Method and device for manufacturing pure white spirit

A kind of white wine, pure technology, applied in the field of white wine production, can solve the problems of difficult operation, incomplete removal of rich impurities, etc., to achieve the effect of convenient operation, easy automatic control, pure and sweet taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

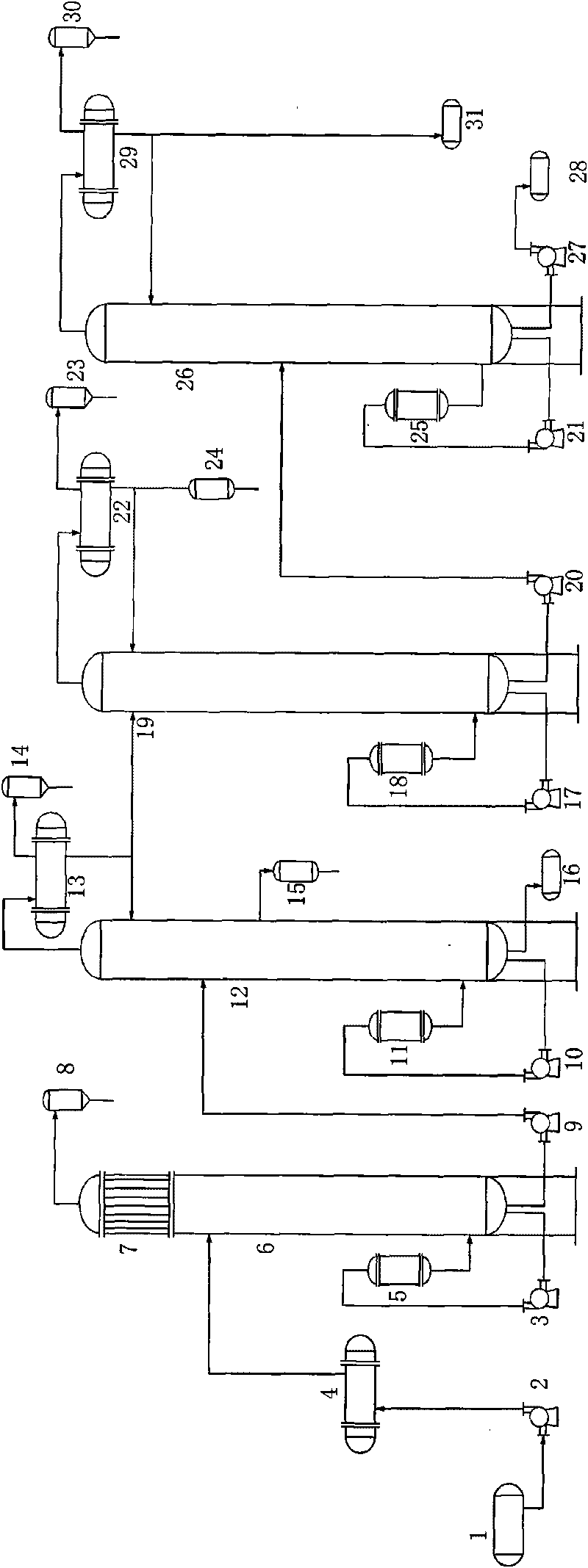

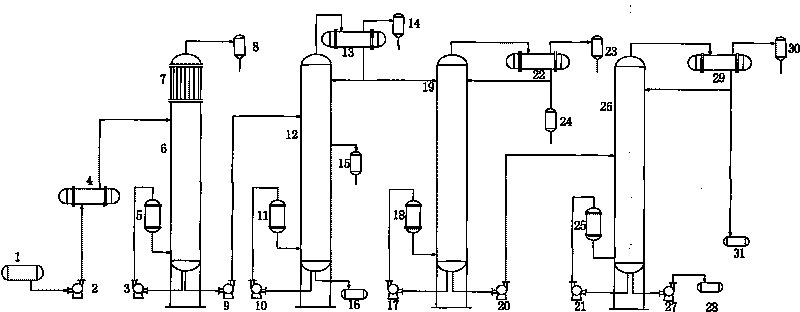

Embodiment 1

[0052] Four high-vacuum low-temperature rectification towers are adopted, the tower diameters are 150mm, 100mm, 80mm, and 80mm respectively. The tower equipment and the matching falling film short-range reboiler are all manufactured by Shanghai Research Institute of Chemical Industry. The special packing in the rectification tower And the tower internals are all developed by the National High Efficiency Separation Tower Packing and Device Technology Research and Promotion Center. process such as figure 1 shown. The wine used in the test is a traditional 56-degree liquor of a certain domestic brand, and the ethanol concentration in the original wine is 56% (V / V). The raw wine is sent to the de-alcoholization tower 6 by the pump 2 at a flow rate of 5 L / h, and the de-alcoholization tower top is provided with a de-condenser 7, which is a secondary condenser. After passing through the secondary condenser, the top temperature of the dealdehyde tower is controlled at 5° C., the top...

Embodiment 2

[0063] A device for producing pure liquor and vodka using traditional liquor, the device includes the original wine tank, preheater, dealdehyde tower, alcohol tower, alcohol tower, methanol tower, condenser, reboiler, cold trap tank, spice tank, Wine tank, methanol tank and alcohol tank, the original wine tank is connected to the preheater pipe, the preheater is connected to the middle and upper part of the dealdehyde tower, the top of the dealdehyde tower is connected to the cold trap tank, the tower kettle is equipped with a reboiler, and the dealdehyde The tower kettle is connected with the middle pipeline of the dealcoholization tower, the top of the dealcoholization tower is equipped with a condenser, the side of the condenser is connected to the cold trap tank, the middle part of the dealcoholization tower is equipped with a spice tank, and the tower kettle is equipped with a reboiler and wine liquid Tank, the upper part of the alcohol tower is connected to the pipeline o...

Embodiment 3

[0071] A device for producing pure liquor and vodka using traditional liquor, the device includes the original wine tank, preheater, dealdehyde tower, alcohol tower, alcohol tower, methanol tower, condenser, reboiler, cold trap tank, spice tank, Wine tank, methanol tank and alcohol tank, the original wine tank is connected to the preheater pipe, the preheater is connected to the middle and upper part of the dealdehyde tower, the top of the dealdehyde tower is connected to the cold trap tank, the tower kettle is equipped with a reboiler, and the dealdehyde The tower kettle is connected with the central pipe of the dealcoholization tower, the top of the dealcoholization tower is equipped with a condenser, the side of the condenser is connected to the cold trap tank, the middle part of the dealcoholization tower is equipped with a spice tank, and the tower kettle is equipped with a reboiler and wine liquid Tank, the upper part of the alcohol tower is connected to the pipeline on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com