Cooling device for explosion-proof diesel engine

A diesel engine and cooling device technology, which is applied in the direction of engine cooling, engine components, combustion engines, etc., can solve problems such as unsatisfactory, spontaneous combustion and safety accidents, and obstacles to the normal operation of diesel engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

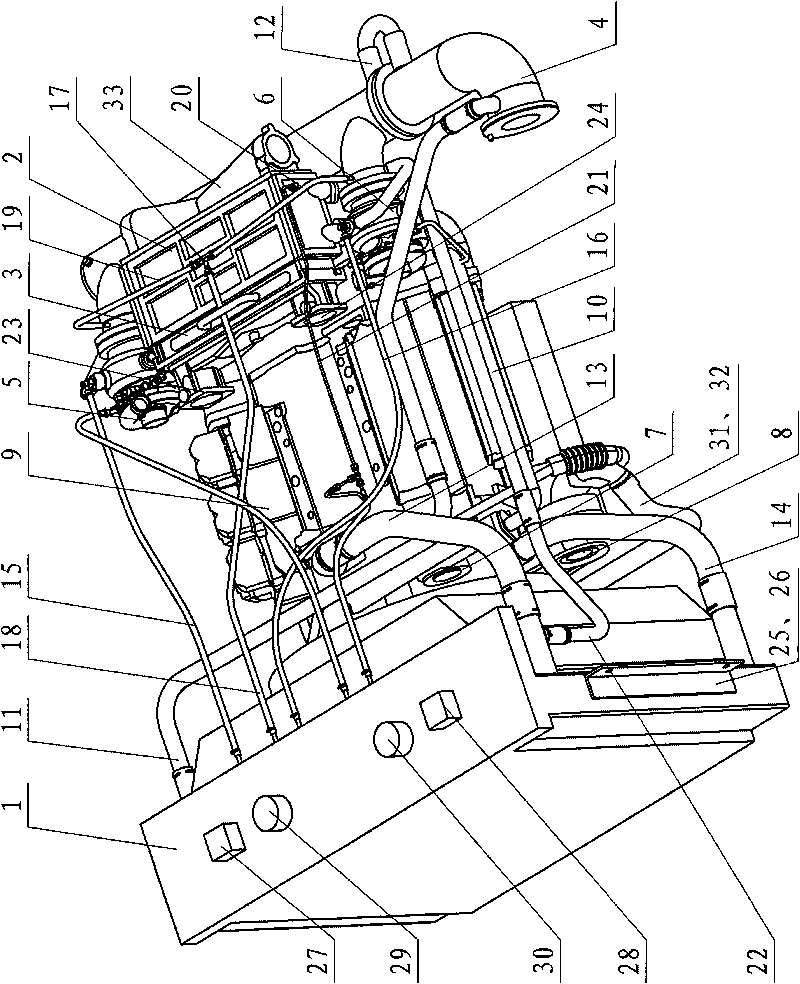

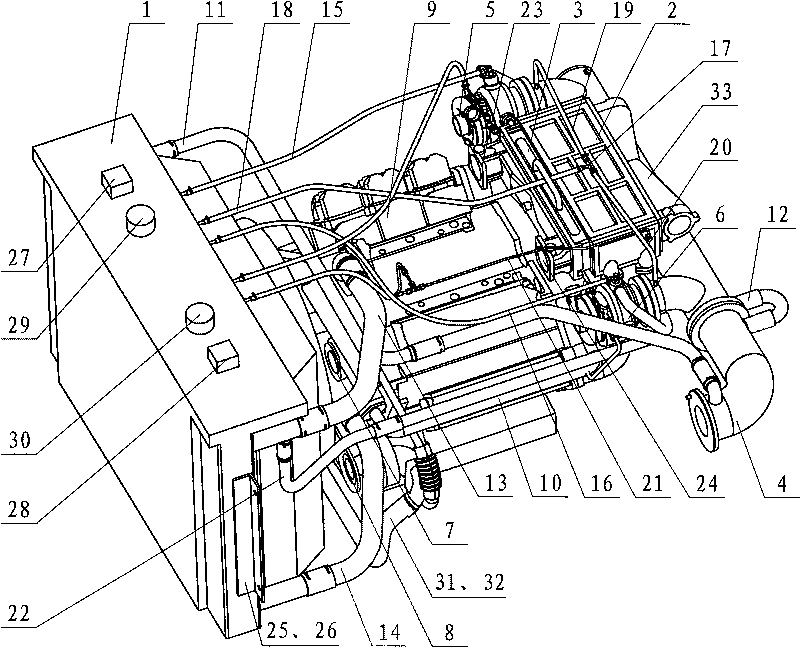

[0017] figure 1 Shown is the overall structure diagram, the position and connection relationship of each part must be correct, and the installation should be firm.

[0018] The water-cooled radiator is equipped with a fan to dissipate heat. The water-cooled radiator is connected to the left and right water-cooled superchargers through the left and right exhaust manifolds. After the water is pressurized, it enters the water-air cooler, and the middle is connected by a pipeline to form a double cycle cooling inside and outside. It can act as a fire retardant.

[0019] All connecting pipes must be unblocked.

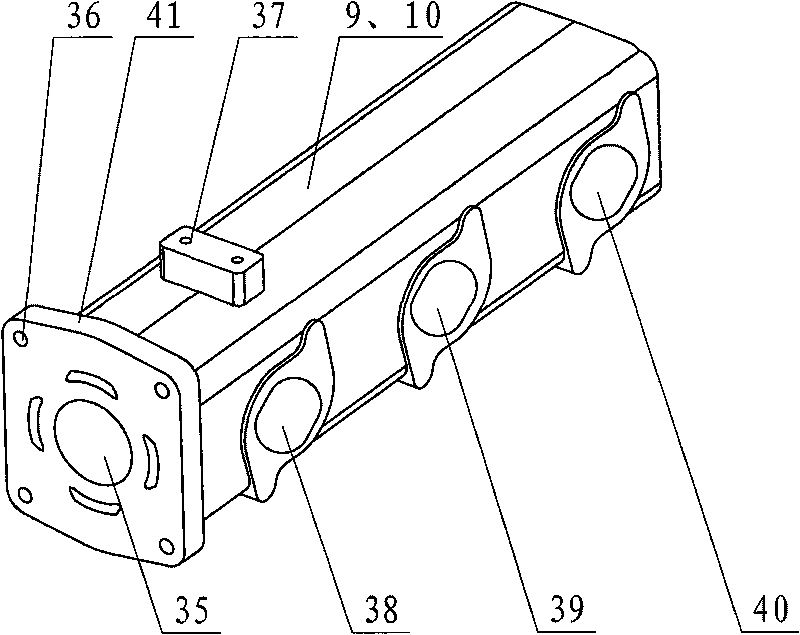

[0020] figure 2 Shown is the structure diagram of the exhaust manifold. There are two exhaust manifolds. The left and right exhaust manifolds have the same structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com