Device for detecting density of aluminum-nickel-cobalt permanent magnet alloy pressed blanks

A permanent magnet alloy, density detection technology, used in the preparation of test samples, material analysis by measuring buoyancy, etc., can solve the problem of unmeasurable density of hair damage, and achieve simple structure, easy operation and accurate test process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0015] A preferred embodiment is given below:

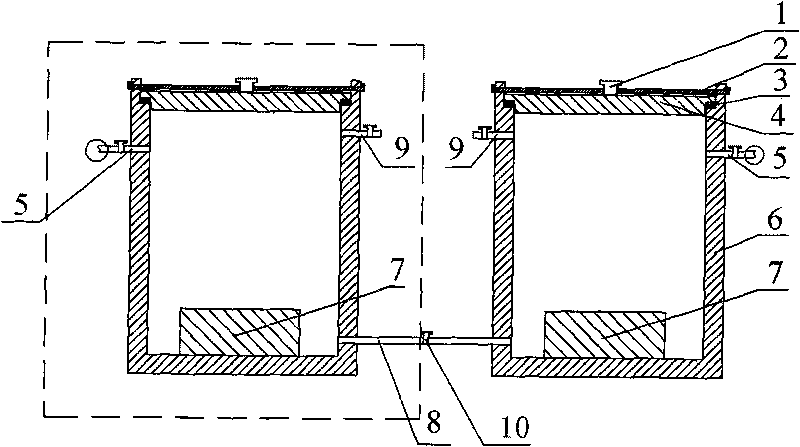

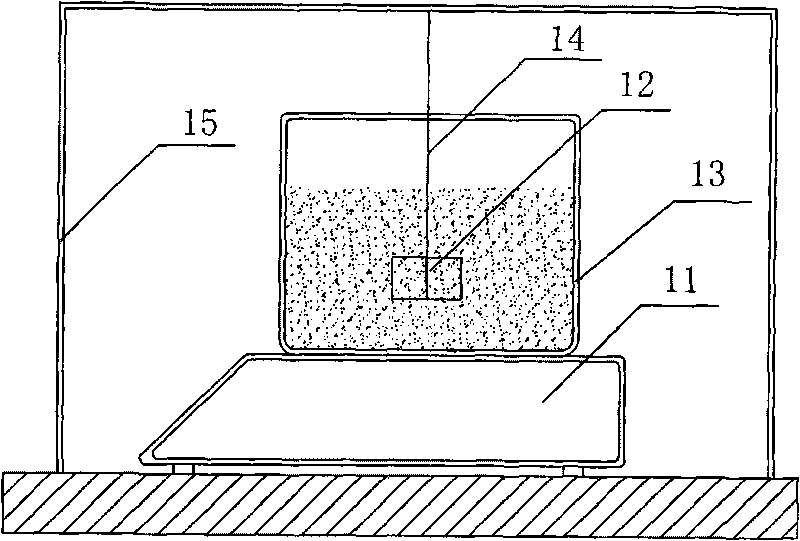

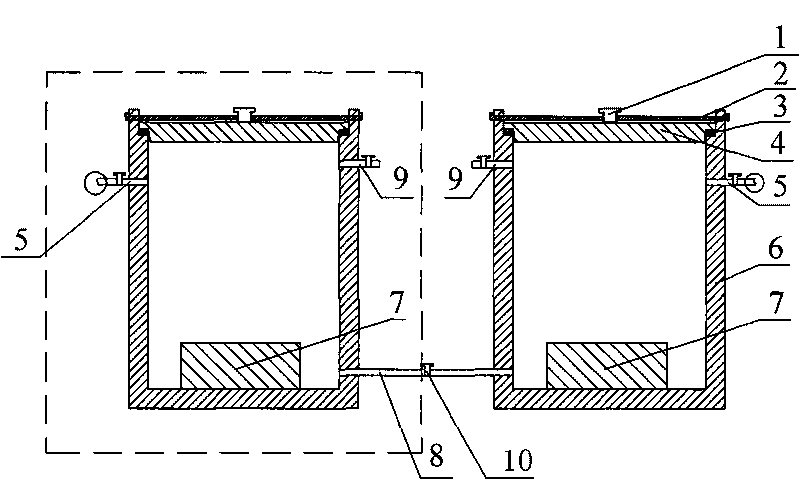

[0016] as attached figure 1 As shown, a density detection device for AlNiCo permanent magnet alloy pressing blanks includes at least two cylinders 6, a cylinder cover 4 is arranged above the cylinder 6, and a clip bar 2 is arranged above the cylinder cover 4, Locking bolts 1 are arranged on the clamping strip 2, a sample table 7 is arranged inside each of the cylinders 6, and the cylinders 6 are connected through a connecting pipe 8 at the bottom, and the connecting pipe 8 is provided with a There is a communication valve 10, and a vacuum stop valve 5 and an air release valve 9 are respectively arranged above the cylinder body 6.

[0017] A sealing ring 3 is arranged between the cylinder cover 4 and the cylinder body 6 .

[0018] Other equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com