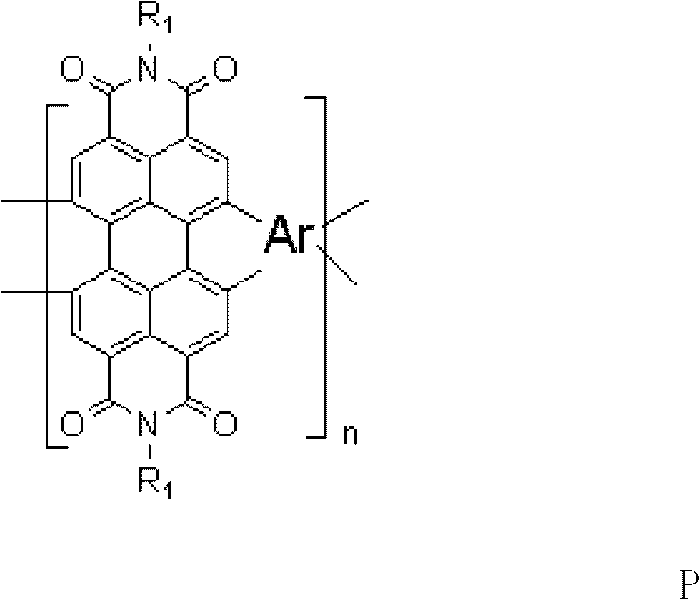

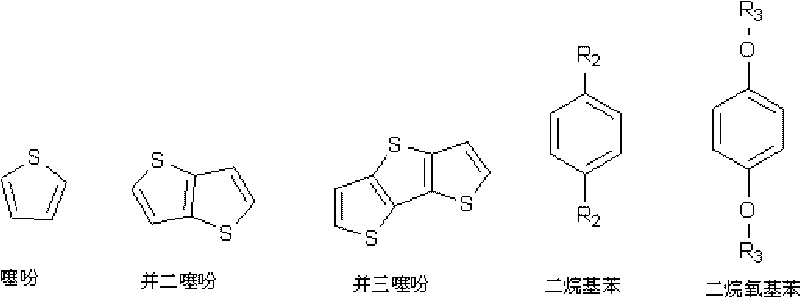

Trapezoidal conjugated polymer and method for preparing same

A technology of conjugated polymers and trapezoids, which is applied in the field of trapezoidal conjugated polymers and its preparation, can solve problems such as poor optical stability, no perylene imide, and limitations of synthesis methods, and achieve increased optical stability and conjugated polymers. increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

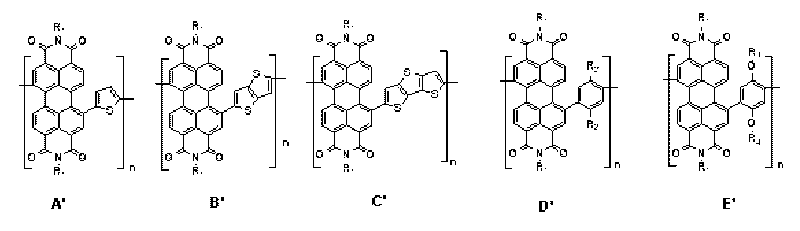

[0028] The preparation of embodiment 1 raw material A'-1

[0029]

[0030] In a 50mL flask, add 885mg F-1 (1mmol), 409mg G (1mmol), 20mL toluene, 20mgPd(PPh 3 ) 4 , 100 ° C, under argon atmosphere, the reaction was stirred for 48h. The reaction mixture was added into n-hexane, and an ink-colored solid was precipitated, filtered, and the filter cake was dried to obtain 780 mg of a black solid, with a yield of 96%, which was Polymer A'-1. The number average molecular weight is 11200, and the dispersion index is 1.35 (chloroform is the mobile phase, polystyrene is the standard).

Embodiment 2

[0031] The preparation of embodiment 2 ladder-shaped conjugated polymer A-1

[0032]

[0033] In a 250mL flask, add 300mg of polymer A'-1, 100mL of toluene, 10mg of iodine, in the presence of air, under sunlight, reflux for 8h, add the reaction mixture into n-hexane, precipitate a black solid, filter, and dry the filter cake to obtain black The solid was 296 mg, and the yield was 99%, which was the ladder polymer A-1. The number average molecular weight is 12100, and the dispersion index is 1.30 (chloroform is the mobile phase, polystyrene is the standard).

Embodiment 3

[0034] The preparation of embodiment 3 raw materials B'-1

[0035]

[0036] In a 50mL flask, add 1665mg F-2 (1mmol), 465mg K (1mmol), 30mL toluene, 25mgPd(PPh 3 ) 4 , 100 ° C, under argon atmosphere, reacted for 72h under stirring conditions. The reaction mixture was added into n-hexane to precipitate a black solid, which was filtered and the filter cake was dried to obtain 1545 mg of a black solid with a yield of 94%, which was Polymer B'-1. The number average molecular weight is 18500, and the dispersion index is 1.27 (chloroform is the mobile phase, polystyrene is the standard).

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com