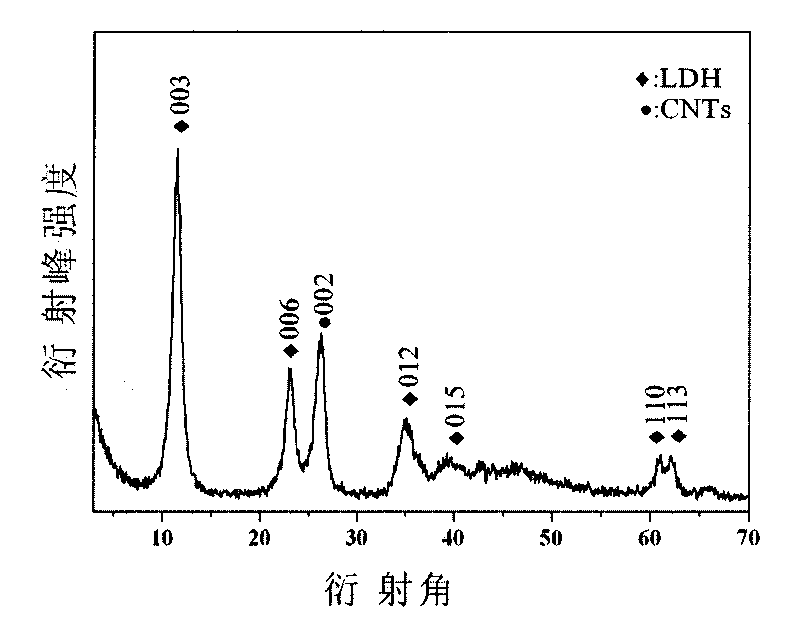

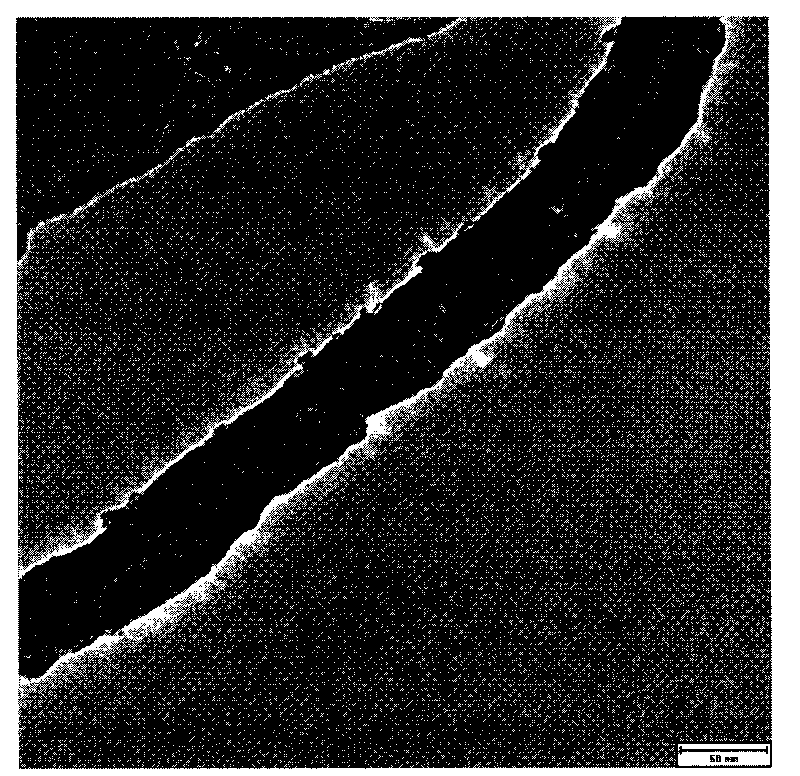

NiAl-laminated type bimetal hydroxide/carbon nano-tube compound electrode as well as preparation method and application thereof

A layered bimetallic and carbon nanotube technology, applied in the direction of material electrochemical variables, material analysis by electromagnetic means, instruments, etc., can solve the problems of reduced active sites, small specific surface area, poor dispersion, etc., to improve dispersion , The preparation method is simple, the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A. Weigh 2.1810g of Ni(NO 3 ) 2 ·6H 2 O and 0.9378g of Al(NO 3 ) 3 9H 2 O was dissolved in deionized water to prepare Ni(NO 3 ) 2 and Al(NO 3 ) 3 mixed salt, where Ni(NO 3 ) 2 The concentration is 0.15mol / L, Al(NO 3 ) 3 The concentration is 0.05mol / L; NaOH and Na 2 CO 3 Dissolve in deionized water to prepare NaOH and Na 2 CO 3 Mixed salt, wherein the concentration of NaOH is 0.32mol / L, Na 2 CO 3 The concentration is 0.10mol / L; another NaOH supplement with a concentration of 0.32mol / L is prepared with deionized water;

[0025] B. Take 0.5000g of acid-treated carbon nanotubes and 50ml of mixed alkali and add them to the reaction vessel at the same time, so that the concentration of carbon nanotubes in the mixture is 10mg / ml, ultrasonically disperse for 30min, take 50ml of mixed salt and add it dropwise to the reaction vessel Add dropwise NaOH to supplement, control the pH=10.5, and then ultrasonically disperse for 30 minutes until the addition of the mix...

Embodiment 2

[0029] A. prepare several of same concentration and volume with embodiment 1;

[0030] B. Take acid-treated carbon nanotubes and 50ml of mixed alkali and add them to the reaction vessel, wherein the concentration of carbon nanotubes in the medium is 15mg / ml. After ultrasonic dispersion for 30min, add 50ml of the prepared mixed salt dropwise to the reaction vessel In the container, add NaOH dropwise to supplement, control the pH=10.5, and then ultrasonically disperse for 30 minutes until the addition of the mixed salt is completed. After the end, wash with deionized water until neutral, and finally dry the filter cake in an oven at 60° C. for 12 hours to obtain a NiAl-layered double metal hydroxide / carbon nanotube composite.

[0031] C. Take 0.20 g of the compound obtained above and add it into 10 ml of ultrapure water to prepare a solution with a solid content of the compound of 20 mg / ml. Stir magnetically for 3 hours at room temperature, press 0.35 μl / mm 2 The amount is dro...

Embodiment 3

[0033] A. Weigh 2.9080g of Ni(NO 3 ) 2 ·6H 2 O and 1.8756g of Al(NO 3 ) 3 9H 2 O was dissolved in deionized water to prepare Ni(NO 3 ) 2 and Al(NO 3 ) 3 mixed salt, where Ni(NO 3 ) 2 The concentration is 0.20mol / L, Al(NO 3 ) 3 The concentration is 0.10mol / L; Weigh 0.9600g of NaOH and 1.0598g of NaOH 2 CO 3 Dissolve in deionized water to prepare NaOH and Na 2 CO 3 Mixed salt, wherein the concentration of NaOH is 0.48mol / L, Na 2 CO 3 The concentration is 0.20mol / L; another NaOH supplement with a concentration of 0.32mol / L is prepared with deionized water;

[0034] B. Add acid-treated carbon nanotubes and 50ml of mixed alkali into the reaction vessel, wherein the concentration of carbon nanotubes in the medium is 10mg / ml, and after ultrasonic dispersion for 20min, add 50ml of the prepared mixed salt to the reaction vessel dropwise In the container, add NaOH dropwise to supplement, control the pH=9, until the mixed salt is added dropwise, then ultrasonically disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com