Grinding system used for extracting vanadium from stone coal

A technology of grinding and stone coal, which is applied in the field of grinding system for extracting vanadium from stone coal, can solve the problems that enterprises cannot reduce costs and increase efficiency, cannot use hot waste gas heat energy, and fine-grained products are difficult to effectively recycle, and achieve improved Grinding efficiency, high waste heat utilization rate, and the effect of improving dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment, not limitation to protection scope:

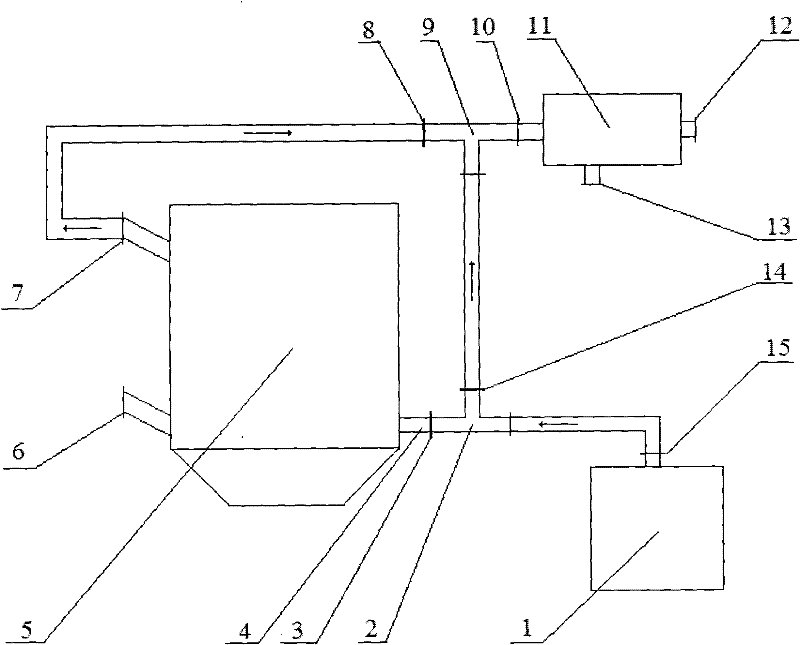

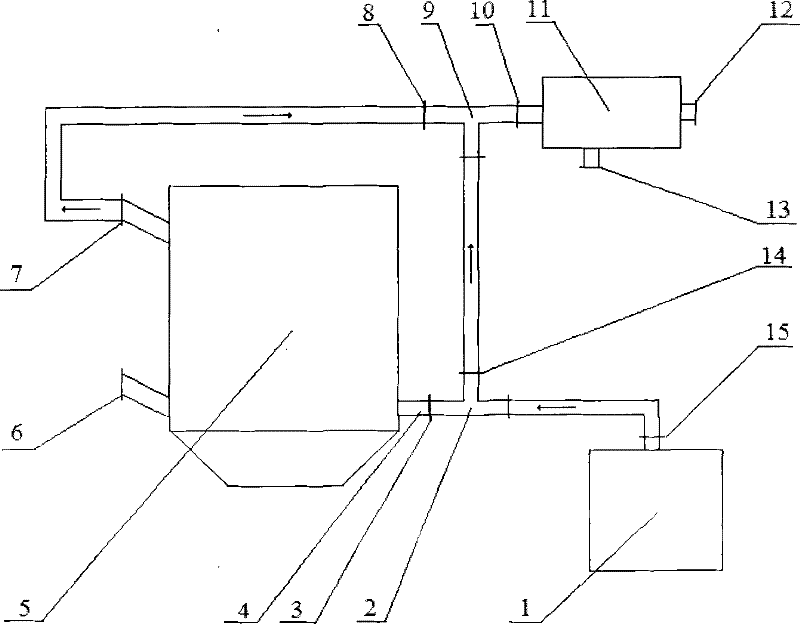

[0012] A grinding system for vanadium extraction from stone coal, such as figure 1 As shown, it consists of a vertical mill 5, a combustion furnace 1 and a bag filter 11. The air inlet 4 of the vertical mill 5 communicates with the hot gas outlet 15 of the combustion furnace 1 through the first gas valve 3, the first three-way pipe 2 and the pipeline, and the discharge gas port 7 of the vertical mill 5 passes through the pipeline, the third gas valve 8 and the second three-way pipe 9 communicate with the airflow inlet 10 of the bag filter 11, and the first three-way pipe 2 communicates with the second three-way pipe 9 through the second air valve 14 and the pipeline.

[0013] The operation process of this system is as follows: in the process of extracting vanadium from stone coal, the raw materials to be ground en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com