Cracking furnace with double-row arranged radiant section furnace tubes

A technology for radiant furnace tubes and cracking furnaces, which is applied in the fields of hydrocarbon cracking, hydrocarbon production, organic chemistry, etc., and can solve problems affecting the radial temperature distribution of furnace tubes and bending of furnace tubes, so as to eliminate the problem of uneven heating, shorten the length, and even force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

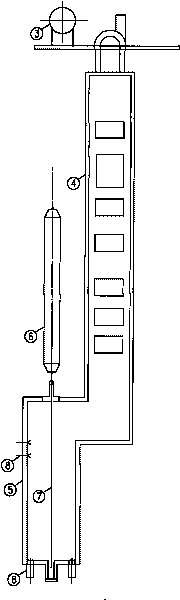

[0045] As shown in the attached picture:

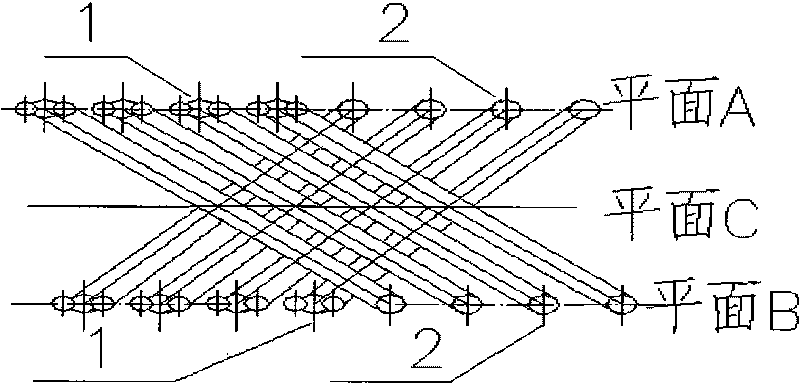

[0046] figure 2 It is a schematic top view of a group of 2-1 type furnace tube arrangement of the present invention. It consists of 8 radiation furnace tubes, in which the first pass tube 1 is arranged together, and the second pass tube 2 is arranged together; the first pass tube 1 is arranged on the left side of plane A and plane B, and the second pass The tube 2 is arranged on the right side of plane A and plane B. Plane A and plane B are symmetrical to plane C.

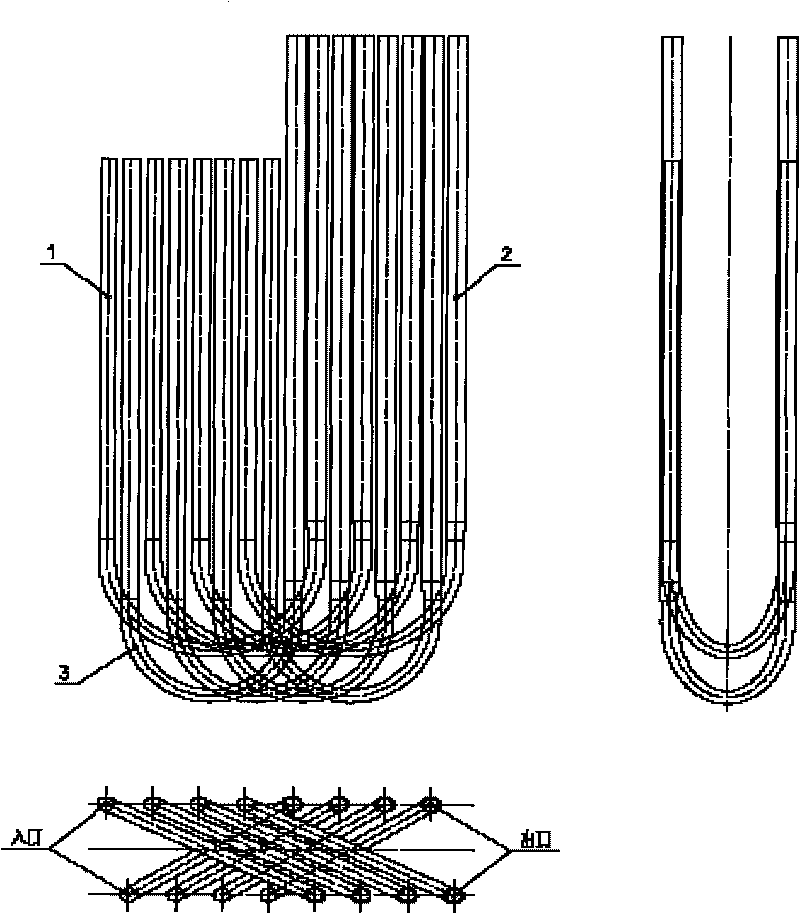

[0047] image 3 The arrangement of the furnace tubes is a group of 8 radiant furnace tubes, in which the first tube 1 is arranged on the left side of plane A and plane B, and the second tube 2 is arranged on the right side of plane A and plane B side. The connecting pipes between the first-pass pipe and the second-pass pipe are arranged in upper and lower layers. The connecting pipes of each layer are projected as a set of parallel lines when viewed from above, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com