Comprehensive full-automatic range hood

A fully automatic, range hood technology, applied in the field of kitchen utensils, can solve the problems of secondary pollution, pollution of cooking utensils and food, and affecting the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

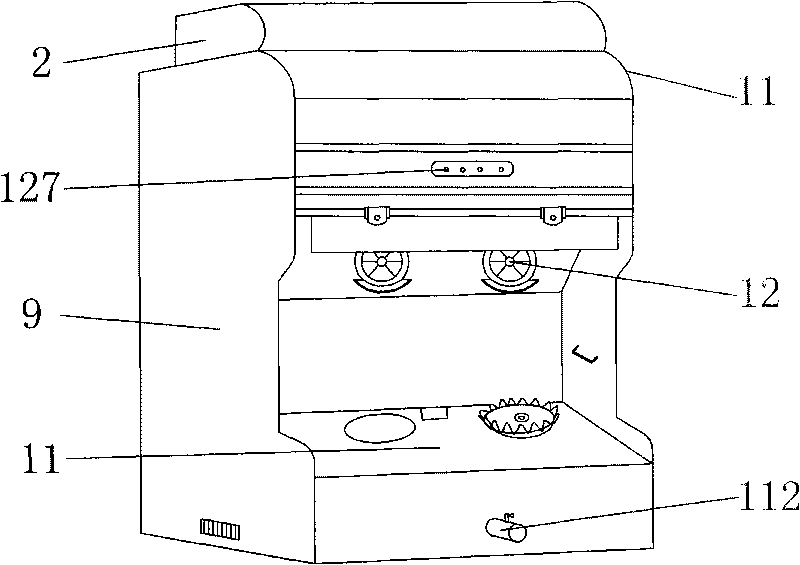

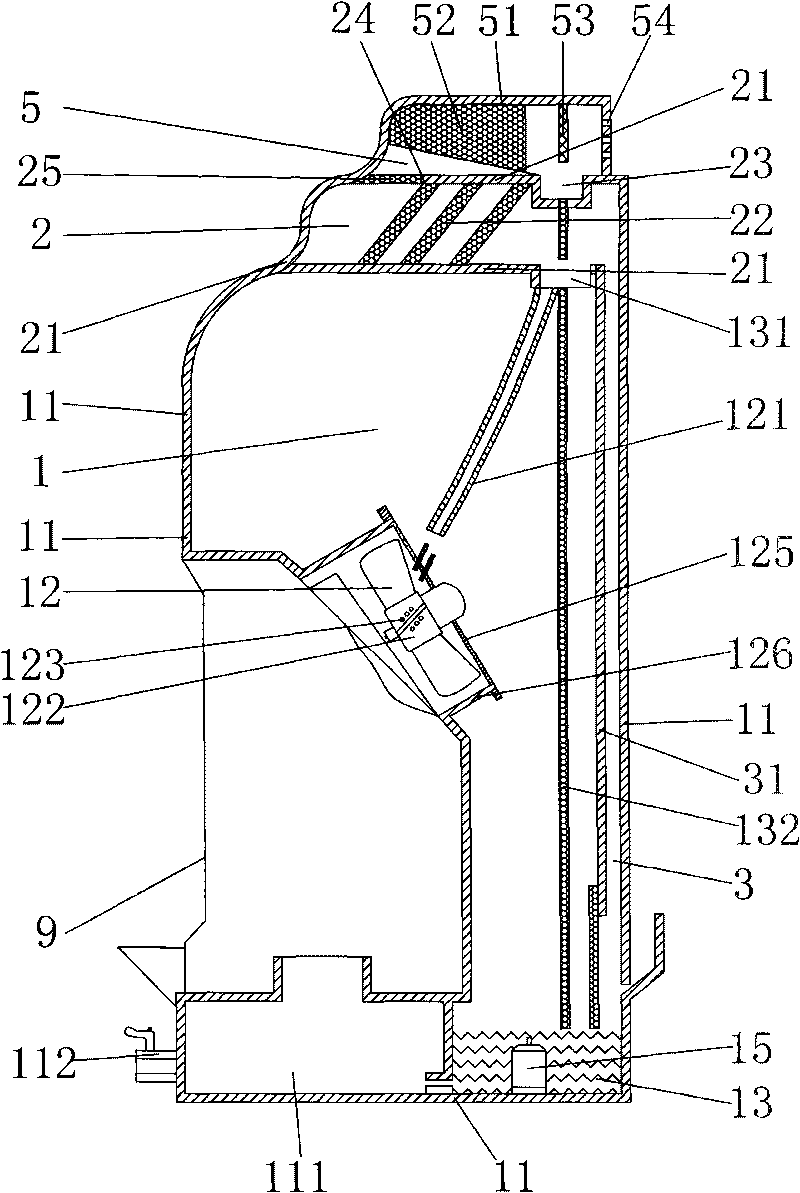

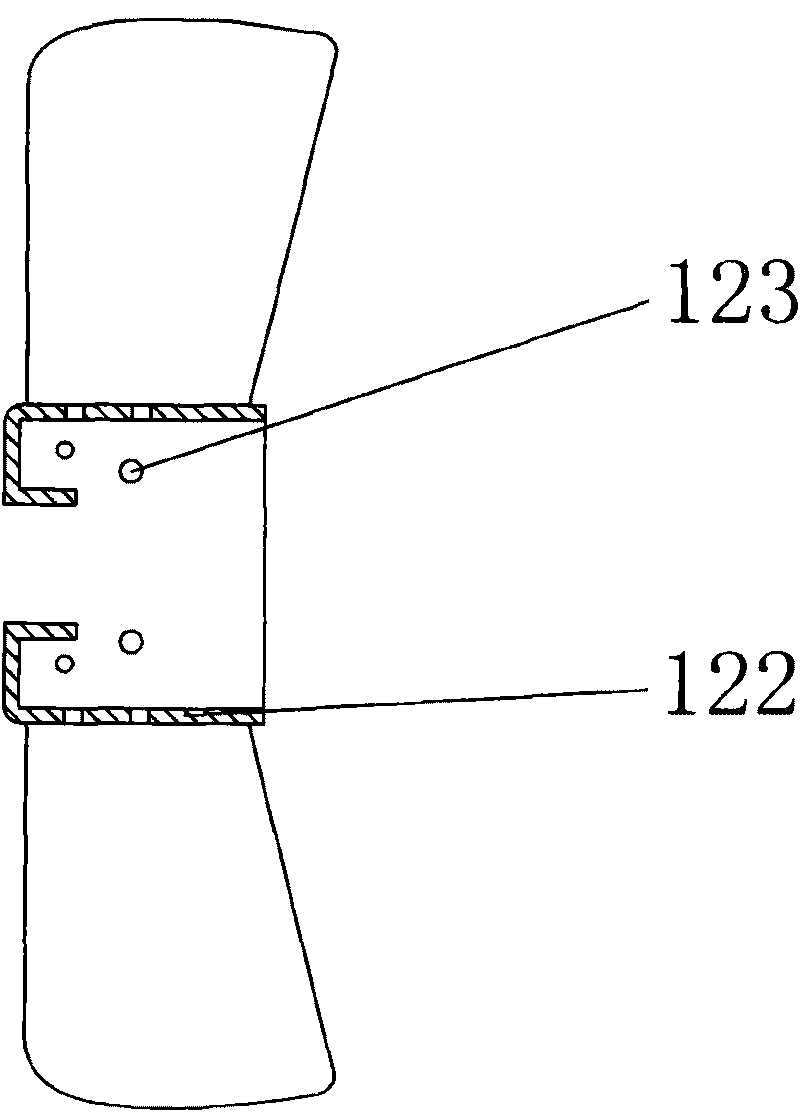

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a comprehensive automatic range hood includes a first clean room 1, a second clean room 2 above the first clean room 1, and a third clean room 5 above the second clean room 2. A clean room includes a housing 11, a fan 12 located at the front of the housing 11, a water storage tank 13 located at the inner bottom of the housing 11, a screen condensation water tank 131 located at the upper rear side of the housing, and a water storage tank located at the bottom of the housing. The water pump 15 in 13, the filter net 132 that is located at the screen condensed water tank 131 below, described fan 12 top is provided with self-controlled water pipe 121, and this self-controlled water pipe 121 links to each other with the screen condensed water tank 131 that is located at the screen condensed water tank 132 tops, so The fixed seat 122 of the fan is provided with an atomizing hole 123 to cooperate with the self-con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com