Image plane focusing mechanism used for push-broom type aero remote sensor

An aerial remote sensing, push-broom technology, applied in the field of aerial photography, to achieve the effect of high motion and position accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

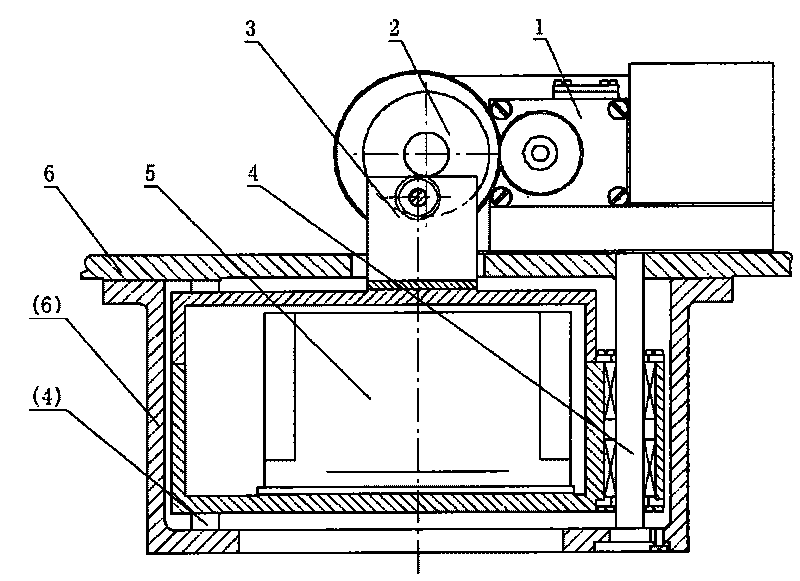

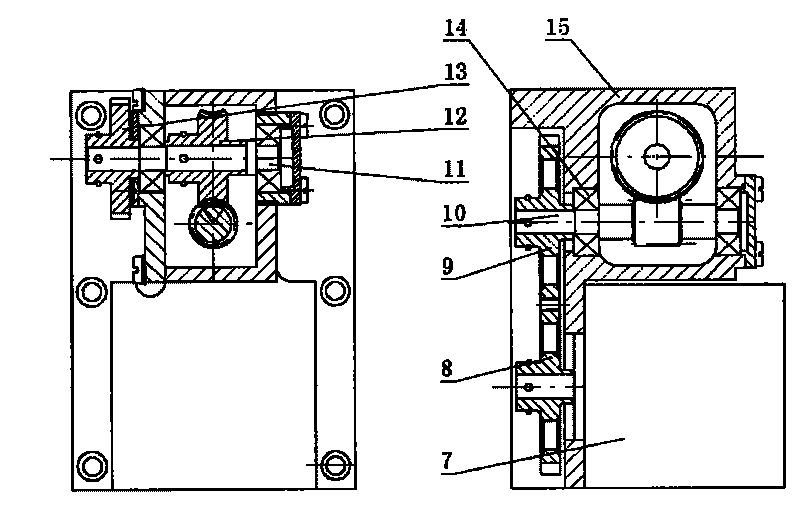

[0018] Examples of the present invention are figure 1 Including: worm gear box assembly 1, cam assembly 2, roller assembly 3, precision linear guide rail 4, focal plane assembly 5 and remote sensor housing 6, etc.

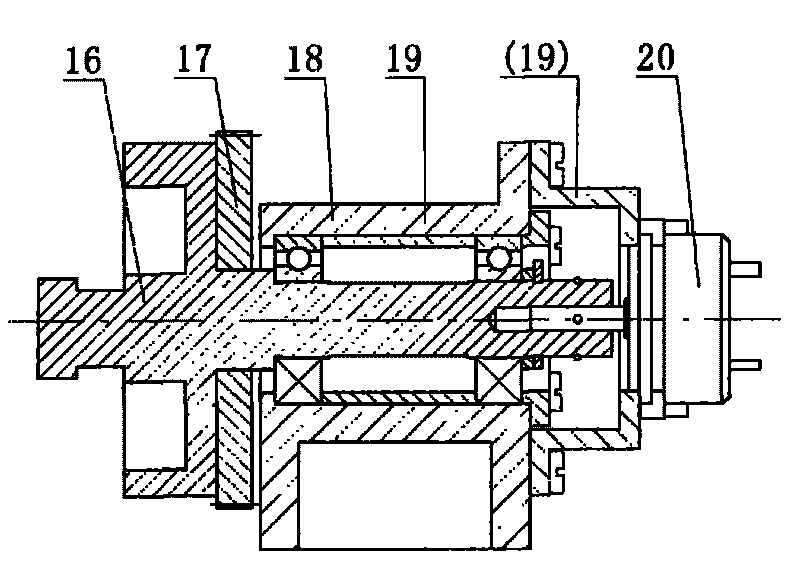

[0019] The worm gear box assembly 1 and the cam assembly 2 are mounted on the remote sensor housing 6 and connected with the cam gear 17 through the worm gear 13 . The precision linear guide rail 4 is installed on the remote sensor housing 6, the focal plane assembly 5 is installed on the precision linear guide rail 4 through the linear bearing 28, the roller assembly 3 is installed on the focal plane assembly 5, and the large roller 23 and the small roller 24 links to each other with hyperbolic cam 16.

[0020] In order to ensure the motion accuracy of the focal plane assembly 5, the material of the precision linear guide 4 requires good wear resistance and high hardness, so GCr15 bearing steel or 9Cr18 stainless steel with good wear resistance is used, and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com