Self-discharging cylinder micro/nano-grade sieve air-flotation system for sewage treatment

A technology for sewage treatment and automatic slag discharge. It is used in water/sewage multi-stage treatment, flotation water/sewage treatment, water/sludge/sewage treatment, etc. problems, to achieve the effect of improving air flotation efficiency, improving air flotation efficiency and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

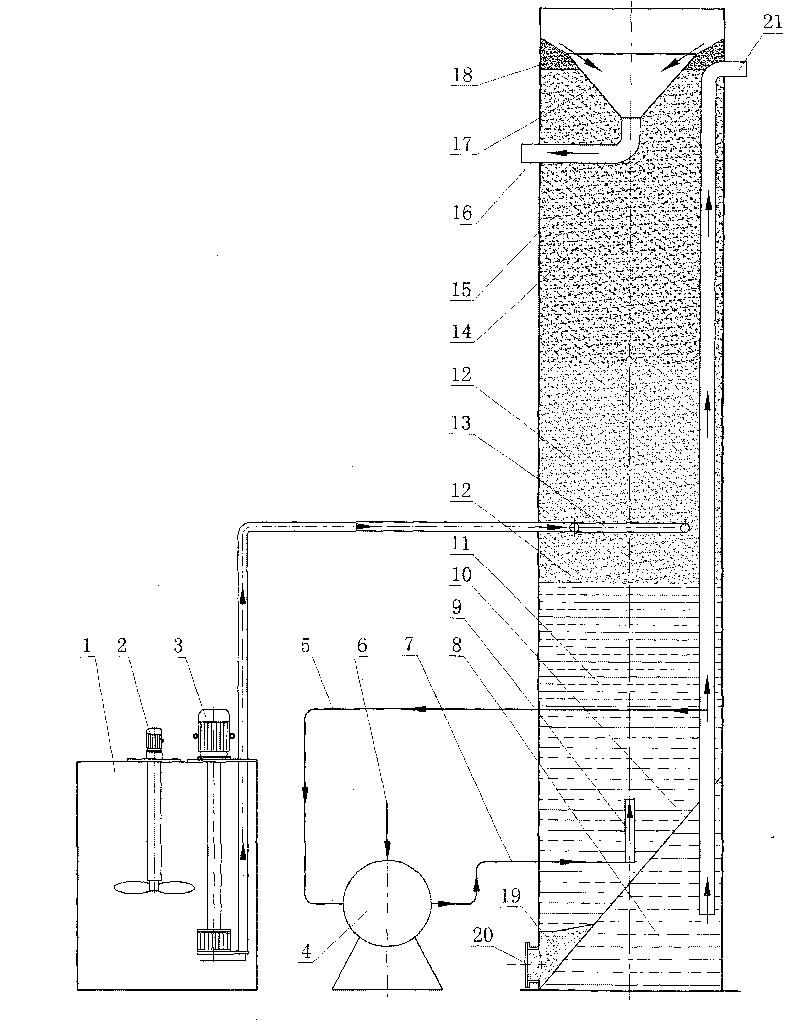

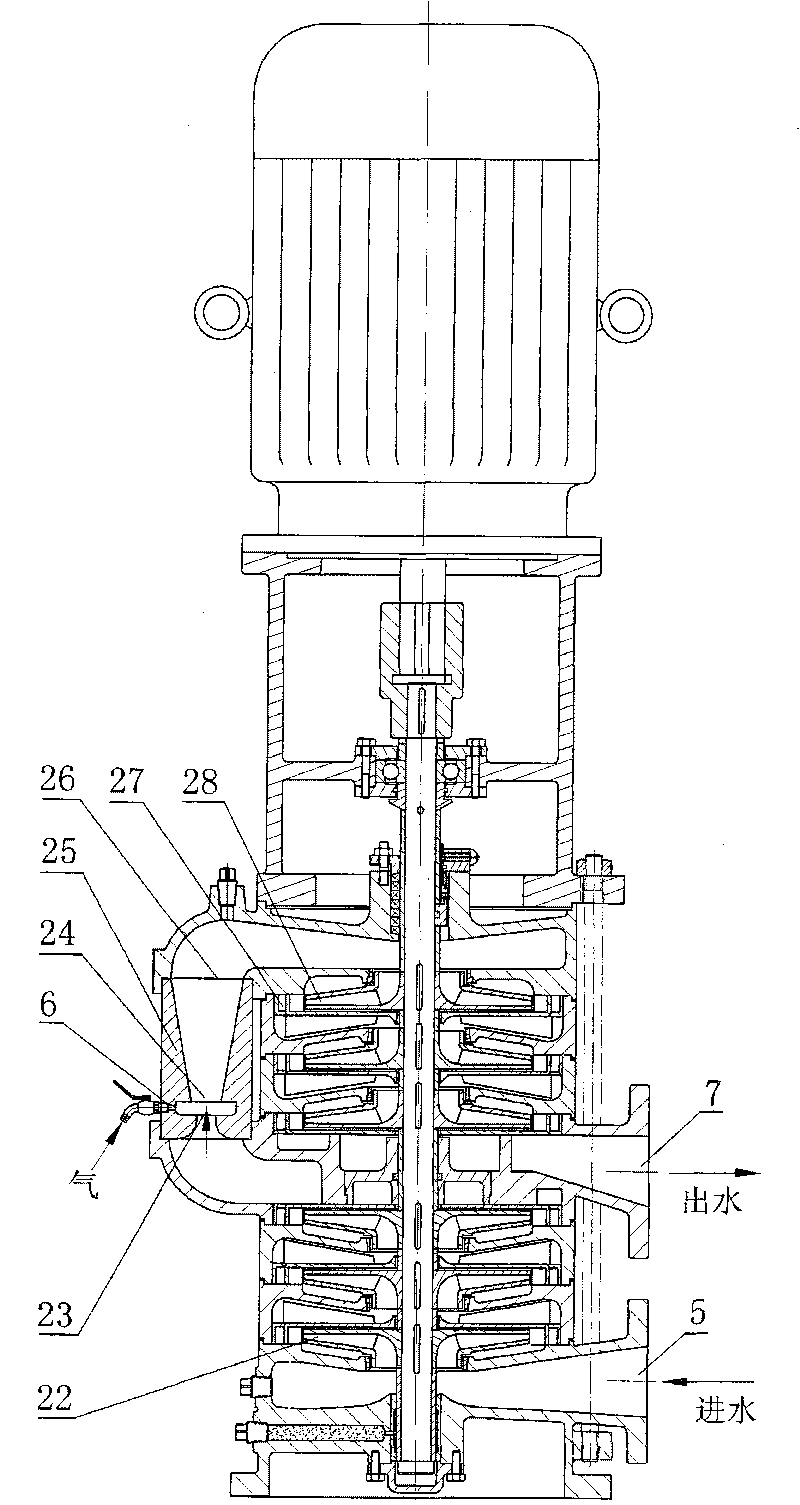

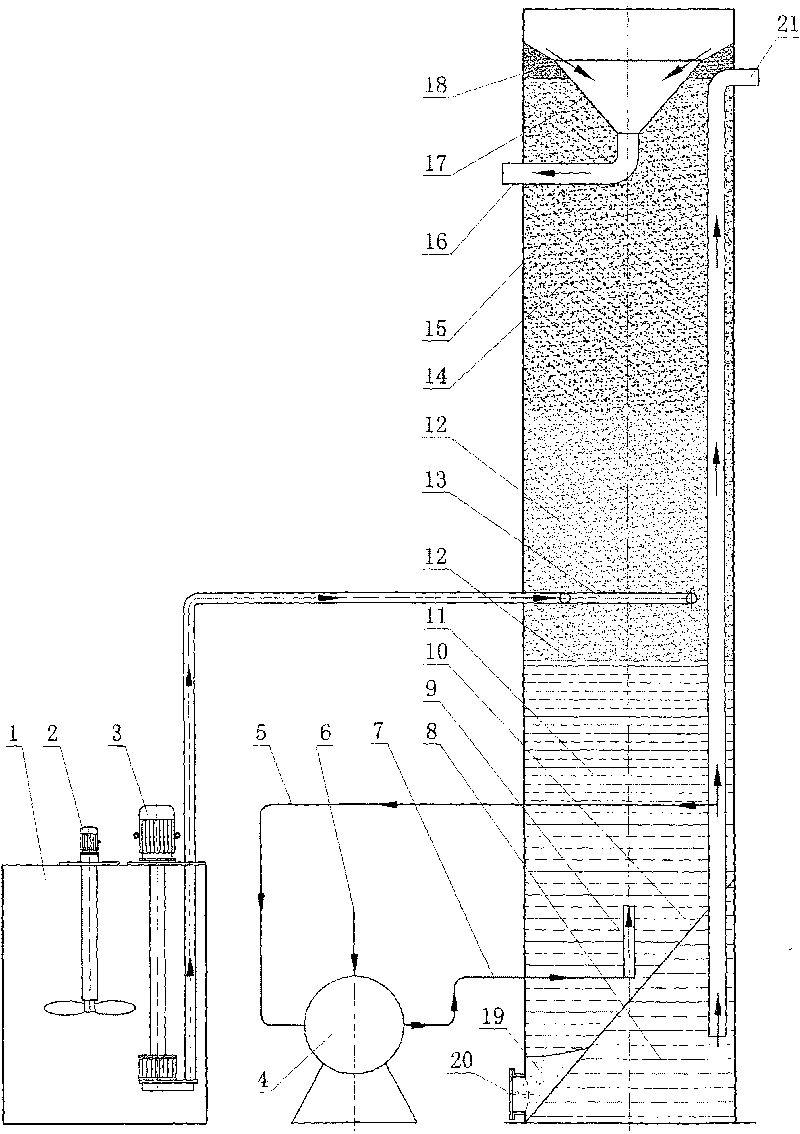

[0010] The air flotation system for automatic slag discharge cylinder type micro-nano sieve sewage treatment according to the present invention is further described by the following components:

[0011] 1. After the sewage enters the sewage mixing and flocculation bucket 1, add 3 to 5 ten thousandths of flocculant to the sewage in the bucket according to the weight part, and stir it with the low-speed mixer 2 to form suspended flocs in the sewage, and the hanging type submerged sewage pump 3 will The flocculated sewage is sent into the air buoy 15 through the sewage distribution pipe 13, and the sewage is evenly distributed in the middle and lower part of the micro-nano sieve sewage treatment air buoy 16. The hanging type submerged sewage pump 3 is that the pump works under the liquid and the motor is above the water surface, which ensures safety and smooth delivery, low noise and stirring effect.

[0012] 2. At the bottom of the cylindrical or square air pontoon, there is a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com