Steel bridge floor cracking inhibition paving structure and construction method thereof

A construction method and steel bridge deck technology, applied to bridges, bridge parts, bridge construction, etc., can solve problems such as pit damage, frequent maintenance, and low strength of the bonding layer, so as to save construction cost, reduce maintenance cost, and improve the construction process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

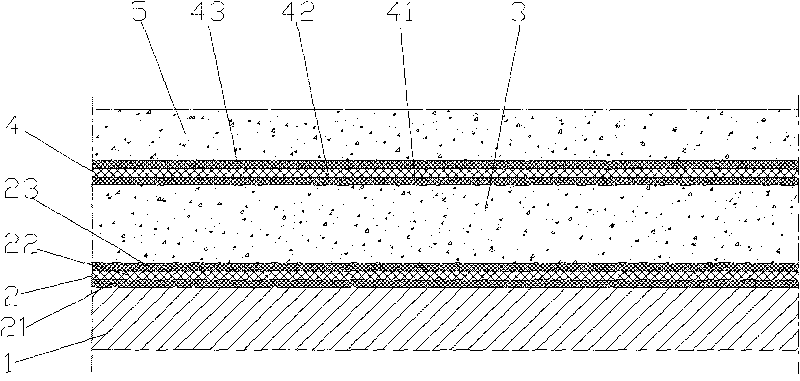

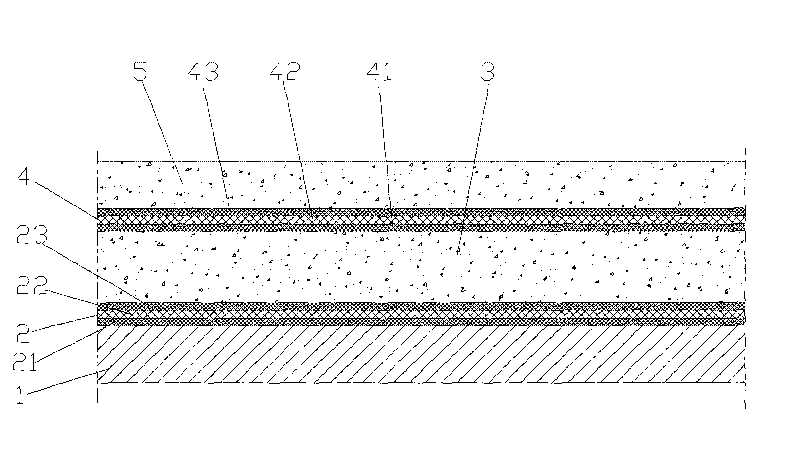

[0034] Accompanying drawing is the structure schematic diagram of the present invention, as shown in the figure: the steel bridge deck crack resistance pavement structure of the present embodiment comprises steel bridge deck 1 and bridge deck pavement structure, and described bridge deck pavement structure comprises The crack-resistant and waterproof adhesive layer I2 on the upper surface of the bridge, the crack-resistant and waterproof adhesive layer I2 is firmly combined from bottom to top, including the lower adhesive layer I21 and the crack-resistant layer I22, the lower adhesive layer The material of I 21 is a polymer, and the material of the crack resistance layer I 22 is fiber reinforced plastic (FRP).

[0035] In this embodiment, an upper adhesive layer I 23 is also provided on the crack-resistant layer I, and the material of the upper adhesive layer I 23 is a polymer; further increasing the bonding of the crack-resistant and waterproof adhesive layer I 2 Strength, im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com