Centrifugal scraping plate film formation pyrolysis reaction device and method thereof

A thermal cracking and scraper technology, which is used in non-catalytic thermal cracking, cracking, preparation of liquid hydrocarbon mixtures, etc., can solve the problems of long reaction period, slow heat transfer of grooved rotary cracking reactor, secondary pollution, etc. The superiority of performance is outstanding, overcoming the effect of long reaction period and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

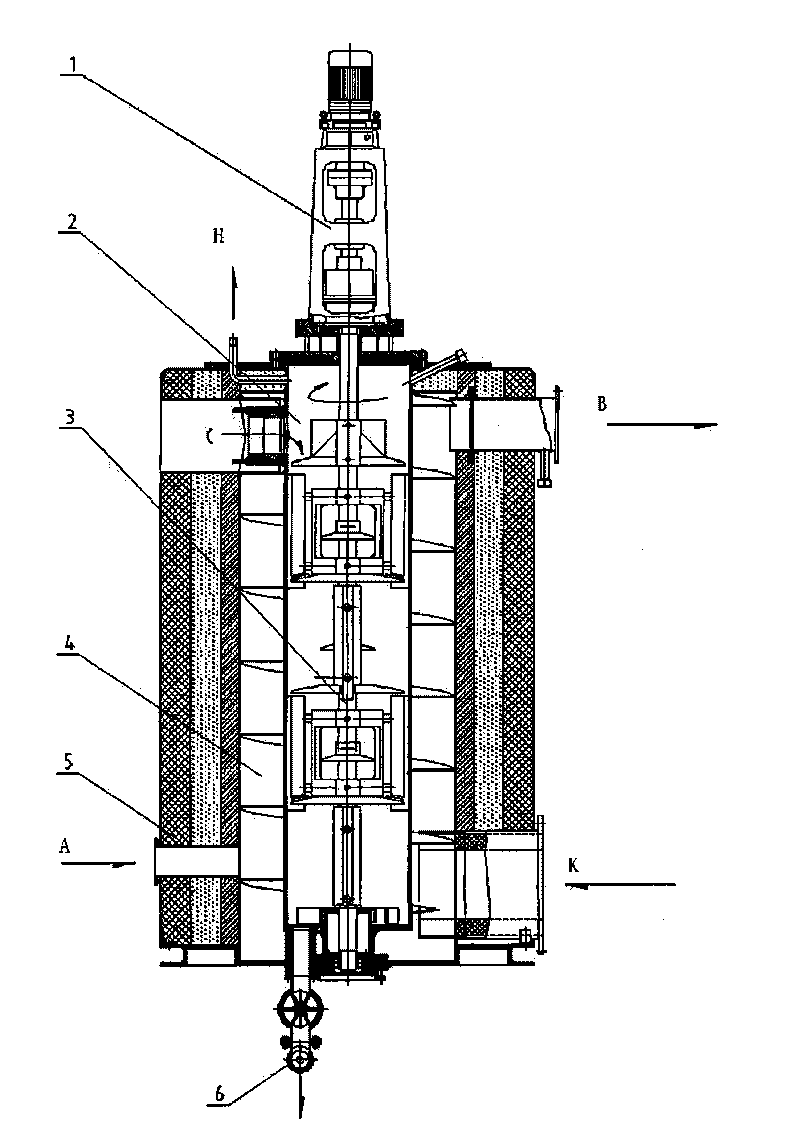

[0024] Such as figure 1 As shown, the centrifugal scraper film-forming pyrolysis reaction device of the present invention includes a furnace body 2, a scraper assembly 3 driven by a reducer 1, a spiral flue 4, a heat preservation cover 5, and a gas-blocking discharge device 6.

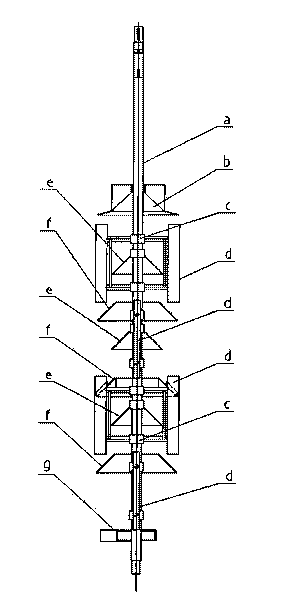

[0025] Such as figure 2 As shown, the scraper assembly 3 is composed of a primary distribution plate b, multiple sets of scrapers d, a scraper frame c, a baffle plate e, a secondary distribution plate f, a discharge plate g and a main shaft a, which is that the main shaft a From top to bottom, the primary distribution plate b, the scraper frame c, the material retaining plate e, the secondary distribution plate f, the material retaining plate e, the secondary distribution plate f, the scraper frame c, the material retaining plate e, The secondary distribution plate f, the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com