Mobile crane, steering mid positioning and locking device and mid cylinder thereof

A locking device and oil cylinder technology, which is applied in fluid pressure actuating devices, fluid steering mechanisms, running gears, etc., can solve the problems of inability to realize automatic neutral control of steering axles, complex structure of steering locking devices, and inability to realize instantaneous automatic locking, etc. Problems, to achieve the effect of convenient wire steering and rodless steering design and layout, light weight and reliable hydraulic locking function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

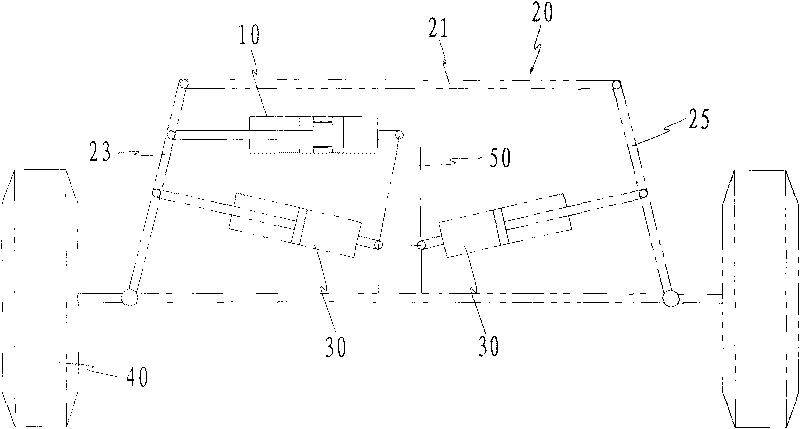

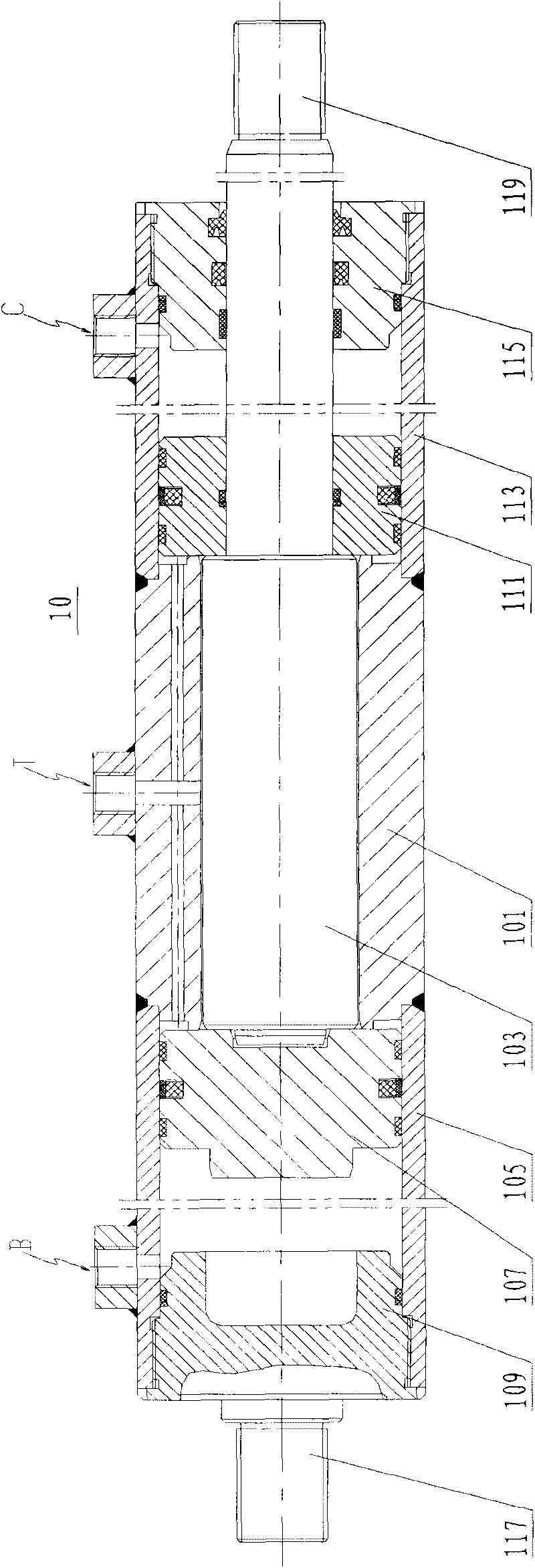

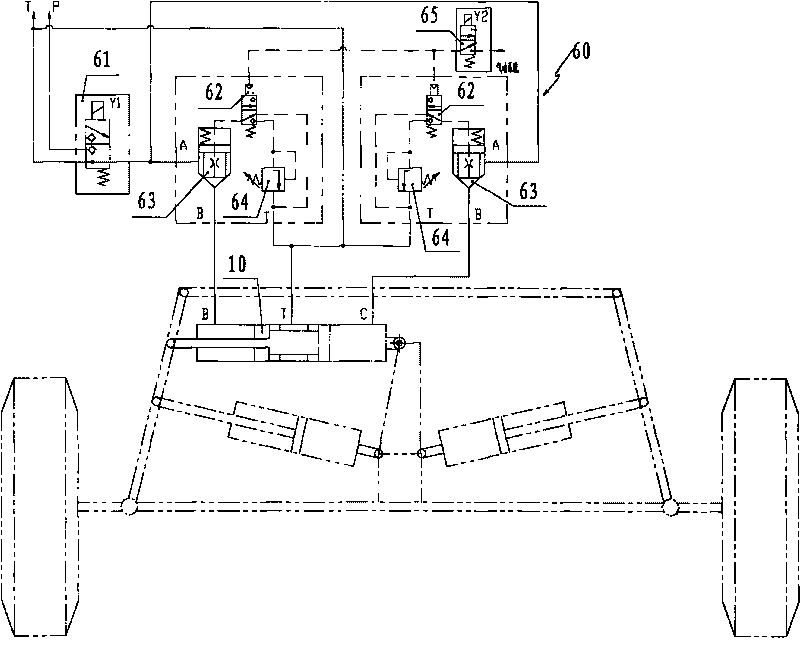

[0029] figure 1 A schematic diagram showing the installation of the middle oil cylinder on the steering axle according to the present invention is shown. As shown in Figure 1, the steering tie rod 21 and the trapezoidal arms 23, 25 form a steering trapezoid, the middle oil cylinder 10 is installed between the axle 50 and the trapezoidal arm 23, and there is also a set between the trapezoidal arms 23, 25 and the axle 50. Turn to resistance oil cylinder 30.

[0030] By setting the middle position oil cylinder 10, the steering axle can be rigidly locked in the middle position for straight driving, ensuring the high-speed running stability of the vehicle; when it is free to disengage, it is convenient for the steering axle to turn freely, realizing a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com