Air intake and discharge grille for special vehicle

A special vehicle and grille technology, applied in the direction of radiators, etc., can solve the problems of large aerodynamic resistance, heavy weight, complex processing, etc., and achieve the effect of improving capacity, low processing cost, and reducing flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

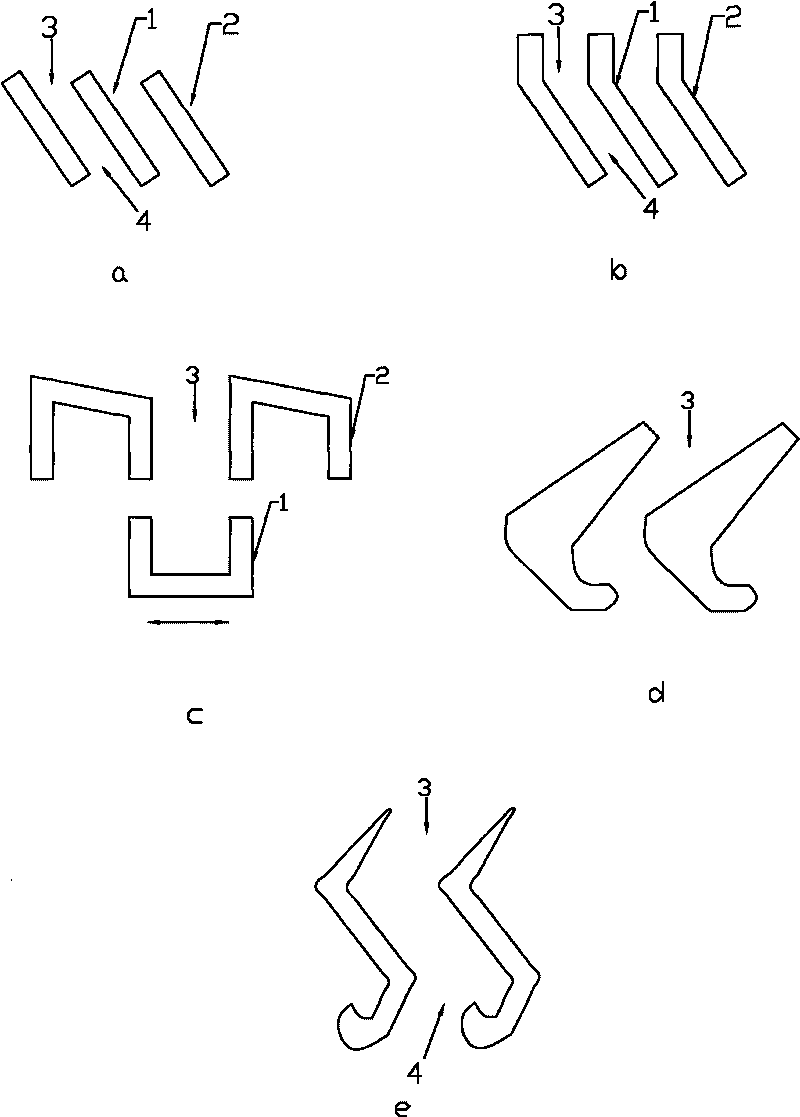

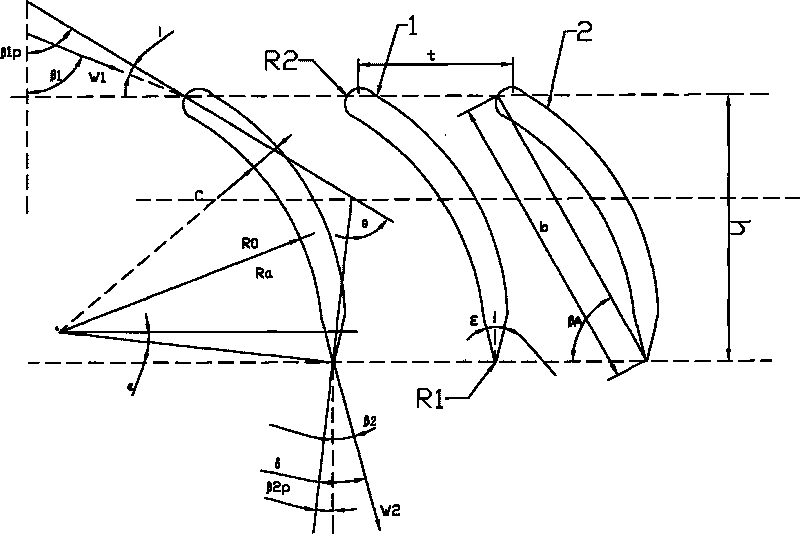

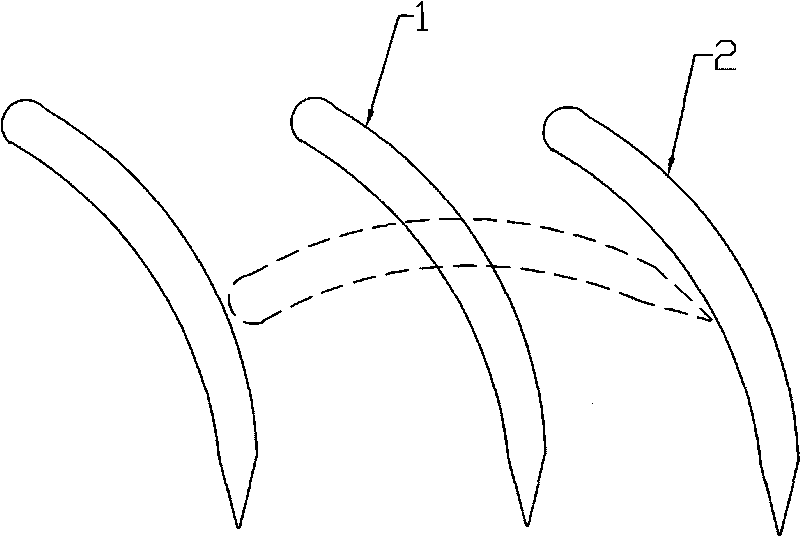

[0023] Such as figure 2 As shown, the single arc curved plate intake and exhaust grille of the present invention includes a moving blade 1 and a stationary blade 2, and the blades are mainly composed of four arcs and two straight lines. The positive airflow 3 and the reverse airflow 4 enter and exit from both ends of the blade, such as image 3 As shown, the moving blade can rotate when needed, and is stuck between two stationary blades to enhance the protection function. The specific design process of the blade is as follows:

[0024] Known: the cooling air volume through the air intake grille is 7.87m 3 / s, the air intake grille flow area is about 1.2419m 2 , the thickness of the grid blades is 6mm, and the thickness of the grid structure is 50mm, then:

[0025] (1) Take the average speed of the vehicle as u1=40km / h=11.11m / s, and the vertical inlet speed above the air intake grille V 1 = 7.87 1.2419 = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com