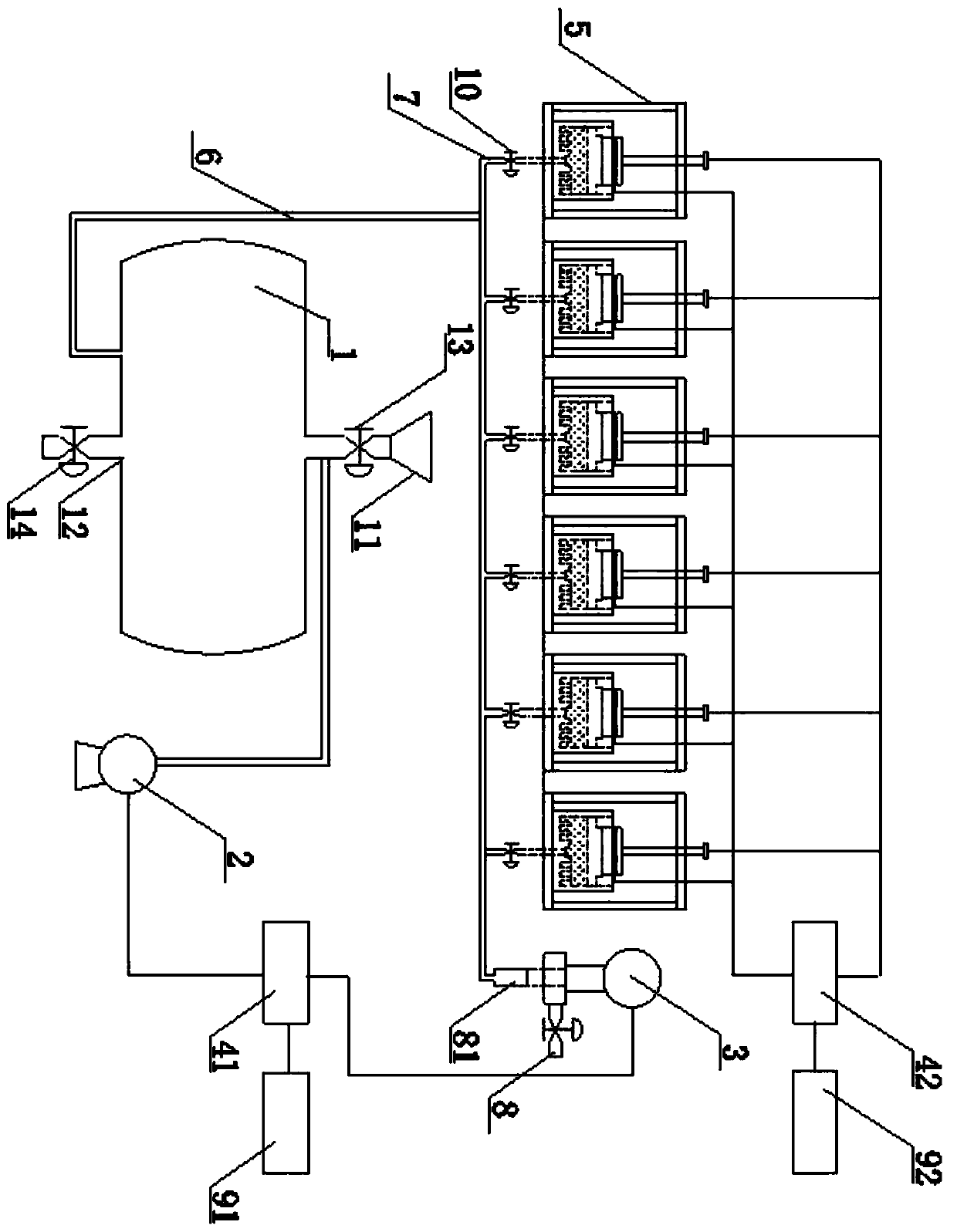

[0114] A method for testing anti-seepage performance, comprising the following steps: (the method adopts the aforementioned test device for anti-seepage performance and air permeability, wherein the material of the sample chamber is ABS plastic.)

[0115] Step 1. Water injection of the device and exhaust of the main pipe:

[0116] Close the drain valve 14, open the replenishment valve 13, replenish water in the pressure supply and control device 1 through the replenishment pipe 11, until the water accounts for 20% of the total volume of the pressure supply and control device 1, close the replenishment valve 13, set the first PLC41 to control the supply The internal pressure of the pressure control device 1 is 1kPa. The air pump 2 is used to inject air into the pressure control device 1 to increase the pressure. The pressure sensor 3 on the main pipe 6 senses the pressure and transmits the pressure signal to the first PLC41. PLC41 controls the working state of the air pump 2, a...

Embodiment 2

[0139] A method for testing anti-seepage performance, comprising the following steps: (the method adopts the aforementioned a kind of anti-seepage performance and air permeability testing device for testing, wherein the material of the sample chamber is PLA or polylactic acid.)

[0140] Step 1. Water injection of the device and exhaust of the main pipe:

[0141] Close the drain valve 14, open the replenishment valve 13, replenish water to the pressure supply and control device 1 through the replenishment pipe 11, until the water accounts for 50% of the total volume of the pressure supply and control device 1, close the replenishment valve 13, set the first PLC control supply The internal pressure of the pressure control device 1 is 5kPa. The air pump 2 is used to inject air into the pressure control device 1 to increase the pressure. The pressure sensor 3 on the main pipe 6 senses the pressure and transmits the pressure signal to the first PLC. The PLC controls the working sta...

Embodiment 3

[0170] A method for testing anti-seepage performance, comprising the following steps: (the method adopts the aforementioned test device for anti-seepage performance and gas permeability, wherein the material of the sample chamber is PVC or polyvinyl chloride.)

[0171] Step 1. Water injection of the device and exhaust of the main pipe:

[0172] Close the drain valve 14, open the replenishment valve 13, replenish water in the pressure supply and control device 1 through the replenishment pipe 11, until the water accounts for 60% of the total volume of the pressure supply and control device 1, close the replenishment valve 13, set the first PLC control supply The internal pressure of the pressure control device 1 is 8kPa. The air pump 2 is used to inject air into the pressure control device 1 to increase the pressure. The pressure sensor 3 on the main pipe 6 senses the pressure and transmits the pressure signal to the first PLC. The PLC controls the working state of the air pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com