Method for producing holographic double balzed grating

A blazed grating and holographic technology, which is applied in the field of diffractive optical element preparation, can solve problems such as large surface roughness and surface shape errors, ghost lines, and difficult double blazed grating structure, and achieve the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

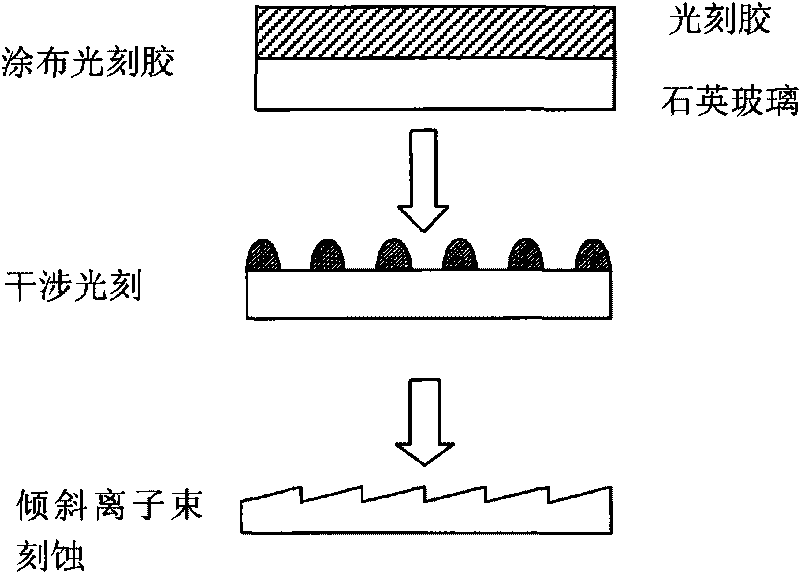

[0052] Embodiment 1: The method for making a holographic double blazed grating with a grating period of 833 nanometers and two blaze angles of 10° and 25° respectively, is realized by two interference exposures and two ion beam etching methods, including the following steps: ( Rectangular photoresist grating mask)

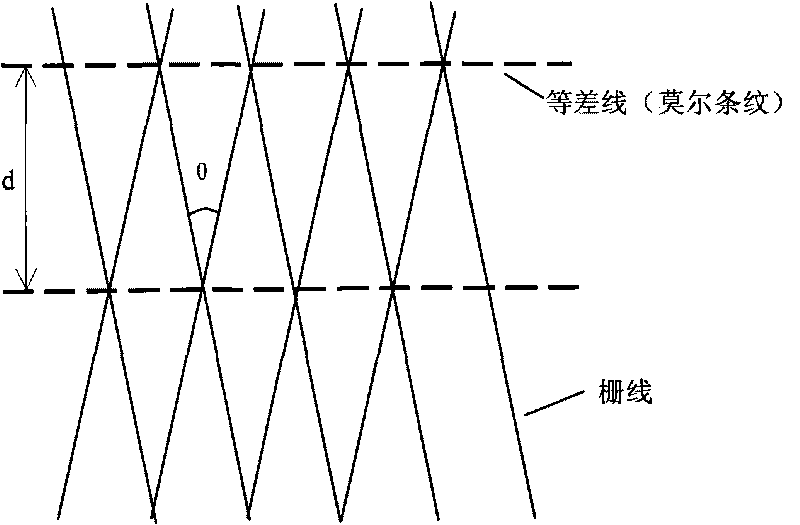

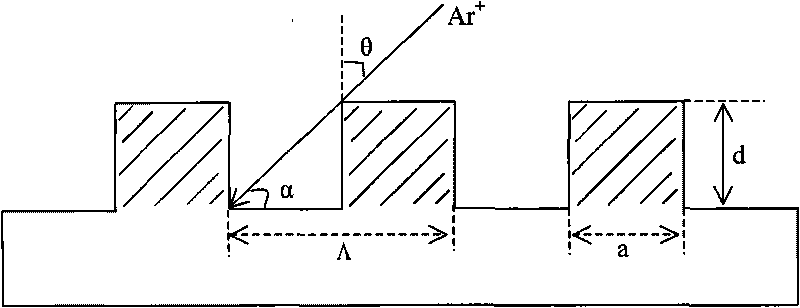

[0053] (1) Coating photoresist on the quartz substrate, according to the requirements of the double blazed grating that needs to be made, that is, the grating period (Λ) is 833 nanometers, and the two blazed angles are 10° and 25° respectively. According to the empirical formula of blaze angle θs and groove shape and ion beam incident angle, θs≈α-3°.

[0054] Using a rectangular photoresist grating (see attached image 3 ) as an example, first make a 10° blaze angle (A blaze angle) grating, generally, the duty ratio f=a / Λ=0.5, by the formula tgα = d Λ - a = ...

Embodiment 2

[0066] Embodiment 2: The method for making a holographic double blazed grating with a grating period of 1000 nanometers and two blaze angles of 10° and 25° respectively, is realized by two interference exposures and two ion beam etching methods, including the following steps: ( Triangular photoresist grating mask, see attached Figure 5 shown)

[0067] (1) Coating photoresist on the quartz substrate, according to the requirements of the double blazed grating that needs to be made, that is, the grating period (Λ) is 1000 nanometers, and the two blazed angles are 10° and 25° respectively. According to the empirical formula of blaze angle θs and groove shape and ion beam incident angle, θs≈α-3°.

[0068] Taking the triangular photoresist grating as an example, first make a 10° blaze angle (A blaze angle) grating, the general duty ratio f=a / Λ=0.5, by the formula tgα = d Λ - a ...

Embodiment 3

[0080] Embodiment 3: The method for making a holographic double blazed grating with a grating period of 1000 nanometers and two blaze angles of 12 degrees and 25 degrees respectively, is realized by two interference exposures and two ion beam etching methods, including the following steps: ( Sinusoidal photoresist grating mask, see attached Figure 6 shown)

[0081] (1) Coating photoresist on the quartz substrate, according to the requirements of the double blazed grating that needs to be made, that is, the grating period (Λ) is 1000 nanometers, and the two blazed angles are 12° and 25° respectively. According to the empirical formula of blaze angle θs and groove shape and ion beam incident angle, θs≈α-3°.

[0082] Take the sinusoidal photoresist grating as an example (the outline of the grating is as attached Figure 6 shown), first make a 12° blaze angle (A blaze angle) grating, the duty ratio of the grating is f=a / Λ=0.5, and the profile of the grating can be expressed by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com