Preparation method of soybean meal polyurethane foam

A technology of foamed plastics and polyurethane, which is applied in the field of preparation of bio-based degradable polyurethane foamed plastics, can solve the problems of high cost of polyurethane foamed plastics, low added value of soybean meal-based products, and low utilization rate of soybean meal, so as to achieve low raw material cost and low cost Low, wide-source effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

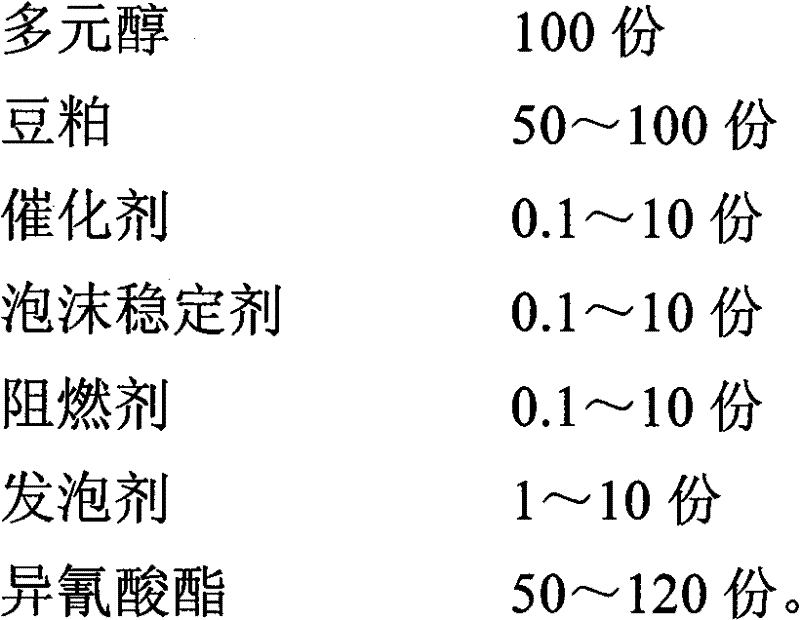

Method used

Image

Examples

Embodiment 1

[0033] 1) Add 60g of soybean meal and 60g of polypropylene glycol into container A, stir for 30min, and mix well; add 0.6g of stannous octoate, 0.4g of triethylamine, 2g of silicone oil, 1g of trimethyl phosphate, and 0.5 g, continue to stir for 30min to make it evenly mixed.

[0034] 2) Weigh 20g of toluene diisocyanate and 10g of diphenylmethane diisocyanate in container B, stir well, quickly add to container A under high-speed stirring, then add 2g of water, stir at 3000 rpm for 6s, and quickly pour into the pre-prepared Foaming is carried out in a mold, and the soybean meal polyurethane foam is obtained after being solidified and molded after being placed for 30 minutes.

Embodiment 2

[0036] 1) Add 60g of soybean meal and 72g of polyethylene glycol-40072g into container A, stir for 10min to make it fully mixed; add 0.5g of triethylenediamine, 0.8g of dibutyltin dilaurate, 2g of silicone oil, methylphosphonic acid Dimethyl ester 1g, continue to stir for 30min, make it fully mix evenly.

[0037] 2) Weigh 52g of polymethylene polyphenyl polyisocyanate in container B, quickly add it into container A under high-speed stirring, then add 1.2g of water, stir at 3000 rpm for 5s, and quickly pour it into the pre-prepared mold for Foaming, standing for 20 minutes to solidify and form, the soybean meal polyurethane foam is obtained.

Embodiment 3

[0039] 1) Add 60g of soybean meal and 90g of polyethylene glycol-400 to container A, stir for 30min to make it fully mixed; add 0.4g of triethylenediamine, 0.8g of dibutyltin dilaurate, 2g of silicone oil, tris(2- Chloroethyl) phosphate 1g, aluminum hydroxide 0.5g, continue to stir for 30min, make it fully mix evenly.

[0040] 2) Weigh 50g of polymethylene polyphenyl polyisocyanate in container B, quickly add it into container A under high-speed stirring, then add 1.2g of water, 1g of cyclopentane, stir at 3000 rpm for 5s, and quickly pour into the pre- Foaming is carried out in the prepared mold, and the soybean meal polyurethane foam is obtained after being solidified and molded after standing for 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com