Device and method for diagnosing cylinder of diesel engine

A diagnostic device and technology for diesel engines, applied in the field of detection, can solve problems such as hidden dangers in the operation of diesel engines, large maintenance intervals, and short maintenance intervals, so as to improve the level of modern management and maintenance, reduce maintenance costs, and ensure safe operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

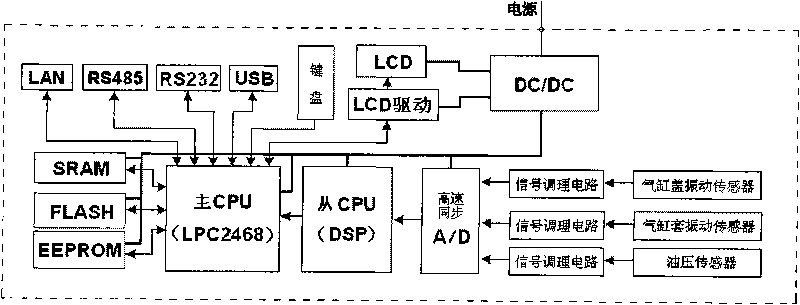

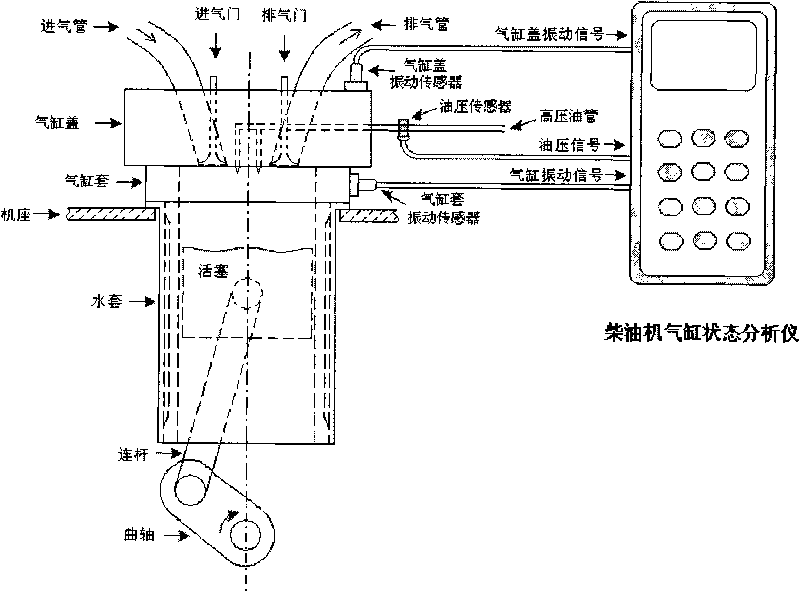

[0037] as attached Figure 1-7A kind of diesel engine cylinder diagnosis device of the present invention shown, comprises master CPU, from CPU, high-speed synchronous A / D converter, display device LCD, keyboard, storage device (SRAM, EEPROM, FLASH), communication interface (LAN, RS485, RS232, USB), power conversion device DC / DC, cylinder head vibration sensor, cylinder liner vibration sensor, oil pressure sensor, etc. The main CPU adopts Philips ARM chip LPC2468, which is responsible for operation, display, data management, communication and other functions. The CPU adopts TI’s DSP chip TMS320C5402, which is responsible for real-time high-speed data collection and data processing. The cylinder head vibration sensor and the cylinder liner vibration sensor use a magnetic seat type vibration sensor, with a preamplifier inside, which can be very convenient by relying on magnetic force On-site installation. The cylinder head vibration sensor is installed on the top platform of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com