Method for embedding ground heat exchanger of ground source heat pump by high-pressure jet grouting

A technology of buried pipe heat exchanger and high-pressure rotary spraying, which is applied in heat pumps, lighting and heating equipment, and drilling with liquid/gas jets. The effects of environmental protection, leakage prevention, and flexible space layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] According to the design requirements of the heat exchanger of the ground source heat pump, the depth of the hole is determined according to the length of the heat exchanger.

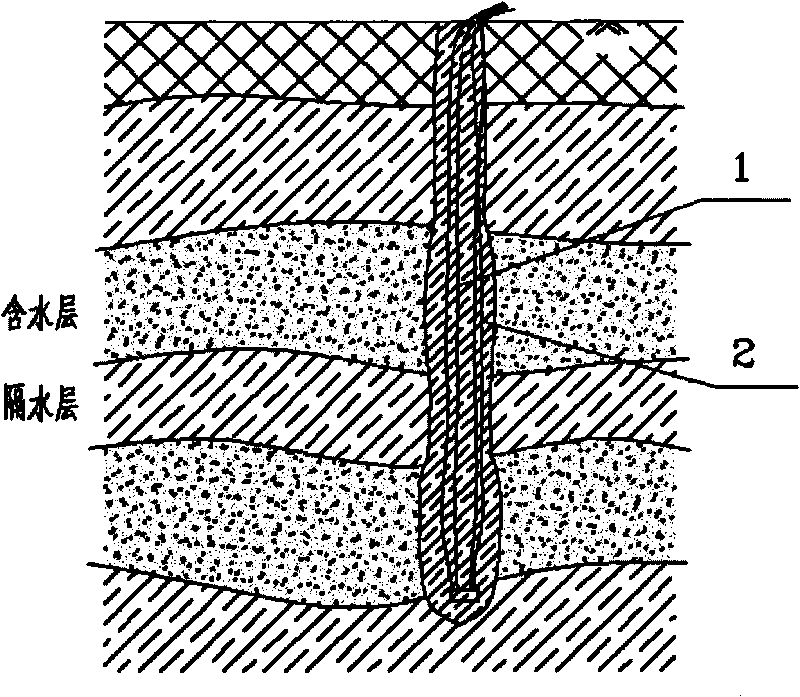

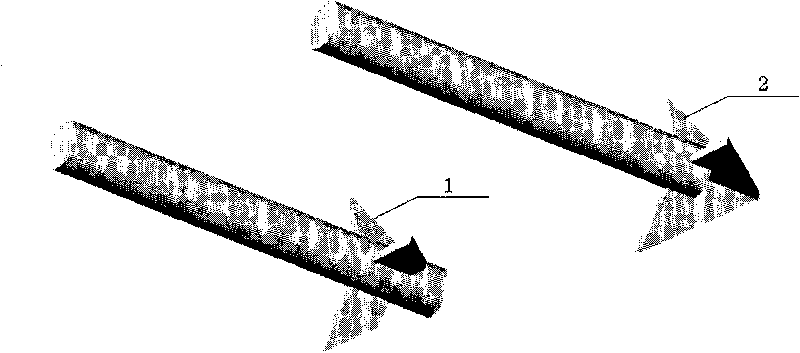

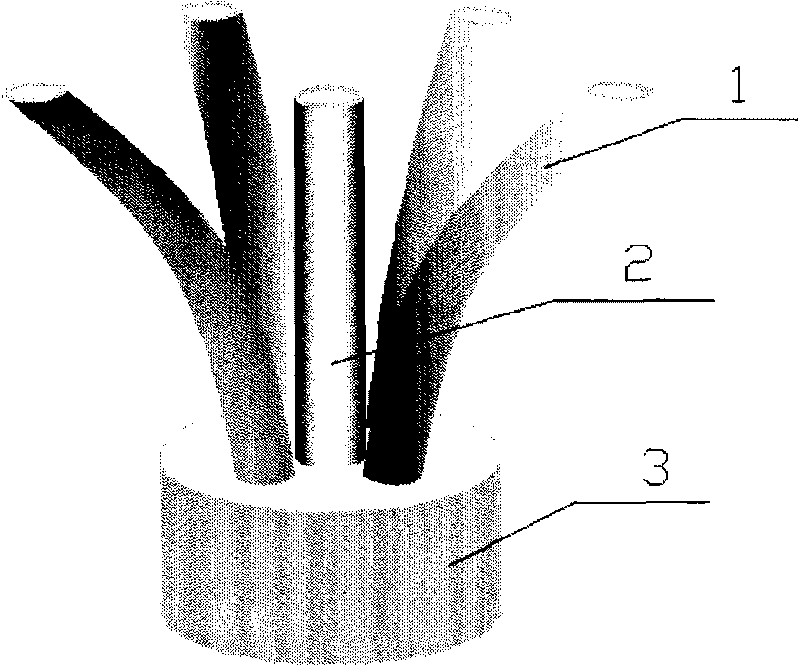

[0021] Such as figure 1 as shown, figure 1 Middle 1 is the reinforced body, which is in a fluid state when forming holes. Select the appropriate spraying pressure according to the formation conditions and use high-pressure rotary spraying to cut the soil to form holes or use high-pressure rotary spraying and spraying together. figure 2 The two kinds of stirring blades in the form of 1 and 2 are forced to stir together to form holes, and the holes are filled with mud, which becomes a reinforced solid after solidification. figure 1 Middle 2 is a buried pipe heat exchanger, which can be installed after forming a hole image 3 The special guide for middle 3 inserts the buried pipe heat exchanger into the hole for secondary forming, and it can also be brought into the hole for one-time forming while...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com