High-pressure water descaling system

A high-pressure water descaling and descaling nozzle technology, applied in the field of hydraulic descaling devices, can solve the problems of easy rework and waste of resources, and achieve the effect of simple and reliable positioning, stable and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

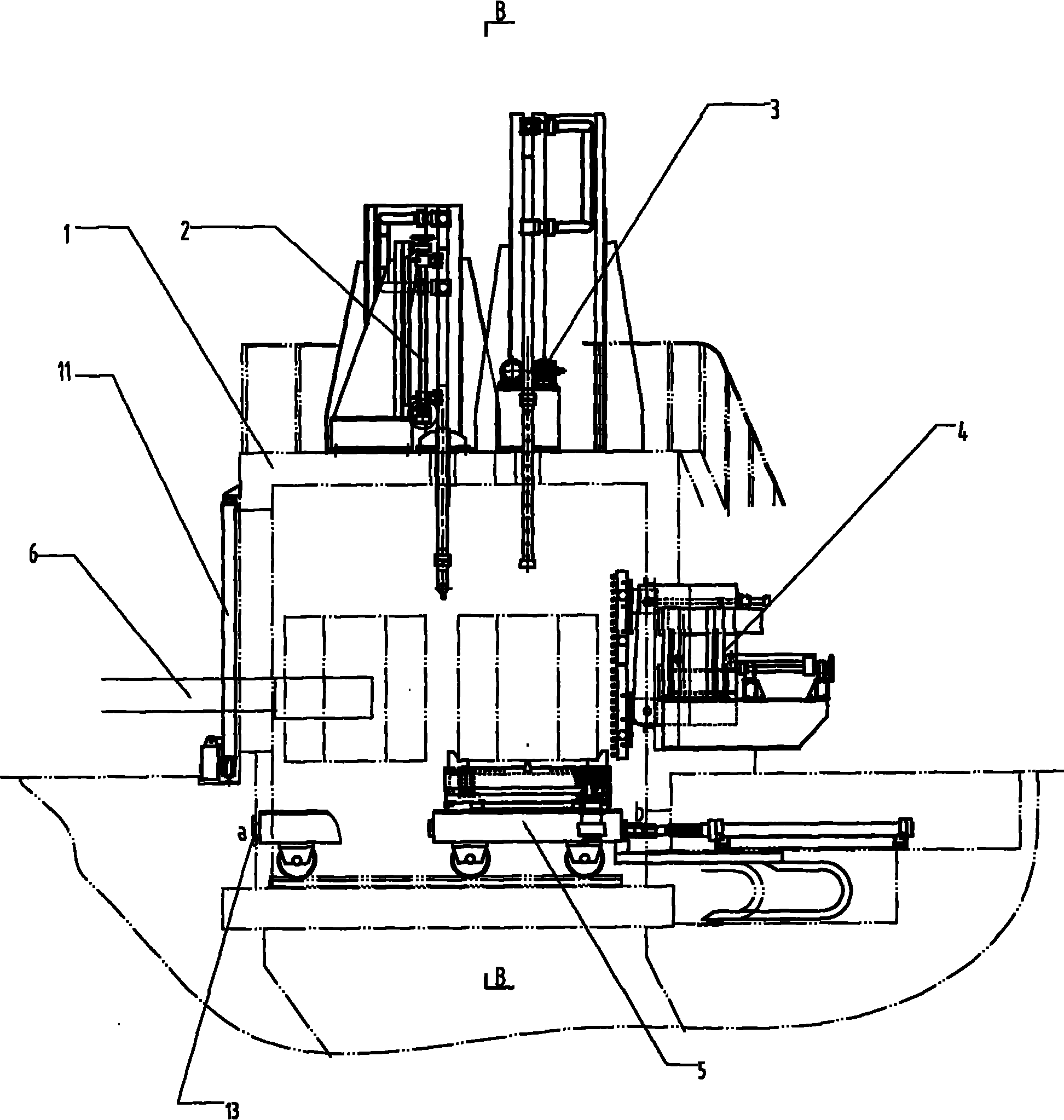

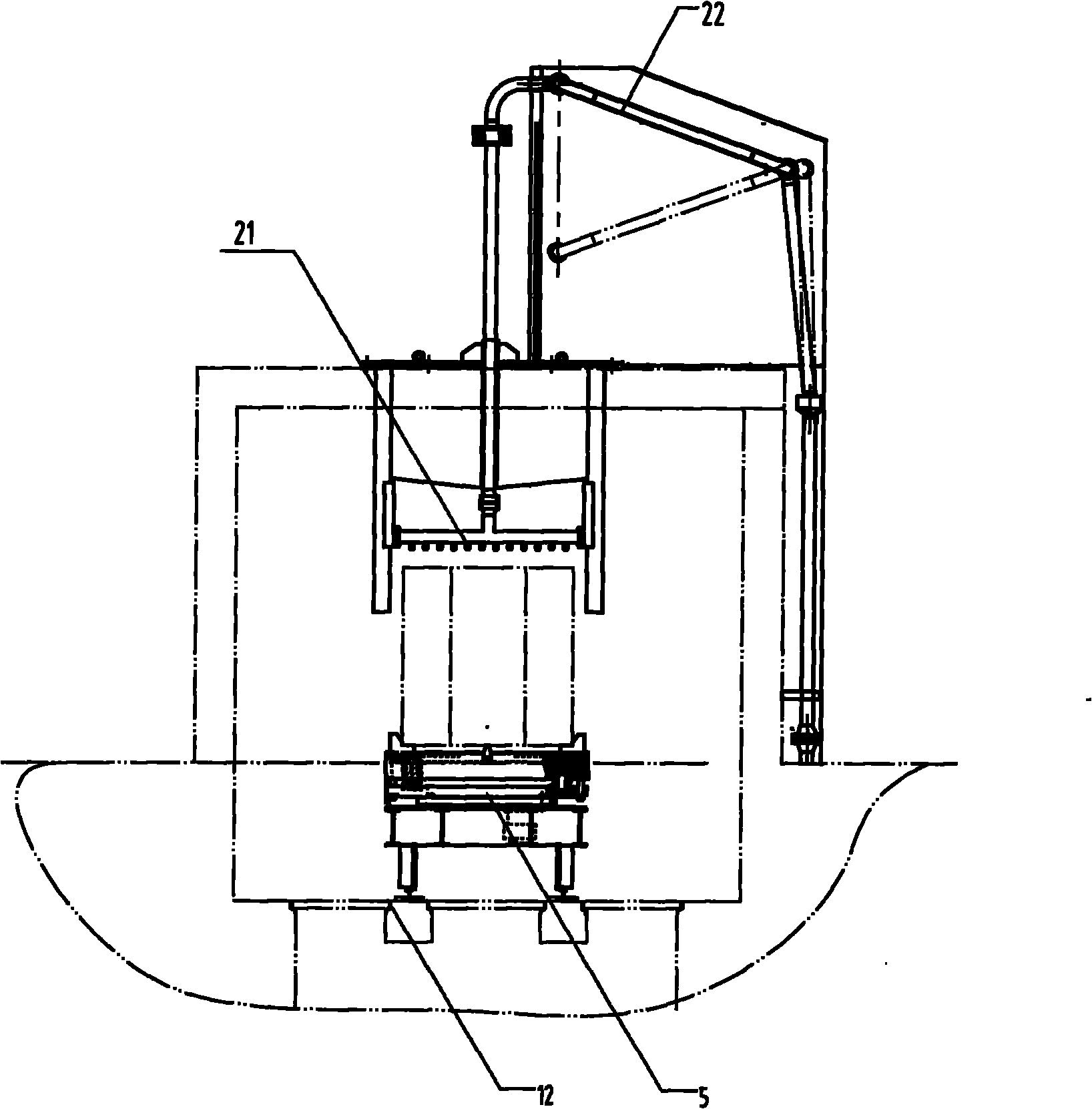

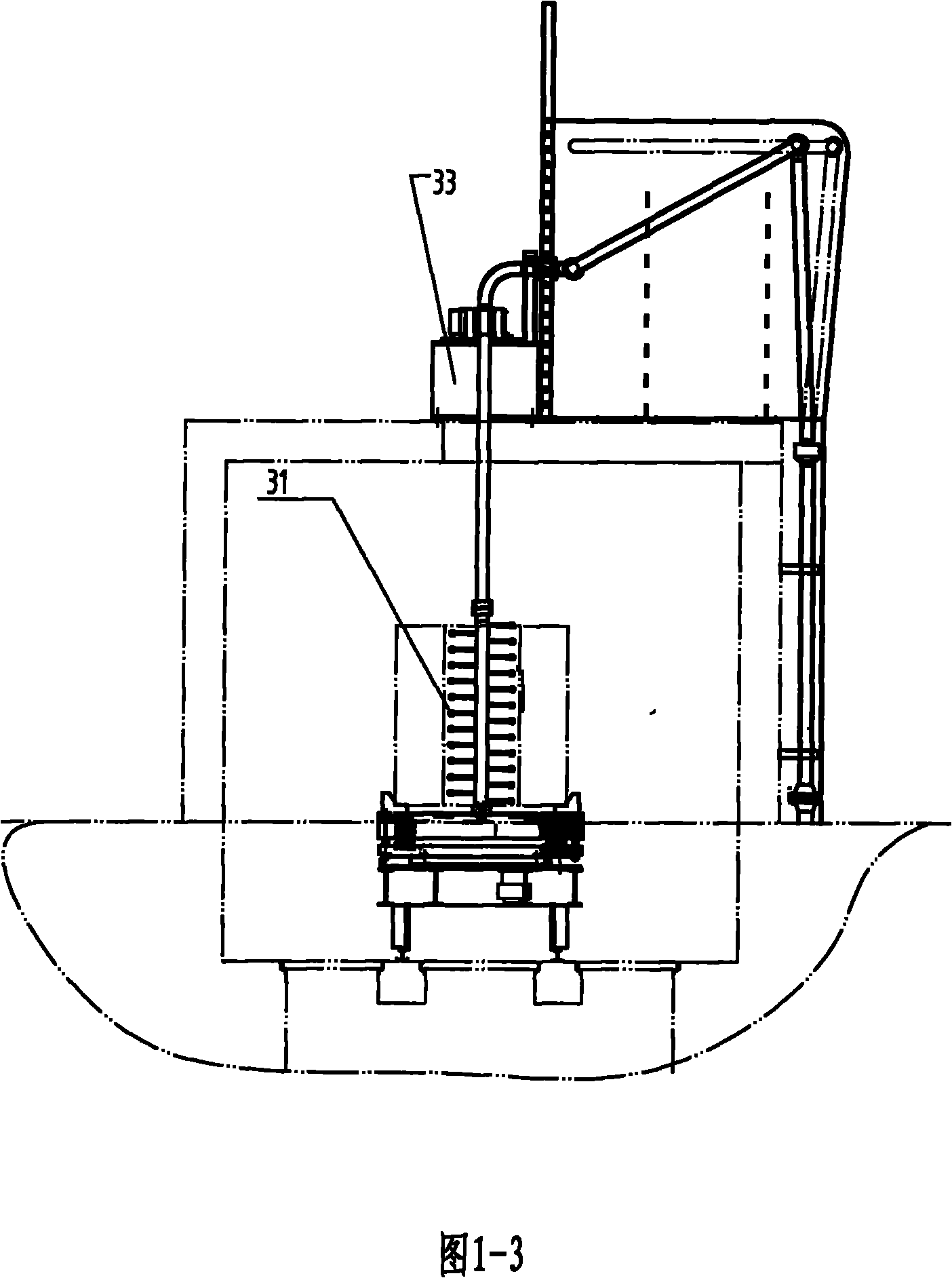

[0035] Attached below Figure 1-5 The present invention will be described in detail. The hydraulic cylinders, hydraulic motors, fully automatic control systems, monitoring systems and water circulation pipelines used in the present invention are all commercially available products.

[0036] see Figure 1-5 As shown, a high-pressure water descaling system is used to descale the inner, outer and upper surfaces of steel ingots or circular billets, including high-pressure water pump stations, water circulation pipeline systems, descaling devices and control systems (control systems, The high-pressure water pump station and the water circulation pipeline are the same as the existing products, not shown in the figure), wherein the descaling device consists of a descaling chamber 1, an upper surface descaling mechanism 2, an inner hole descaling mechanism 3, an outer surface descaling mechanism 4, The descaling car 5 and the backwater ditch are jointly composed. One side of the des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com