Visible light catalyst BiNbO4, preparation method thereof and application thereof

A catalyst and visible light technology, applied in the field of photocatalysis, can solve the problems of insufficient research on photocatalytic properties, and achieve the effects of simple synthesis method, wide application range and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

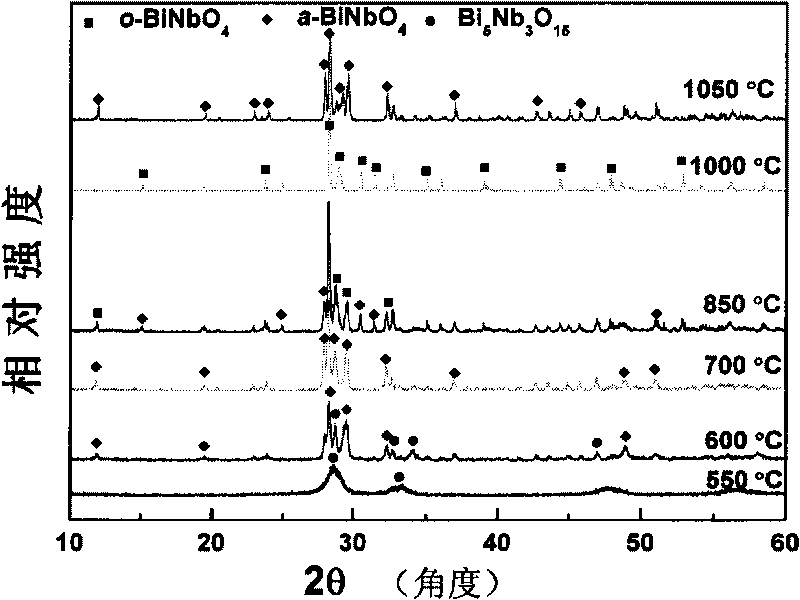

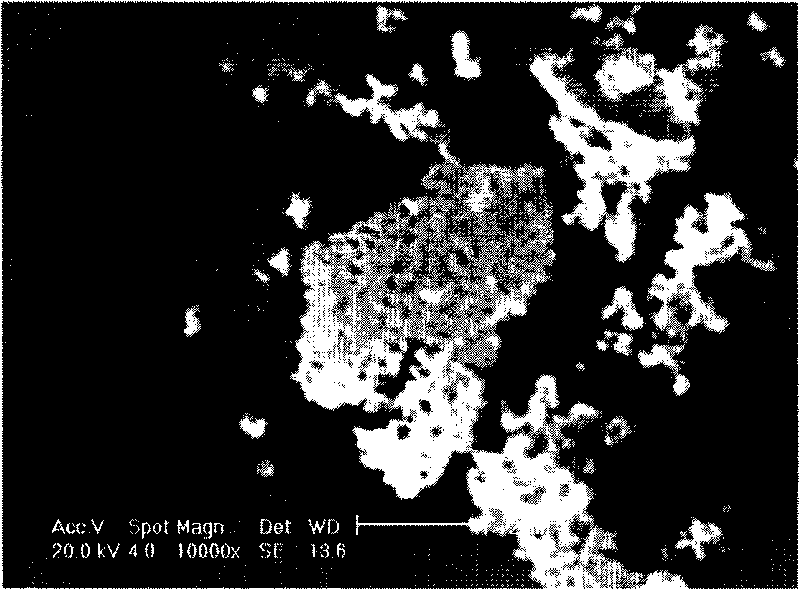

[0020] Get 7.45g niobium precursor (134.2μmol / g) in 50ml beaker, 0.51g bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) dissolved therein, the mixed solution was stirred at 60°C, and ammonia water was added to adjust the pH value to 7-8, and the solution was a colorless transparent liquid. After the solution is prepared, it is baked in an oven at 180° C. for 4 hours to obtain a yellow-brown precursor powder. Then calcined in a muffle furnace at 700 °C for 3 hours to obtain white BiNbO 4 Powder, the specific surface area of the product is about 10.44m 2 / g. figure 1 is BiNbO 4 X-ray diffraction pattern of the powder. Figure 2(a) BiNbO annealed at 700°C for 3 hours 4 SEM topography photos of the powder; Figure 2(b) annealed at 1000°C for 3 hours; Figure 2(c) annealed at 1050°C for 3 hours.

[0021] The white powder (1g / L) was used to degrade a 10mg / L methyl violet solution, and after being ultrasonically dispersed in an ultrasonic bath for 10 minutes at room temperat...

Embodiment 2

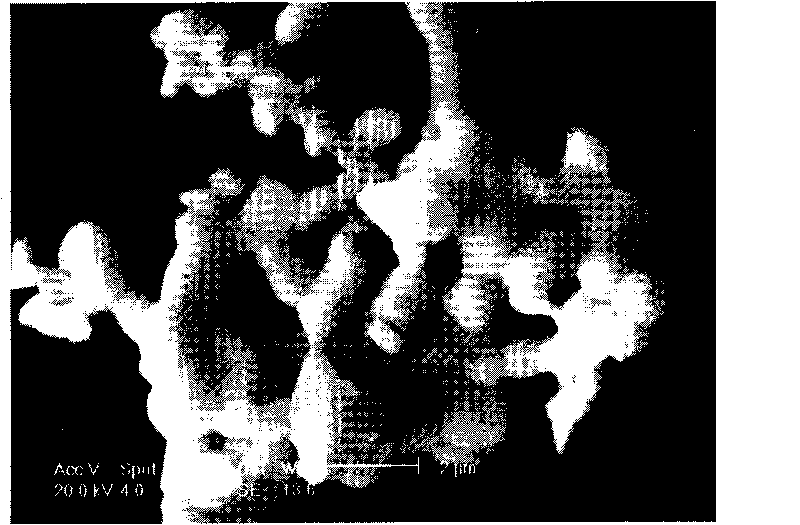

[0023] Other conditions are the same as in Example 1. After annealing at 1000° C. for 3 hours, the final product is a white powder. Use the obtained powder (1g / L) to degrade 10mg / L methyl violet solution, ultrasonically disperse at room temperature for 10 minutes, react under visible light for 2.5 hours, the degradation rate reaches 100%, and the specific surface area of the product is about 11.47m 2 / g; Figure 2(b) is BiNbO annealed at 1000°C for 3 hours 4 SEM photo of the powder.

Embodiment 3

[0025] Other conditions are the same as in Example 1. After annealing at 1050° C. for 3 hours, the final product is white powder. Use the obtained powder (1g / L) to degrade 10mg / L methyl violet solution, ultrasonically disperse at room temperature for 10 minutes, react under visible light for 2.5 hours, the degradation rate reaches 100%, and the specific surface area of the product is about 7.86m 2 / g. Figure 2(c) is BiNbO annealed at 1050°C for 3 hours 4 SEM photo of the powder.

[0026] image 3 are BiNbO prepared at different annealing temperatures 4 The visible light degradation curve of methyl violet, the catalyst amount is 1g / L, and the sampling interval is 0.5h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com