Ice valve type pressure-maintaining and heat-preservation sampler

A sampler and ice valve technology, applied in the field of pressure-holding and heat-insulating sampling drilling tools, can solve problems such as difficulty in closing ball valves or plate valves normally, occupation of ball valves or plate valves, and low core collection rate, and improve the reliability of pressure-holding and success rate, increasing core diameter, and controllable cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment for further detailed description:

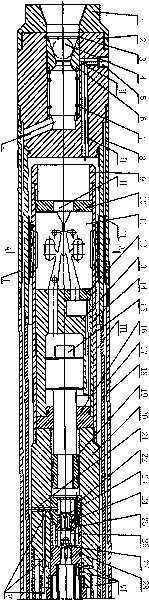

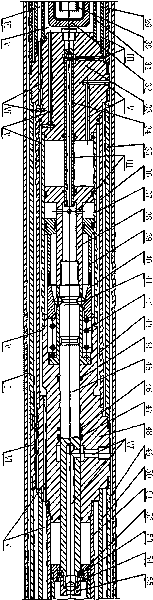

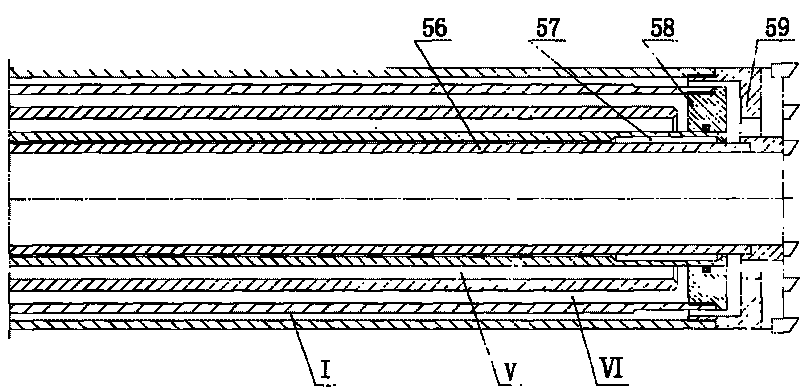

[0031] attached Figure 1a The lower end of the attachment Figure 1b top of the Figure 1b The lower end of the attachment Figure 1c The upper end of the ice valve constitutes a complete ice valve pressure-preserving and heat-preserving sampler.

[0032] The pressure-holding function is realized by the mechanical seal and the ice valve formed under the core tube by the refrigeration of the refrigerant circulation. The heat preservation is realized by coating the surface of the outer wall of the lower 51 of the inner circulation pipe with porous foam plastics, thermal insulation paint and reflective film.

[0033] The ice valve type pressure-preserving and heat-preserving sampler includes: drilling and sampling switching mechanism, refrigerant circulation system, core tube lifting and positioning mechanism, upper mechanical seal mechanism, ice valve forming mechanism, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com