Method for desulfurating and denitrating and recovering sulfur resource in closed cycle way

A closed cycle, desulfurization and denitrification technology, applied in desulfurization, dust removal and resource recovery technology and environmental protection, denitrification fields, can solve the problems of difficult by-product treatment, high operating costs, secondary pollution, etc., to meet resource recovery and environmental governance requirements, reduce operating costs, and save resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

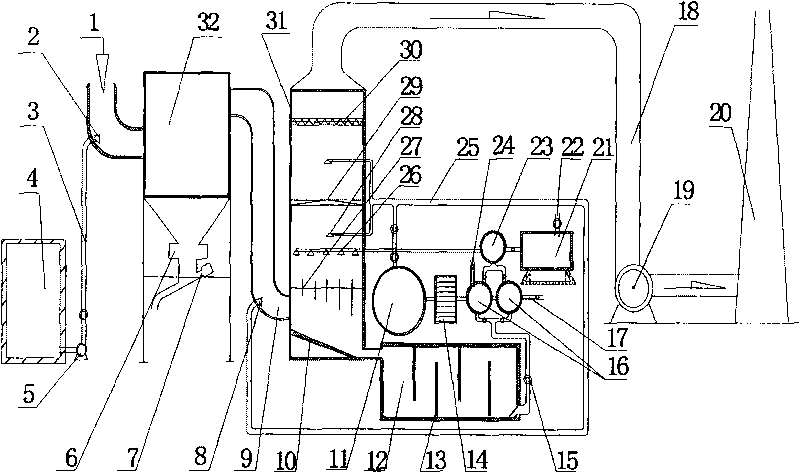

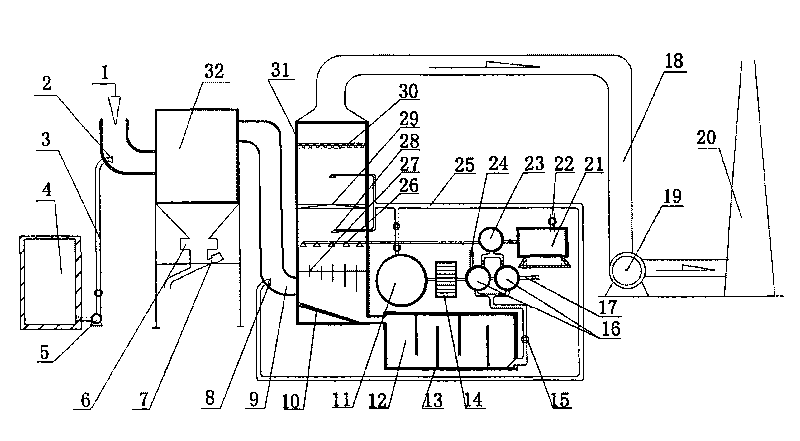

[0028] Such as figure 1 As shown, a method for closed loop desulfurization and denitrification and recovery of sulfur resources, the method includes the following steps:

[0029] The first step, dust removal: a dust collector 32 is installed at the flue 1 at the rear of the boiler flue gas outlet, and installed downwind in the flue 1 of its air inlet, supplied by the water tank 4 through the high-pressure pump 5 and the water pipe 3 The flow of clean water is adjusted through the valve on the water pipe 3, and the water pipe 3 is connected with the atomizing nozzle 2, which is powerfully atomized to increase the full affinity of the gas, solid, and liquid phases. The ash hopper 6 installed under the dust collector 32 is connected to the ash hopper 7, and the outlet of the ash hopper 7 recovers the required dry (or semi-dry, wet) dust. Resour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com