Floating-type wave energy utilization device with strong fault tolerance and high efficiency

A wave energy, floating technology, applied in the direction of ocean energy power generation, engine components, machines/engines, etc., can solve the problems of large impact load, large size, complex machinery and power generation mechanism, etc., to achieve strong buffering capacity and strong buffering. Ability, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment content of the present invention is described in further detail:

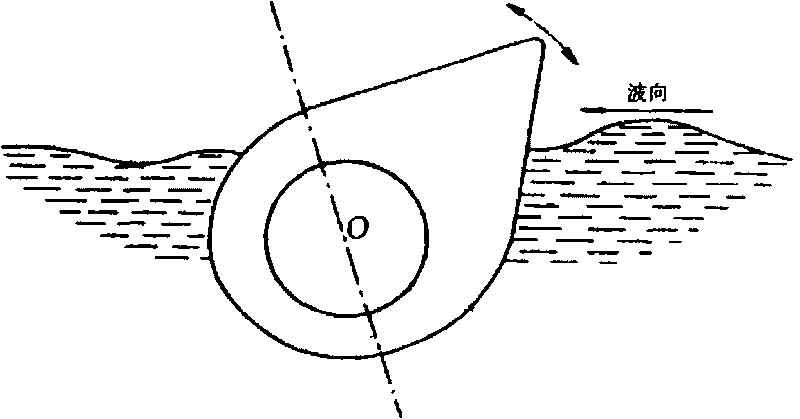

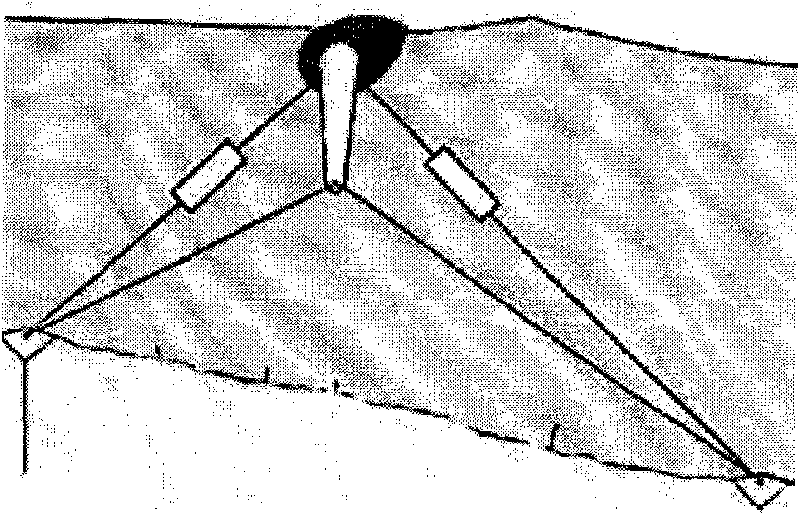

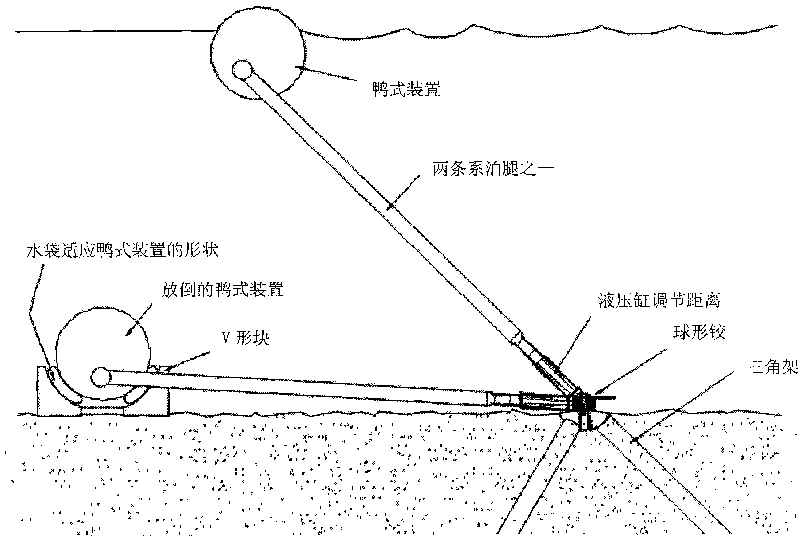

[0023] Such as Figure 4 As shown, the device of this embodiment includes a duck body 2 floating on the water surface. The duck body is composed of a head and a tail. 1 turn. The part of the central axis inside the duck body shell is a circular section, and the shaft end exposed outside the duck body shell is cylindrical, and the diameter is larger than the central axis installation hole of the duck body shell; the tail of the duck body is arc-shaped; Body head back wave position increases volume; Underwater appendage 7 fixedly connected with central axis is installed under duck body 2, and underwater appendage 7 is made up of larger horizontal plate and vertical plate. The underwater appendage 7 is hung on the shaft end of the central shaft 1, and hangs under the duck body 2. The central shaft 1 is fixed by the underwater appendage 7; The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com