Production method of heat transfer film imitating solid wood

A thermal transfer film and production method technology, applied to the device for coating liquid on the surface, the process for producing decorative surface effects, decorative arts, etc., can solve the problems of low yield, difficult transfer, deformation of carrier film, etc. problem, to achieve the effect of low curing temperature and difficult printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

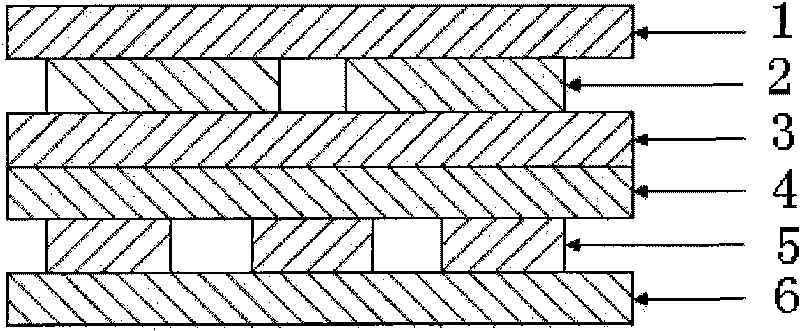

[0026] Such as figure 1 Shown, a kind of production method of imitation solid wood thermal transfer film adopts thick 25 μ biaxially stretched polyester film (BOPET) matte film as carrier film 1, and adopts the double group of polyurethane resin and isocyanate to form on this carrier film Resin is used for local coating treatment to obtain partial treatment layer 2, and a solid wood pore pattern is formed on carrier film 1; then solid wood pore effect is formed after curing in an oven at 70°C for 36 hours, and then coating release layer 3 and protective layer 4 are released. The material of the type layer and the protective layer is acrylic resin, and then the pattern information layer 5 and the following layer 6 are printed, and the material of the following layer 6 is acrylic resin, and finally an imitation solid wood transfer film is formed.

Embodiment 2

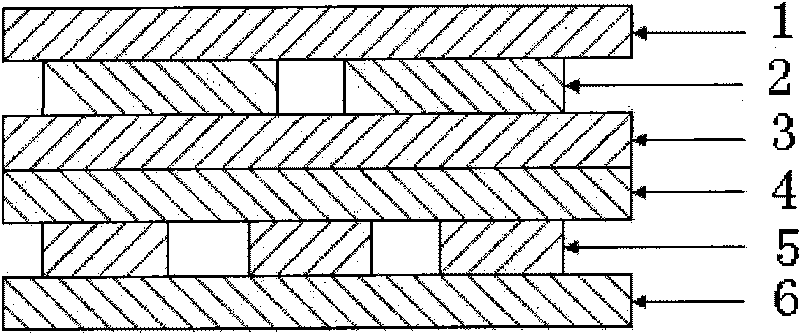

[0028] A method for producing imitation solid wood thermal transfer film, the method comprising the following steps:

[0029] (1) A biaxially stretched polyester film (BOPET) bright film with a thickness of 15 μ is used as a carrier film, and a two-component resin of polyurethane and polyester is used for partial coating on the carrier film to obtain a partial treatment layer. A solid wood air hole pattern is formed on the film;

[0030] (2) The film obtained in step (1) is placed in a 60°C oven for curing, the curing time is 48 hours, and a solid wood pore pattern is formed on the carrier film;

[0031] (3) on the partial treatment layer of the film that step (2) obtains, coat release layer and protective layer successively, release layer is polyamide resin, and protective layer is polyester resin;

[0032] (4) Print the information layer graphic layer on one side of the protective layer, such as solid wood pattern;

Embodiment 3

[0035] A method for producing imitation solid wood thermal transfer film, the method comprising the following steps:

[0036] (1) A biaxially stretched polyester film (BOPET) bright film with a thickness of 30 μ is used as the carrier film, and a two-component resin of vinyl acetate resin and acid ketone resin is used for partial coating on the carrier film to obtain a partial treatment layer , forming a solid wood pore pattern on the carrier film;

[0037] (2) Place the film obtained in step (1) in an oven at 80° C. for curing, and the curing time is 24 hours to form a solid wood pore pattern on the carrier film;

[0038] (3) on the partial treatment layer of the film that step (2) obtains, coat release layer and protective layer successively, release layer is vinyl chloride resin, and protective layer is polyurethane resin;

[0039] (4) Print the information layer graphic layer on one side of the protective layer, such as solid wood pattern;

[0040] (5) Coating an adhesiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com