Preparation method of high dispersibility superfine silver powder with adjustable grain diameter

A high-dispersion, ultra-fine silver technology, applied in the field of liquid-phase preparation of ultra-fine silver powder, can solve the problems of difficult control of powder dispersion, unfavorable mass industrial production, low output per unit volume, etc., to achieve densification and shrinkage The effect of low yield, excellent end product performance and narrow particle size distribution

Active Publication Date: 2010-06-16

GUANGDONG FENGHUA ADVANCED TECH HLDG

View PDF2 Cites 55 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The technical point of preparing silver powder by liquid phase reduction method is to control the dispersion, size and uniformity of the reduced silver particles, because the ultrafine powder is easy to agglomerate in the aqueous solution, resulting in poor dispersion, which is difficult to meet the requirements of ordinary electronic paste, especially It is the printing and sintering demand of high-end silver paste. For example, the patent with application number 200510128715.6 requires subsequent heat treatment, and the concentration of reactants is low, and the output per unit volume is low, which is not conducive to mass industrial production. Although the patent with application number 200710049490.4 is silver nitrate The concentration is high, but it does not involve the selection of surfactants, and the dispersibility of the powder obtained by reduction is difficult to control

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Login to View More

Abstract

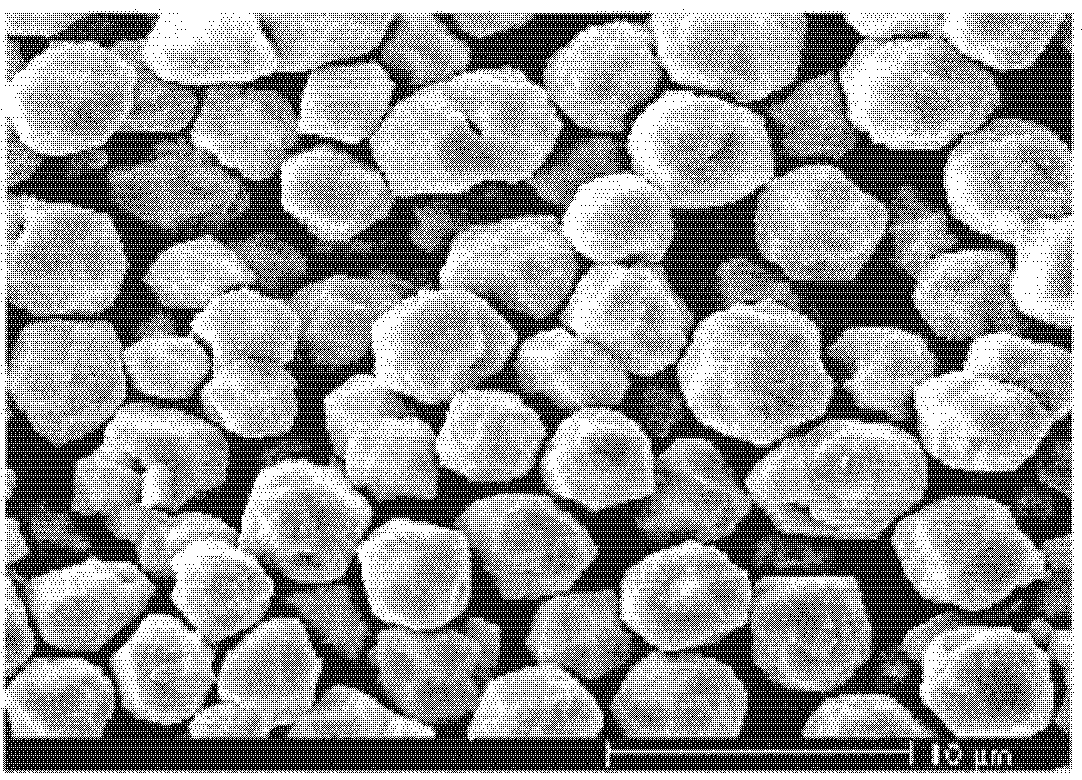

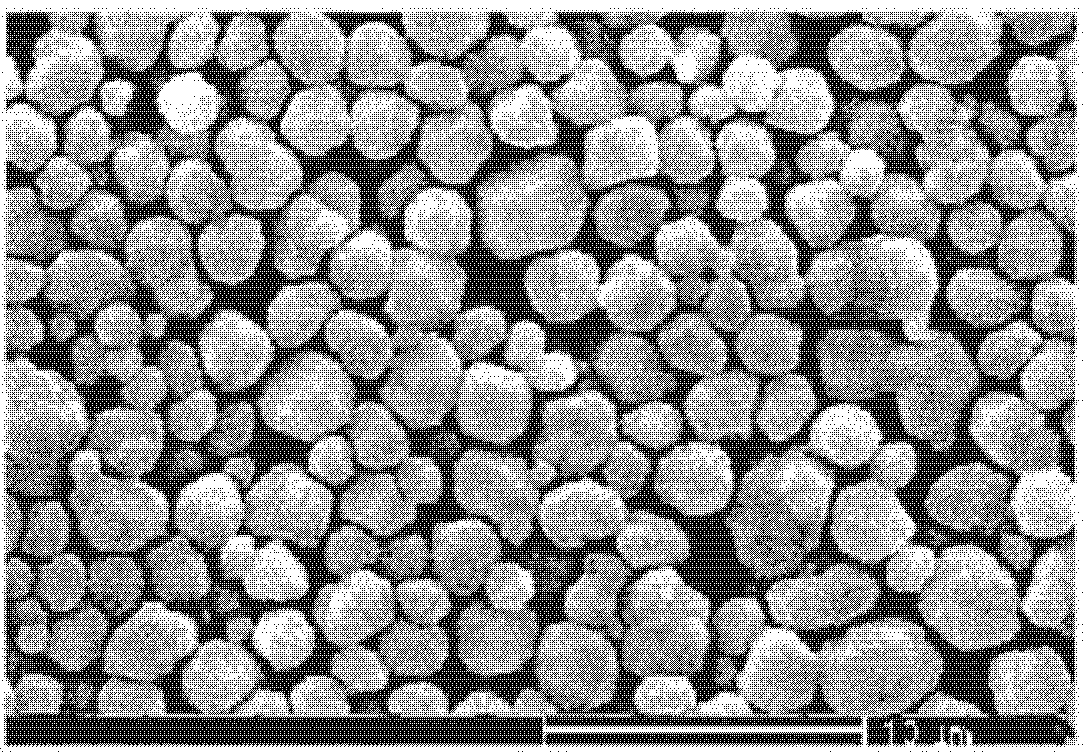

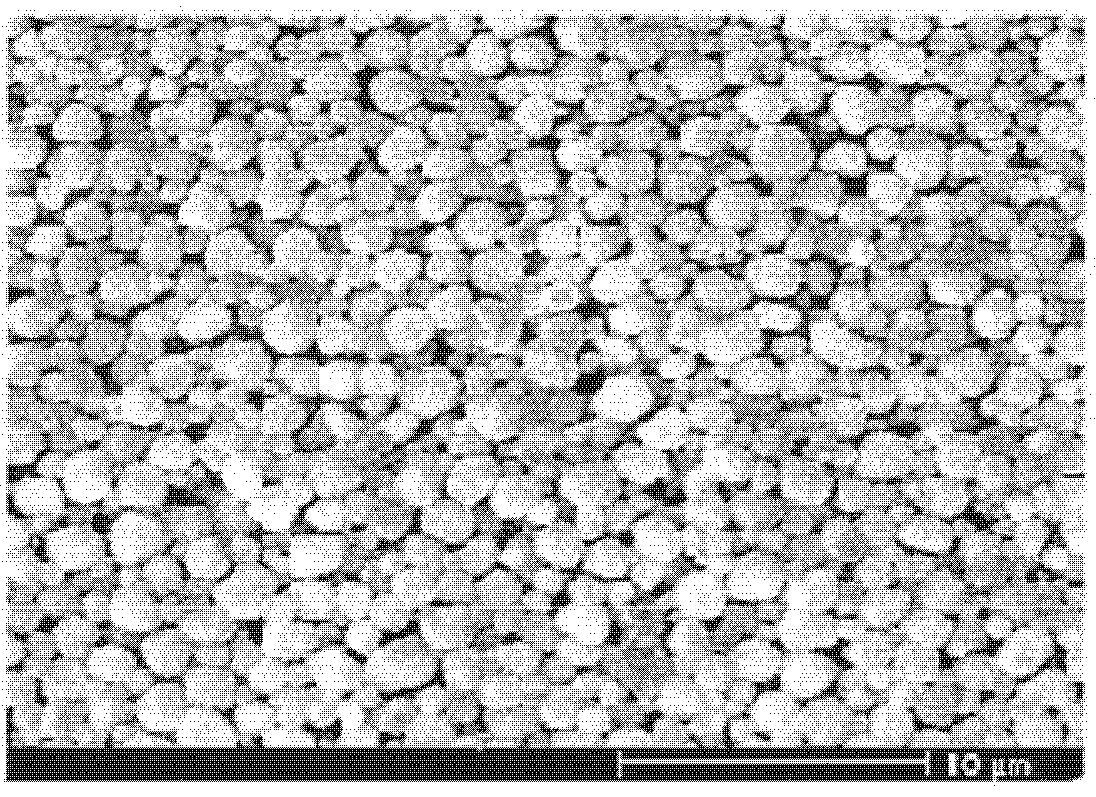

The invention relates to a preparation method of high dispersibility superfine silver powder with adjustable grain diameter, comprising the following steps: 1. dissolving silver nitrate and surfactant in water to prepare silver solution A; 2. dissolving ascorbic acid, PH regulator and surfactant in water to prepare reducing liquid B; 3. preparing alkaline aqueous solution C by alkaline PH regulator; dropwise adding alkaline aqueous solution C and silver solution A to reducing liquid B at the set time. PH value of the reducing liquid B and flow velocity of alkaline aqueous solution C are adjusted, so that silver power particle size can be easily adjusted and the silver power particles can grow up uniformly. The silver powder obtained by the method of the invention has the characteristics of polyhedral microcosmic appearance, good dispersibility, narrow size distribution, high tap density and good sintering character.

Description

technical field The invention relates to a liquid-phase preparation method of ultrafine silver powder, in particular to a preparation method of highly dispersed ultrafine silver powder with adjustable particle size used in electronic paste. Background technique Silver powder is the most widely used and the largest amount of precious metal powder in the electronics industry. Its morphology, particle size, uniformity, and dispersion are key factors affecting the film-forming performance of silver paste. Therefore, it can be used to make various low-temperature Curing polymer silver paste, conductive adhesive, or sintered silver paste including electrode paste for various ceramic components. The most commonly used method for preparing silver powder in large quantities at present belongs to the liquid phase reduction method. The production process and equipment of the liquid phase reduction method are simple, the production cost is low, and the product performance is controllab...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B22F9/24

Inventor 孟淑媛唐元勋吴海斌彭建雄孔祥冬陆进辉黄相文

Owner GUANGDONG FENGHUA ADVANCED TECH HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com