Glass fibre reinforced plastic capacitance multicore transformer bushing

A technology of transformer bushing and glass fiber reinforced plastic, applied in the direction of transformer/inductor coil/winding/connection, insulator, etc., can solve the problems of uneconomical, increase the volume of transformer, etc., achieve long life expectancy, ensure insulation performance, and high mechanical strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below in conjunction with the above-mentioned accompanying drawings.

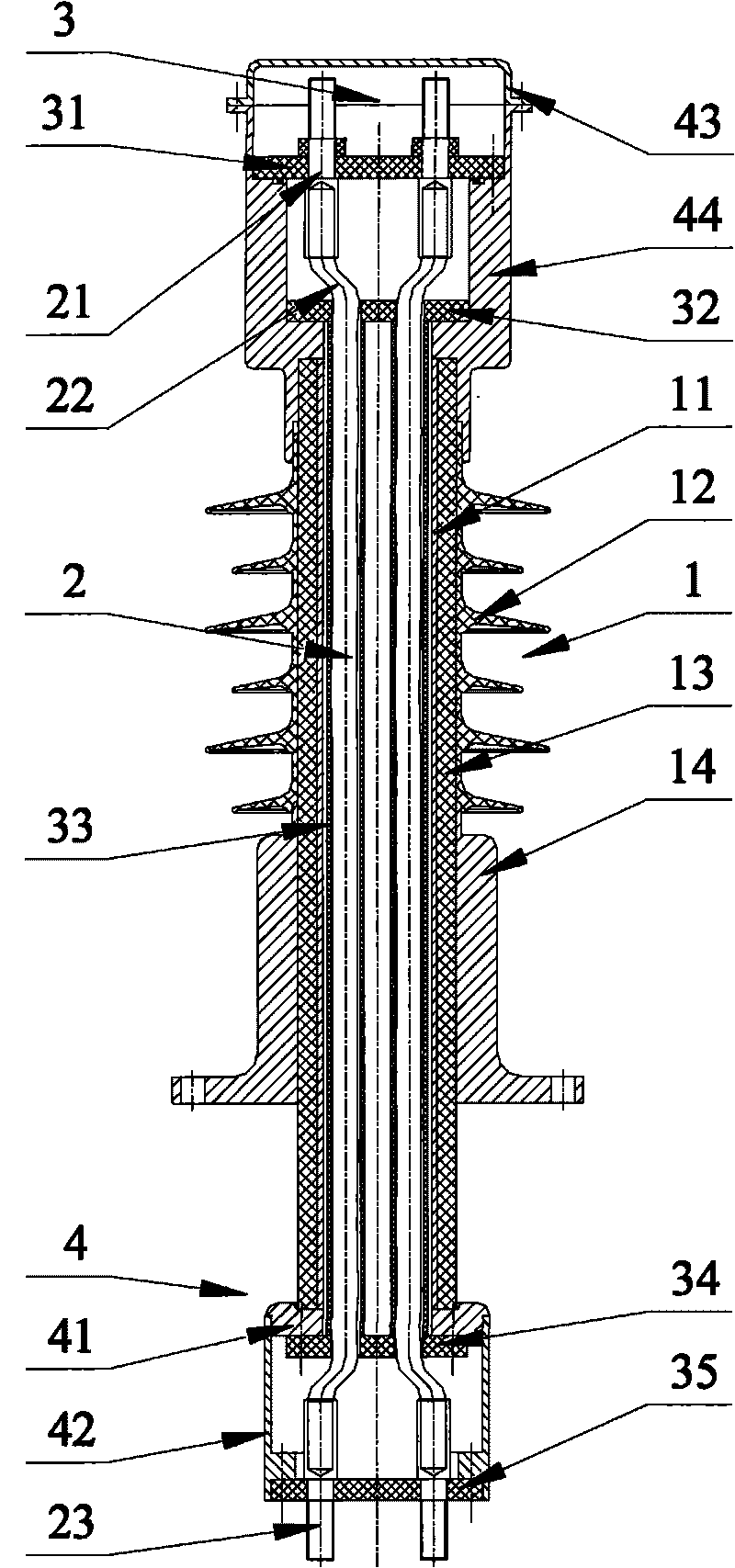

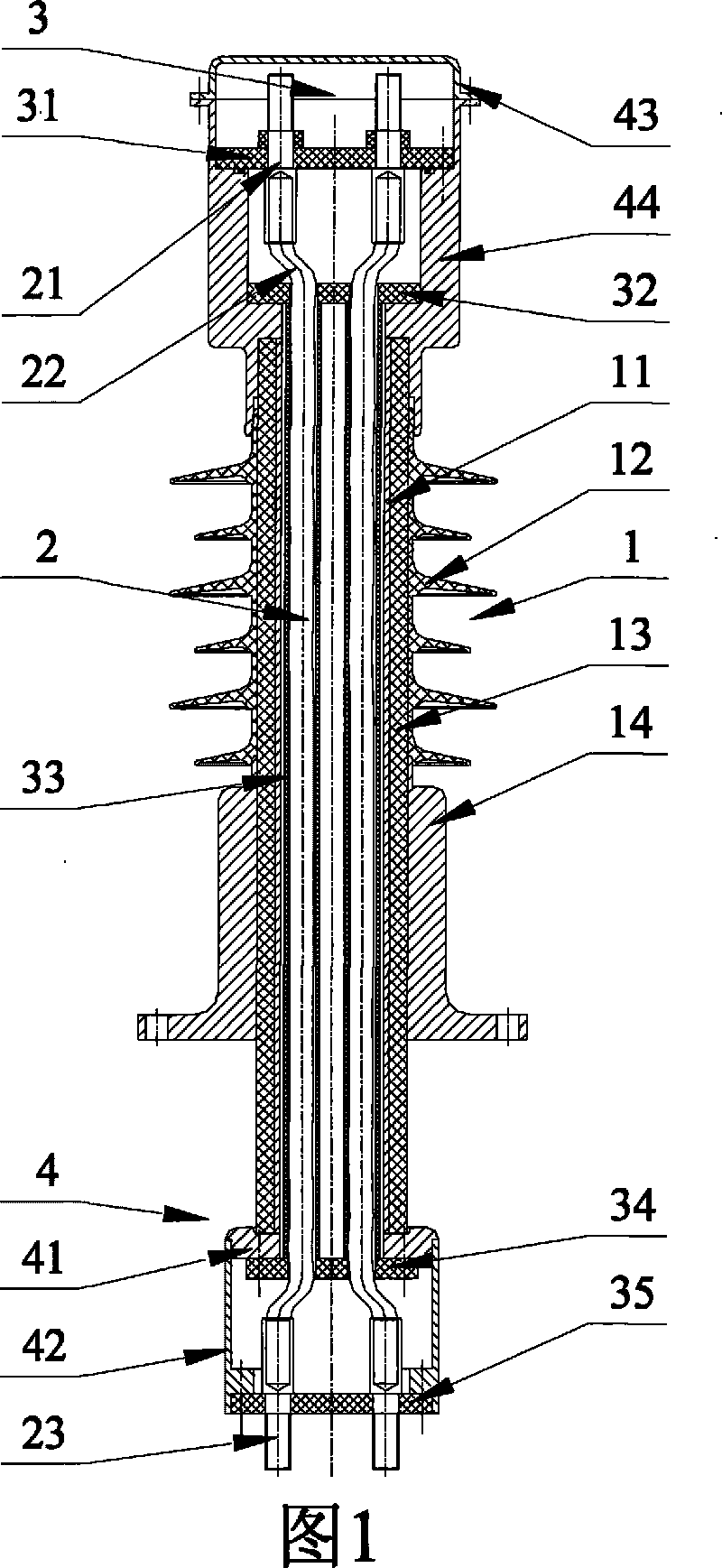

[0010] see figure 1 , which shows an embodiment of a glass fiber reinforced plastic capacitive multi-core transformer bushing according to the present invention, including a cable-through transformer bushing body (1), a cable-through lead wire (2), and an insulating bracket between the lead wires (3) and the pressure equalizing rainproof member (4) outside the oil in the oil.

[0011] Among them, the transformer bushing body (1) has a central metal tube (11), a silicone rubber shed (12), a fiberglass capacitor core (13) and a flange member (14), and the silicone rubber shed (12) is the sleeve External insulation, the flange member (14) is the connection part between the bushing and the transformer.

[0012] Wherein the cable lead wire (2) has a plurality of mutually insulated copper cables (22) and outdoor lead terminals (21) and oil end terminals (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com