Method for recycling pure-breed fermented pickle juice

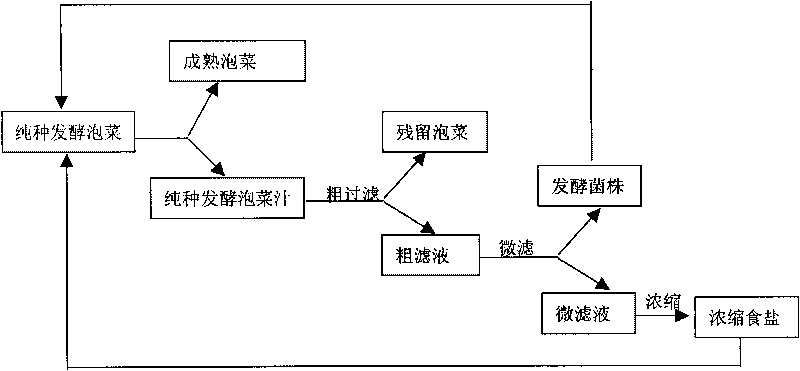

A purebred fermentation and kimchi juice technology is applied in the field of clean production of kimchi, recycling of kimchi juice, and recycling of purebred fermented kimchi juice, so as to achieve the effects of promoting clean production, avoiding waste and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1). Inoculate the concentration of Lactobacillus plantarum to 10 4 The pure fermented kimchi juice after vegetable fermentation with CFU / mL is coarsely filtered with a 50-mesh screen to remove residual vegetables, and the filtrate is collected for microfiltration treatment. The obtained residual vegetables can be used for the production of flavor seasonings or fermented vegetable powder.

[0019] 2). The filtrate after coarse filtration is collected by an inorganic ceramic membrane microfiltration device to collect fermentation strains. Use an alumina inorganic ceramic membrane (membrane pore size 3 μm) that is sterilized at 120°C for 30 minutes, and then filter with a filtration pressure of 0.1MPa and a filtration area of 10M 2 , the filtration time is 90min and the coarse filtrate is filtered, and the obtained concentrated fermented strain (the survival rate of the strain reaches 58%) is reused for preparing fermented vegetables, and the filtrate is used for collect...

Embodiment 2

[0022] 1). Inoculate the concentration of Streptococcus lactis at 10 9 CFU / mL for vegetable fermentation After pure fermented kimchi juice was coarsely filtered with a 200-mesh screen to remove residual vegetables, the filtrate was collected for microfiltration, and the obtained residual vegetables could be used for the production of flavor seasonings or fermented vegetable powder.

[0023] 2). The filtrate after coarse filtration is collected by an inorganic ceramic membrane microfiltration device to collect fermentation strains. Use a silicon oxide inorganic ceramic membrane (membrane pore size 0.01μm) that is sterilized at 130°C for 15min, then filter with a filtration pressure of 0.25MPa and a filtration area of 20M 2 The coarse filtrate was filtered for 30 minutes, and the obtained concentrated fermented strain (the survival rate of the strain reached 90%) was reused to prepare fermented vegetables, and the filtrate was used to collect salt.

[0024] 3). The filtrate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com