Flexible microgripper through topological optimization

A technology of topology optimization and micro-clamps, which is applied in the direction of micro-structure technology, micro-manipulators, micro-structure devices, etc., can solve the problems of large size of micro-clamps and different shapes of clamp bodies, and achieve fast response, simple control, and economical energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

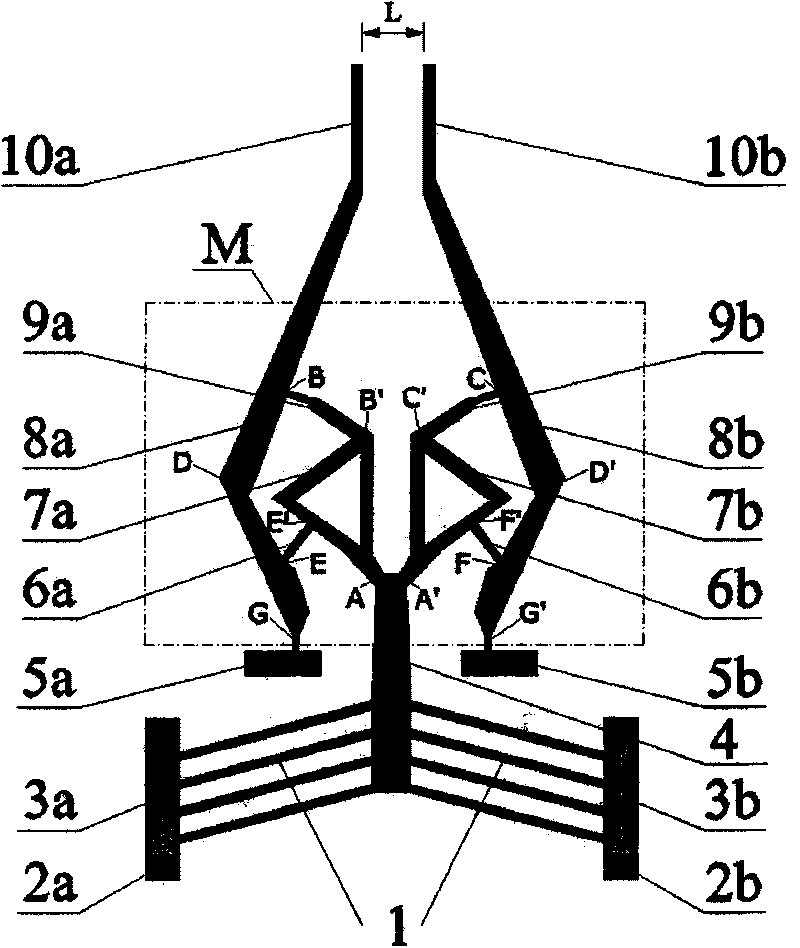

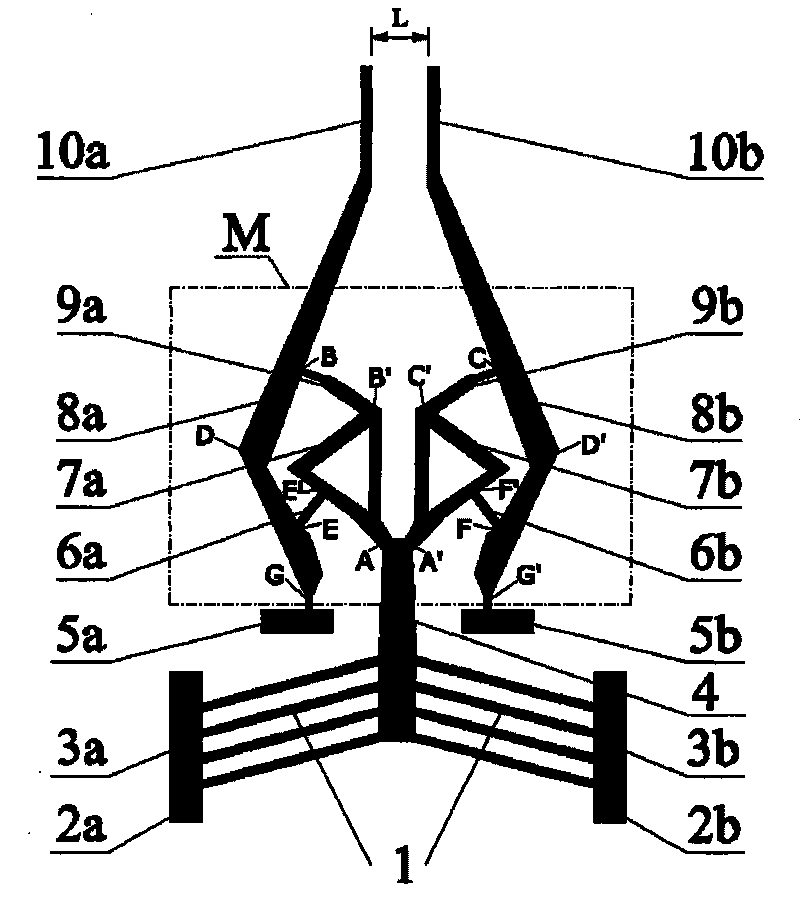

[0012] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings. Such as figure 2 Shown is the left part of the enlarged part M of the forceps body, and the right part is symmetrical to it. Then, CAD and finite element analysis software were used to geometrically reconstruct the topological configuration of the topology optimization design, modify the single-point hinge to a flexible hinge to appropriately increase the stiffness, and determine the shape of the micro-clamp according to the specific situation. The topology optimization design method gets rid of the empirical design idea of the traditional pseudo-rigid body method, but seeks the best material distribution method from the perspective of the elastic body material itself to meet the design idea of the fully flexible mechanism.

[0013] as attached figure 1 As shown, when the drive is applied to the micro-clamp: af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com