Supported nano Au catalyst for preparing crotyl alcohol and preparation method thereof

A technology for producing crotyl alcohol and catalyst, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, preparation of hydroxyl compounds, etc., and can solve the problems of high price, low selectivity of crotyl alcohol, unsuitability for large-scale industrial production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

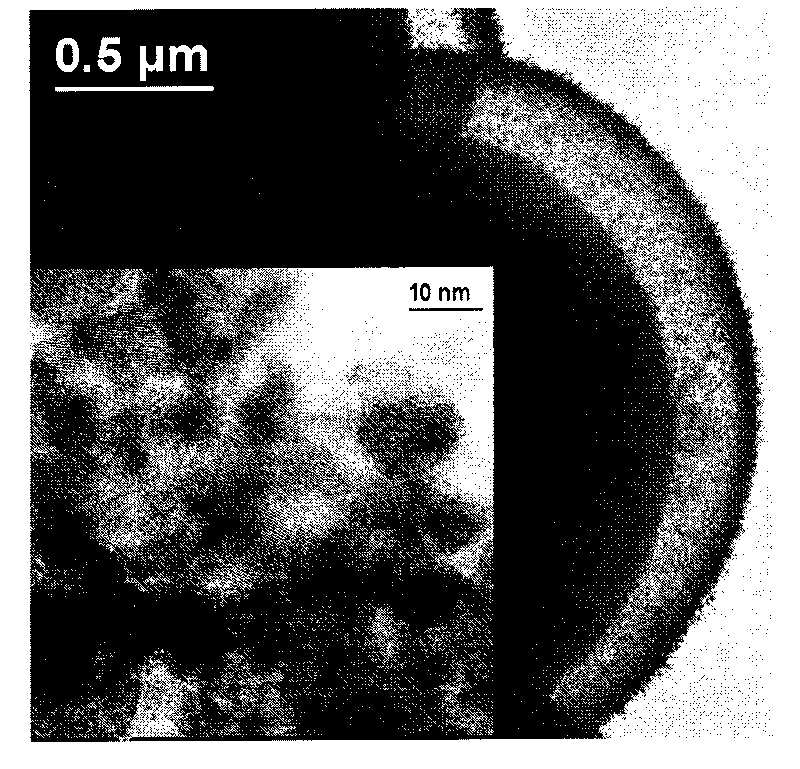

Embodiment 1

[0015] Embodiment 1: at room temperature 1.0g TiO 2 Add 60mL HAuCl to the vehicle 4 4H 2 In the mixed solution of O (0.08M) and urea (8M), slowly heat the solution to 353K with stirring and keep it for 4h; then stir and evaporate the prepared precursor, bake at 393K for 24h; 2 / Ar gas, at 1K·min -1 The heating rate was heated to 673K and kept for 3h. Recorded as 1# catalyst.

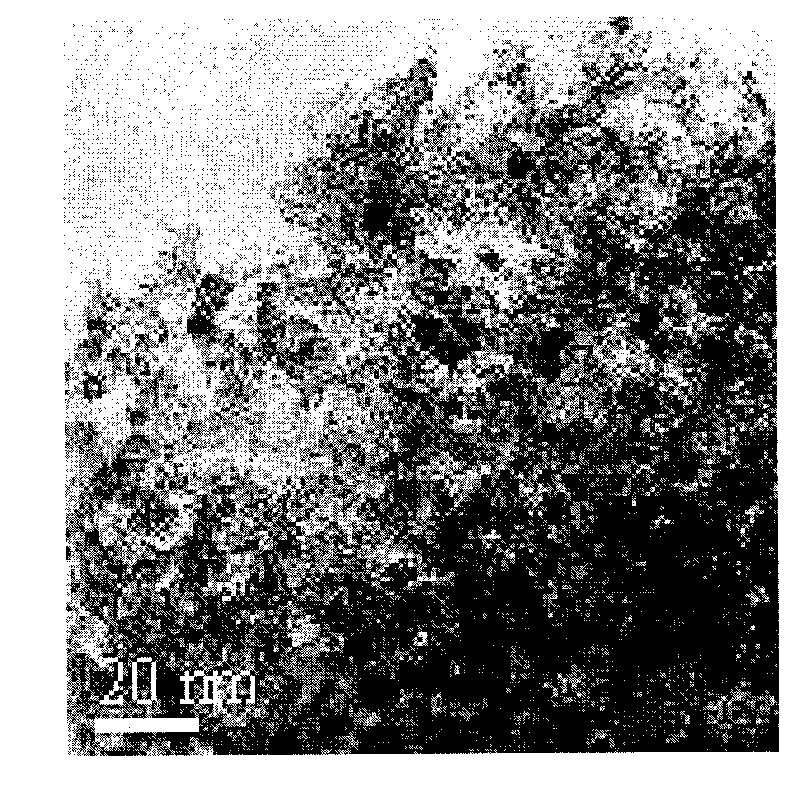

Embodiment 2

[0016] Embodiment 2: at room temperature 1.0g TiO 2 Add 60mLHAuCl to the carrier 4 4H 2 In the mixed solution of O (0.17M) and urea (17M), slowly heat the solution to 353K with stirring and keep it for 4 hours; Recorded as 2# catalyst.

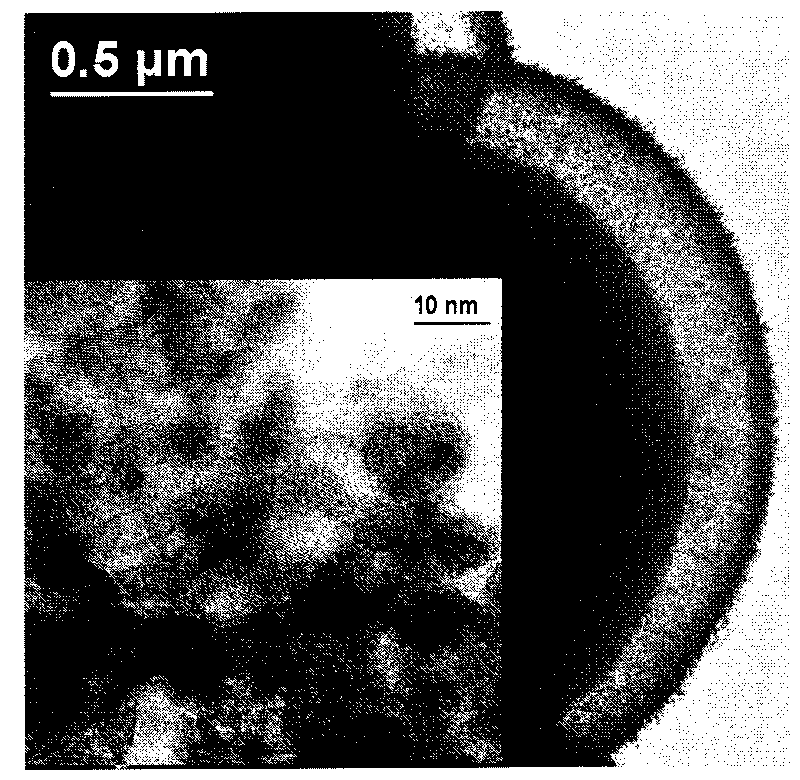

Embodiment 3

[0017] Embodiment 3: 1.0g TiO is mixed at room temperature 2 Add 60mL HAuCl to the vehicle 4 4H 2 In the mixed solution of O (0.42M) and urea (42M), slowly heat the solution to 353K under stirring and keep it for 4h; It is recorded as 3# catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com