A hdpe self-tensioning flat-bottom lifting type current-resistant cage device

A lifting and net cage technology, applied in fish farming, application, climate change adaptation, etc., to achieve the effect of large breeding platform, avoiding typhoon and red tide attack, simple and easy structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

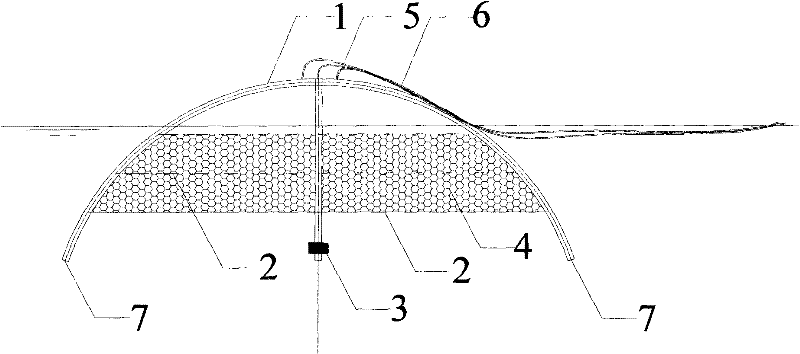

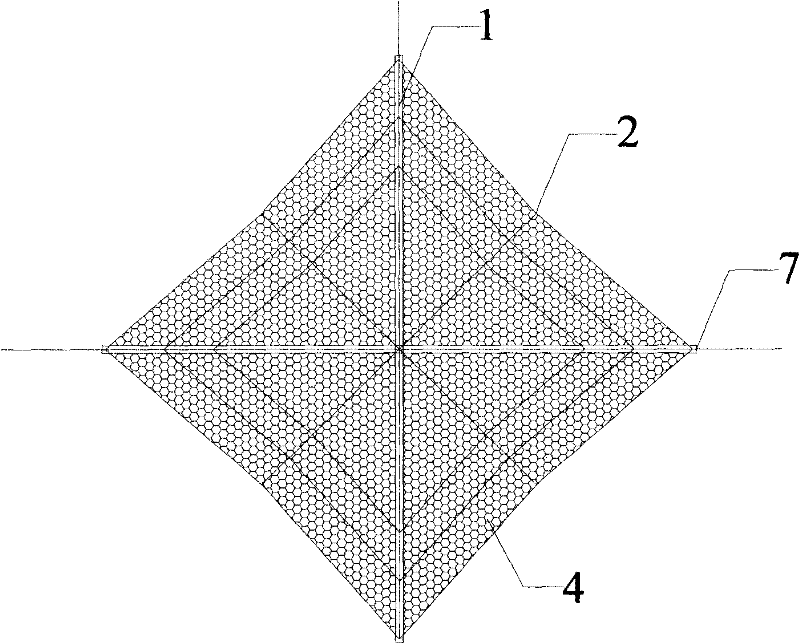

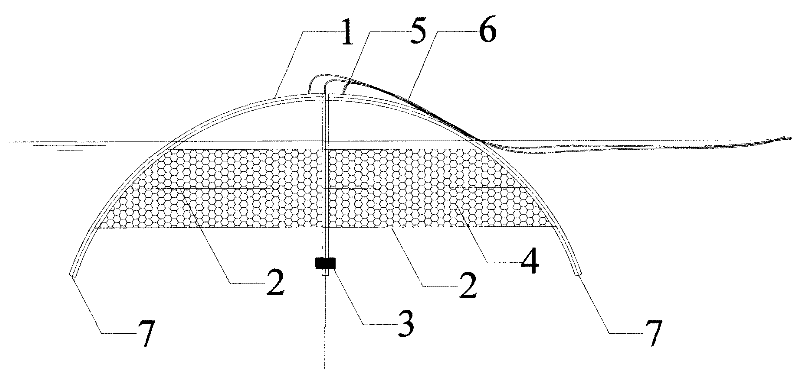

[0015] see Figure 1-2 , the specific embodiment adopts the following technical solutions: it is a spherical net cage main frame 1 constructed by HDPE pipes, a high-strength fishing pull-joint rope 2, a central gravity plummet self-balancing device 3, net clothing 4, and HDPE pipe row Inflatable port 5, high-strength exhaust and inflation hose 6, HDPE inlet and outlet pipe 7; HDPE pipe spherical main frame 1, high-strength fishing rope 2, center gravity pendulum self-balancing device 3, net 4 to form a net The main body of the box is to weld the HDPE pipe with the tee and four-way connecting pipe fittings, and use the self-tension of the elastic bending of the HDPE pipe to form a spherical HDPE pipe spherical main frame 1 and the bottom of the box by pulling the high-strength fishing rope 2. Platform; the pendent rope of the central gravity pendent self-balancing device 3 is suspended from the center of the spherical surface, and passes through the crossing points of the ropes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com