Device and method for measuring volume ratio of vacuum container by linear vacuometer

A technology of vacuum container and vacuum gauge, which is applied in the field of measurement, can solve the problems of large influence on the measurement result of pressure change, large measurement uncertainty, and cannot be effectively prevented, so as to achieve small measurement uncertainty, simple method, and avoid unnecessary The effect of certainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

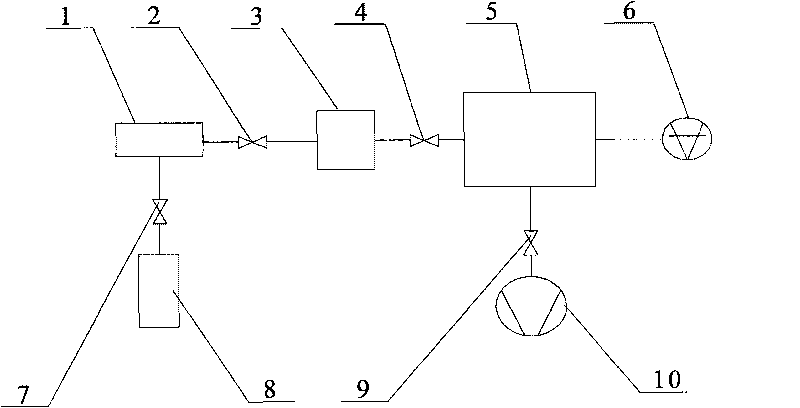

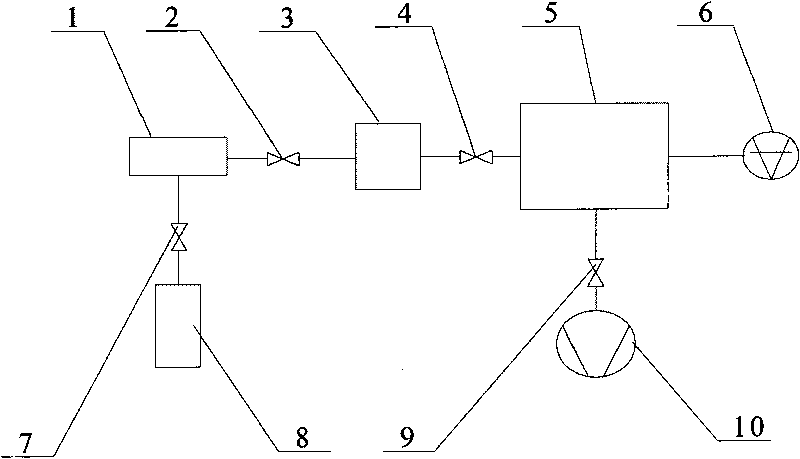

[0025] 1) Turn on the vacuum pump 10, open the vacuum valves 2, 4, 9, the plenum chamber 6 and each connecting pipeline are pumped into a vacuum state, and record the reading p' of the vacuum gauge 6 0 (3.305×10 -5 Pa).

[0026] 2) Close the valve 2, and enter the air into the plenum chamber 1 through the valve 7.

[0027] 3) Close the valve 7, adjust the fine-tuning valve 2, so that the gas flows into the vacuum containers 3 and 5 at a constant pressure, and when the reading of the vacuum gauge 6 no longer changes, record the reading p of the vacuum gauge 6 0 (5.967×10 1 Pa).

[0028] 4) Close the valve 4, open the valve 9, the container 5 is pumped into a vacuum state, and record the reading p' of the vacuum gauge 6 1 (8.634×10 -5 Pa).

[0029] 5) Close the valve 9, open the valve 4, let the gas enter the vacuum container 5, when the reading of the vacuum gauge 6 no longer changes, record the reading p of the vacuum gauge 6 1 (5.793×10 -1 Pa).

[0030] 6) The volume...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com