Dynamic desorption process for gold-loaded carbon

A gold-loaded carbon and desorption technology, which is applied in the petroleum industry, filter regeneration, filtration and separation, etc., can solve the problems of uneven and channeled desorption, achieve high mass and heat transfer rates, and shorten the desorption time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

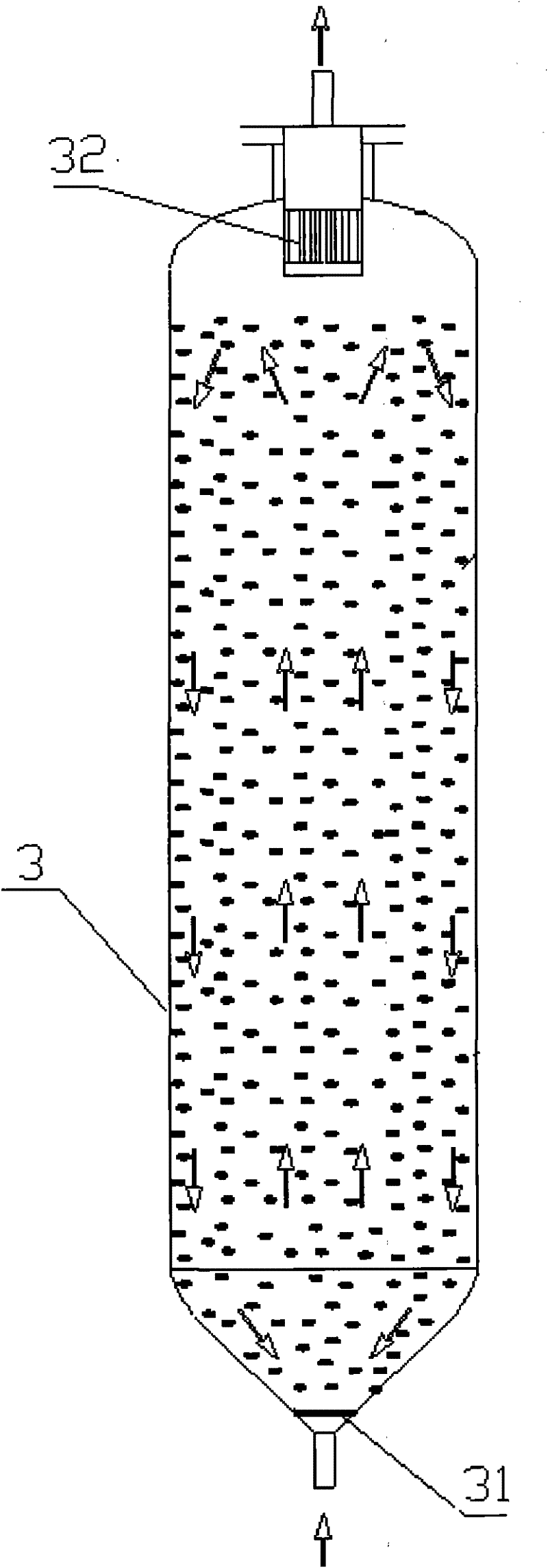

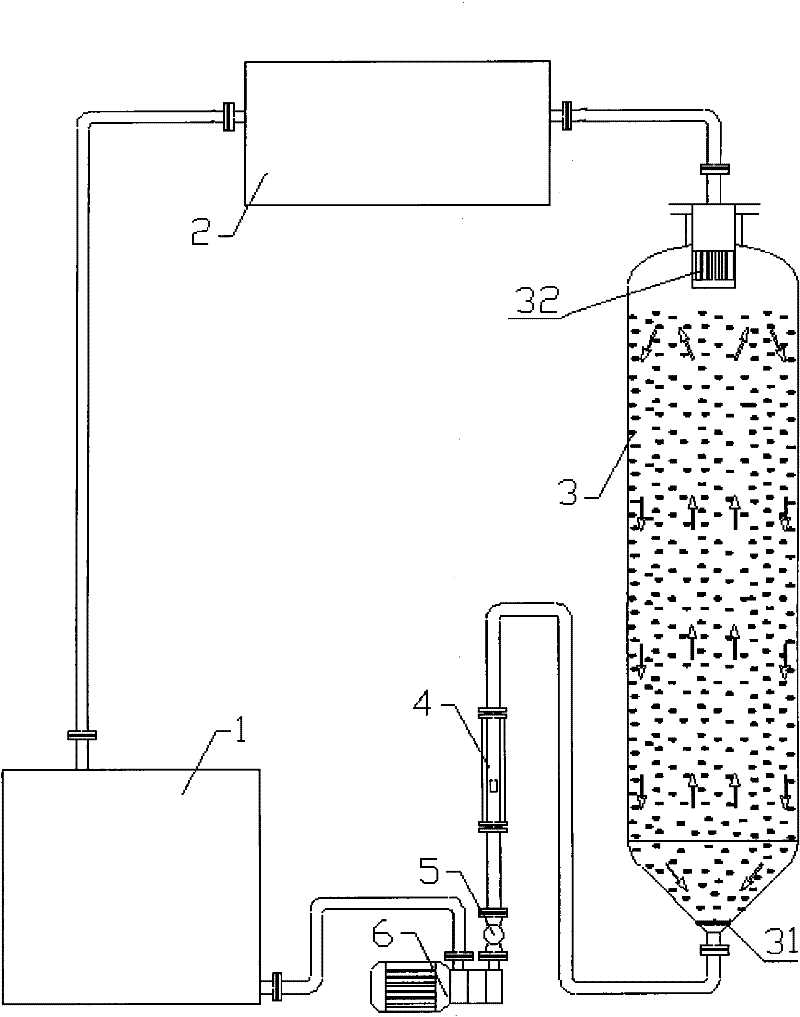

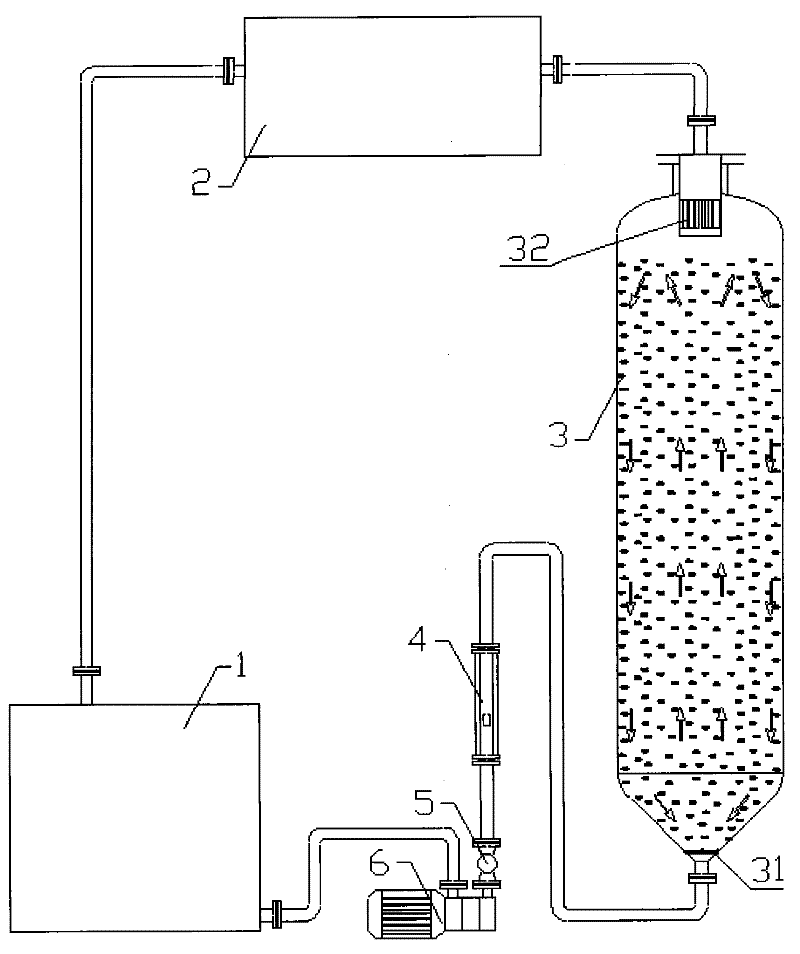

[0018] see figure 1 with figure 2 As shown, the gold-loaded carbon is in a loose suspension state when the desorption liquid flows through, forming a liquid-solid two-phase circulating fluidized bed. In the dynamic desorption of this fluidized bed, the gold-loaded carbon particles in the axial center of the desorption device 3 While tumbling, it moves upward continuously under the action of the speed of the desorption liquid. Due to the action of fluid resistance, when it reaches the top, that is, the highest interface of the fluidized bed, it flows to the surroundings and flows downward along the peripheral wall of the desorption device. When it reaches the bottom, it gathers into the center through the cone bottom. The inlet of the desorption liquid enters a new round of circulation again upwards, and goes round and round to form a circular fluidized dynamic desorption.

[0019] see figure 1 As shown, the bottom of the desorption device 3 is a vertebral body, and the incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com