Production technology of rice noodles and production line thereof

A production process and production line technology, which is applied in the production process and production line of Yunnan bridge rice noodles, can solve the problems of poor quality of bridge rice noodles, difficult water pollution treatment, large manpower demand, etc., and achieve high production efficiency and cooling speed Fast, high ripening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

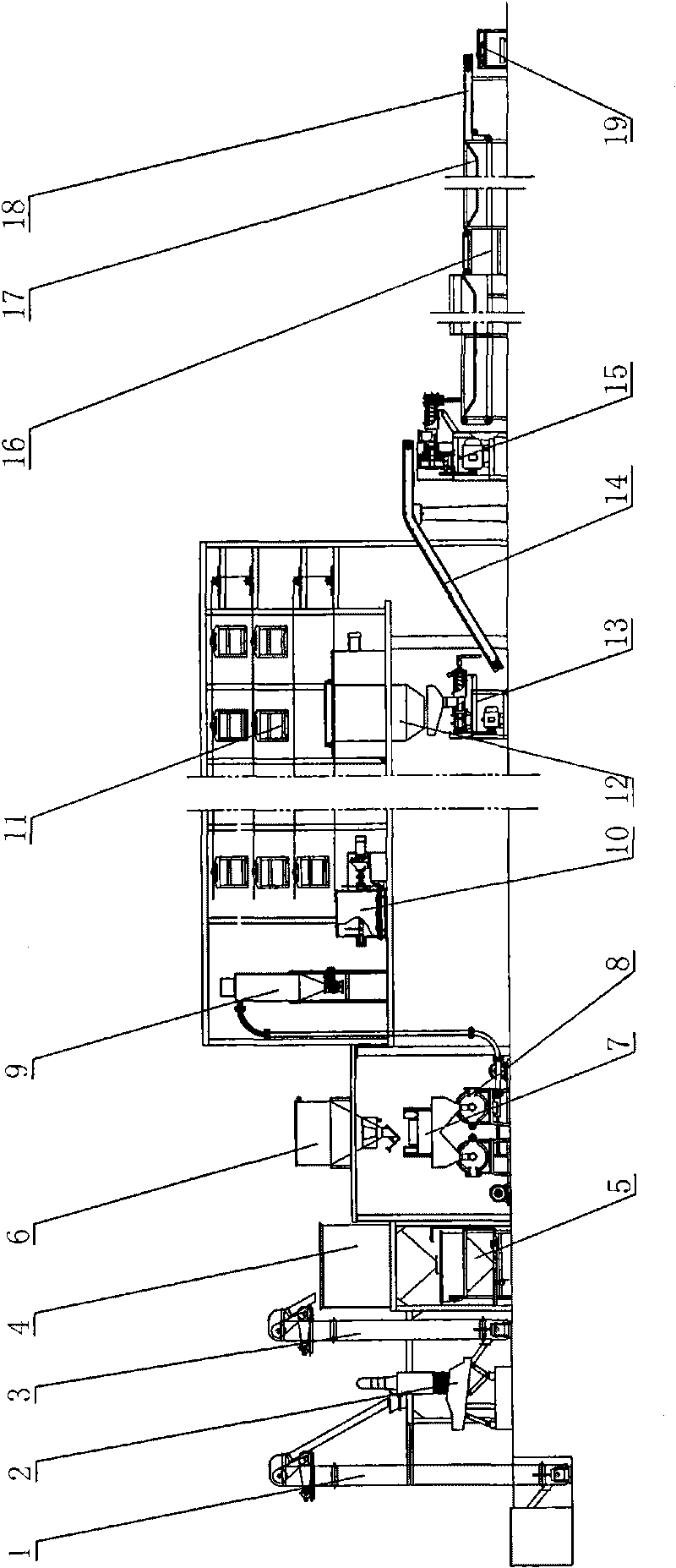

[0038] like figure 1 The bridge-crossing rice noodle production line shown includes primary elevator 1, air jet rice mill 20, specific gravity desander 2, secondary elevator 3, rice storage tank 4, jet rice washing machine 5, water rice separation Machine 6, Vibrating Conveyor 7, Micro Powder Crusher 8, Rice Noodle Air Conveyor 9, Powder Mixing Machine 10, Delay Conveyor 11, Mixer 12, Self-cooking Machine 13, Conveyor 14, Wire Extruder 15, Boiler Machine 16, water cooler 17, swing stacker 18 and electronic scale 19.

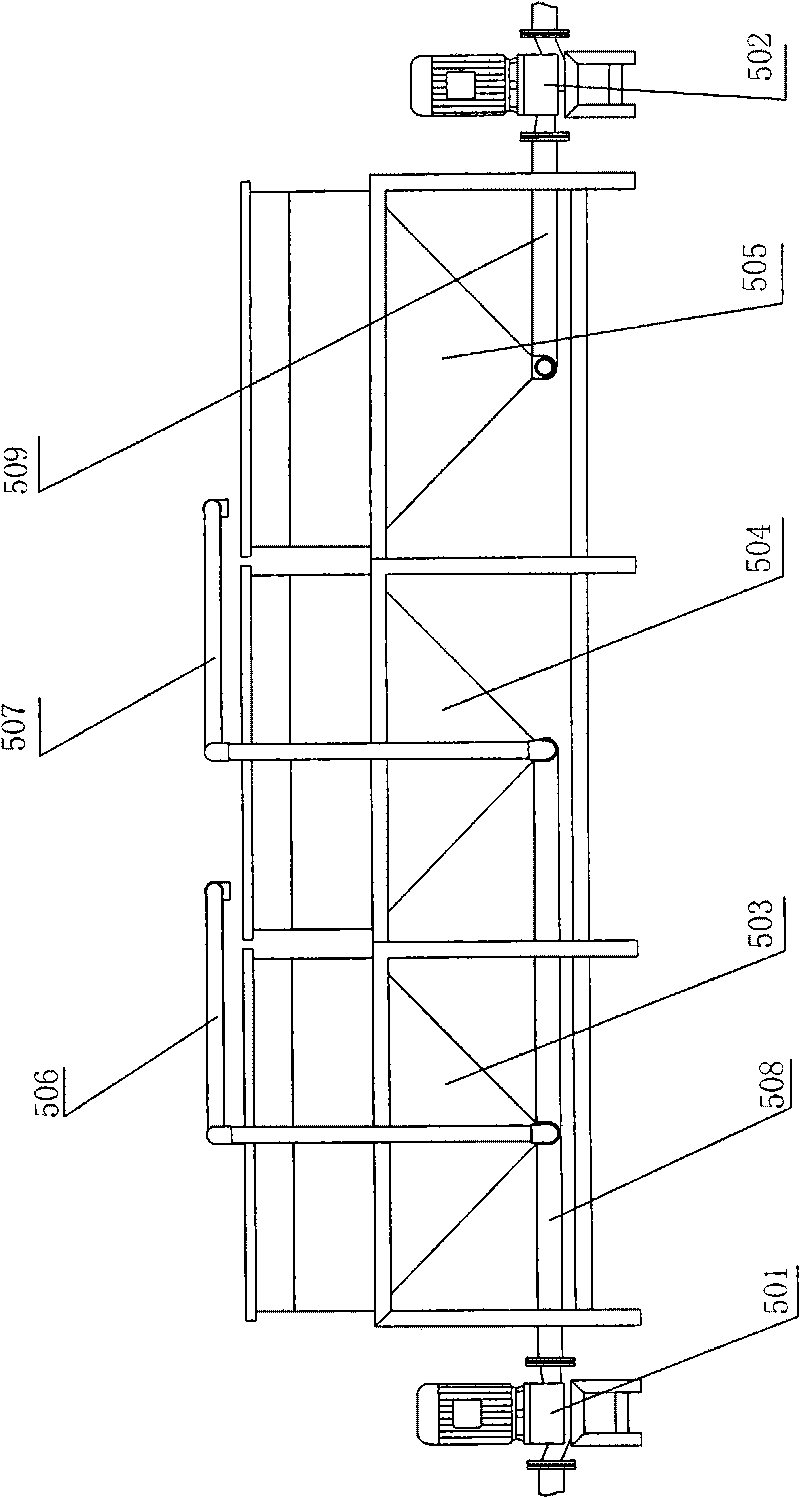

[0039] like figure 2 As shown, the jet rice washing machine includes a water supply motor (not marked), a pump water motor 501, a rice pumping motor 502, a first rice washing tank 503, a second rice washing tank 504, and a third rice washing tank 505; There is a pipeline connection between the tanks, the rice washing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com