Continuous hydrogenation reaction device

A hydrogenation reaction, multiphase reactor technology, applied in feeding devices, chemical/physical/physical-chemical stationary reactors, chemical instruments and methods, etc., can solve the problems of easily broken catalysts, inconvenient operation, poor stability, etc. Achieve the effect of high catalyst recovery rate, reduced energy consumption and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

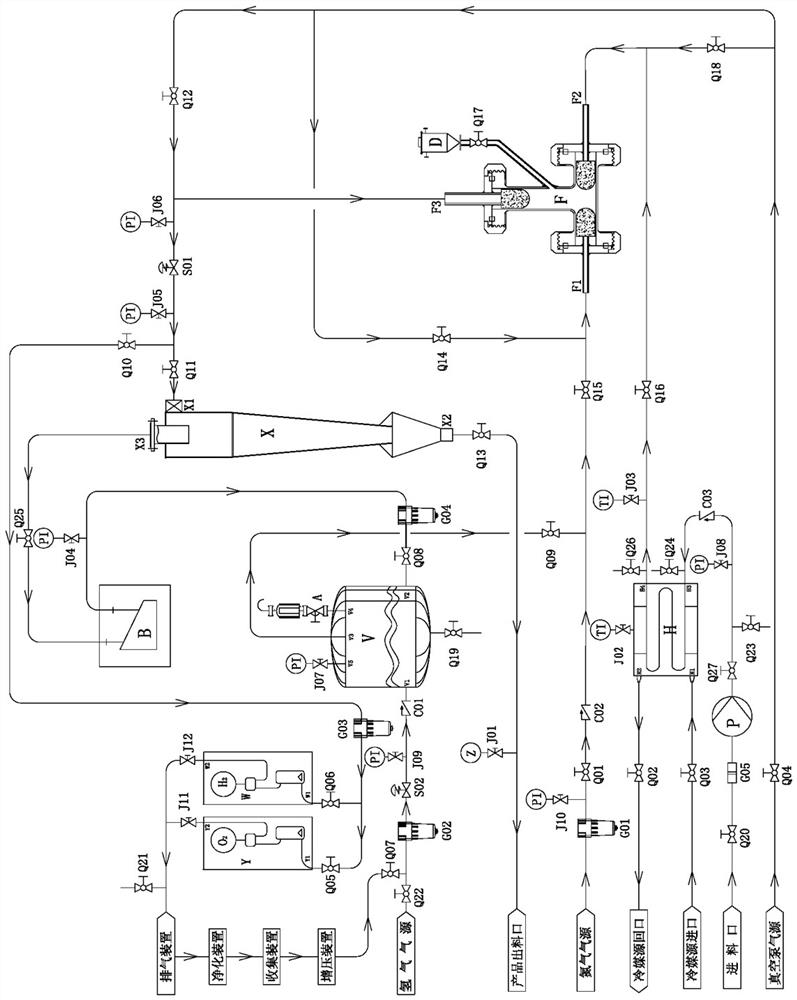

[0050] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0051] The heterogeneous reactor F described in the present invention uses the continuous mountable heterogeneous reactor mentioned in the applicant's invention patent application number 2019110912957 and new patent application number 2019219247697.

[0052] Referring to the accompanying drawings, the nitrogen gas source outlet of the present invention is connected to a feed port F1 of the multiphase reactor F through a filter G01, a ball valve Q01, a one-way valve C02 and a ball valve Q15 in sequence.

[0053] The above connections together with the multiphase reactor F and the oxygen molecule detector Y constitute a nitrogen pressure maintaining and purging circuit. When in use, close the ball valves Q09, Q11, Q12, Q14, Q18, and Q22. The nitrogen gas source is adjusted to the required pressure through the filter G01, and the gas from the multiphase re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com