Method and device for detecting purity of trichlorosilane

A technology of trichlorosilane and purity, applied in the field of detecting the purity of trichlorosilane, can solve the problems of increased cost, contamination of epitaxial furnace, etc., and achieves the effects of increasing utilization rate, avoiding economic losses, and being easy to purchase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

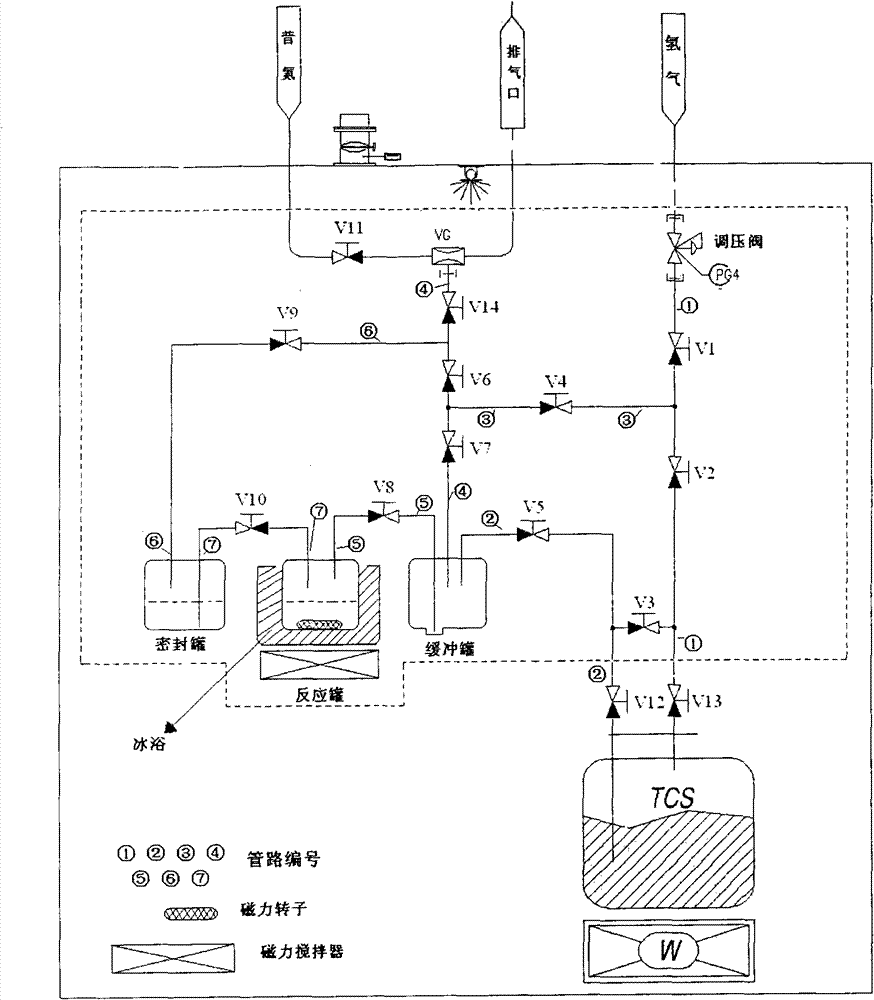

[0033] 1. Cleaning and connection of components: mainly connect the buffer tank and reaction tank to the system after cleaning. Fill a certain amount of pure water in the reaction tank and the sealed tank, the amount of pure water in the reaction tank cannot submerge the ports of pipelines 5 and 7, and the amount of pure water in the sealed tank cannot submerge the ports of pipeline 6. At the same time, a certain amount of pure water needs to be reserved for backup (mainly used for background testing). At the same time, pour the TCS solution to be tested into the system.

[0034] 2. Pipeline cleaning: Since the pipeline connection is completed in the air, impurities and moisture in the air will affect the measurement effect, and the air in the pipeline needs to be replaced by hydrogen. The specific method is:

[0035] a) Keep the valves V1, V10, V12, V13, and V14 in the closed state, and open the valves V2, V3, V4, V5, V6, V7, V8, V9, and V11.

[0036]b) Vacuumize the syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com