Bridge cap anti-collision buffer bag

A buffer bag and anti-collision technology, which is applied to bridges, bridge parts, bridge construction, etc., can solve the problems of ineffective protection of ships and high costs, and achieve the effects of long service life, light weight, and easy maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

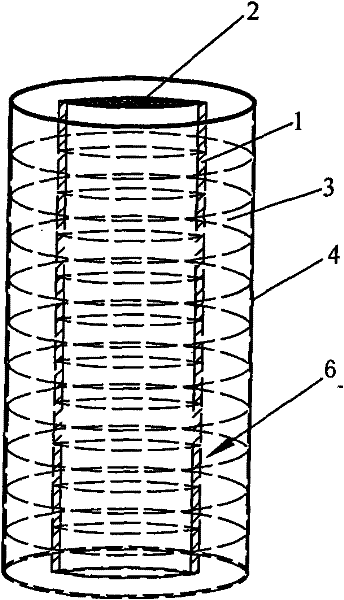

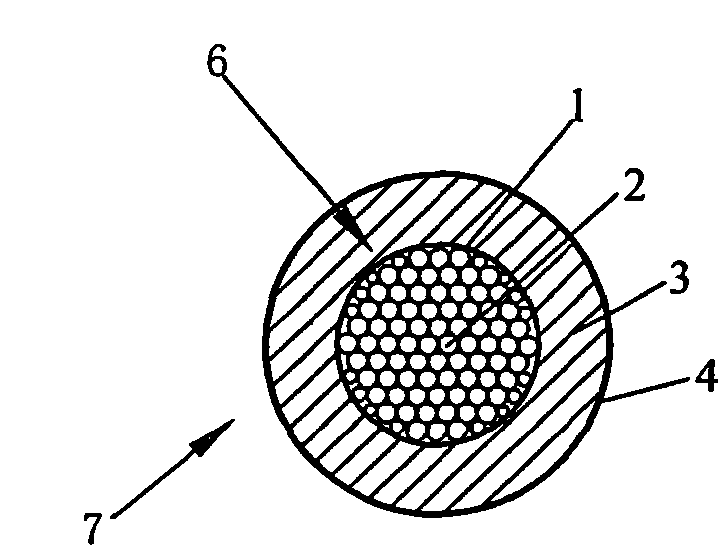

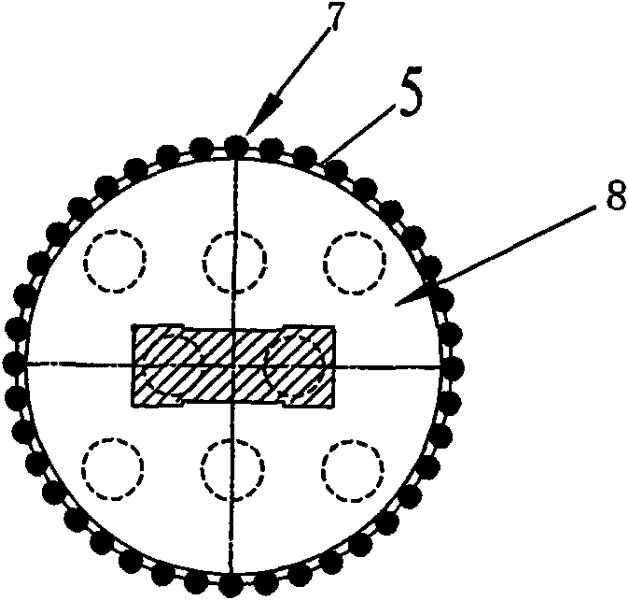

[0031] In the anti-collision buffer bag for bridge caps of the present invention, the outer diameter of the glass fiber / unsaturated polyester resin composite circular tube 1 formed by winding is 0.6m, the wall thickness is 0.02m, and the length is 5m, and the circular tube is tightly filled and vertically arranged. The moso bamboo 2 is made of composite material circular tubes as the axis, and the rubber tires are stacked sequentially. There is no filling inside the tires to form a 5m-high tire buffer column. Teflon canvas is placed on the periphery of the tire column to form a buffer bag. Fix the buffer bags at intervals around the pier caps.

example 2

[0033] In the bridge cap anti-collision buffer bag of the present invention, the outer diameter of the basalt fiber / vinyl resin composite material circular tube 1 formed by pultrusion is 0.5m, the wall thickness is 0.01m, and the length is 6m, and the polyurethane foam 2 is filled in the circular tube. Composite material round tubes are used as shafts, and rubber tires are stacked sequentially. The interior of the tires is filled with thin water bamboos bent in the circumferential direction to form a 6m-high tire buffer column. PVC canvas is placed on the periphery of the tire column to form a buffer bag. The line secures the cushion bag to the shore of the dock.

example 3

[0035] In the bridge cap anti-collision buffer bag of the present invention, the outer diameter of the carbon fiber / epoxy resin composite circular tube 1 formed by winding is 0.3m, the wall thickness is 0.005m, and the length is 3m, and the circular tube is filled with foamed aluminum 2. The round tube is used as the axis, and the rubber tires are stacked in sequence. The tires are filled with polyurethane foam to form a 3m-high tire buffer column. The PVDF canvas is placed around the tire column to form a buffer bag, and the buffer bag is fixed in the ocean with steel strands. Around the oil production platform.

[0036] The manufacture method of anti-collision buffer bag of the present invention is:

[0037] a. Prepare a set of cylindrical steel moulds. After determining the parameters such as winding angle, wall thickness, length, and diameter according to the force calculation, prepare glass fiber / vinyl resin composite material round pipe 1 by winding process on the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com