Ruthenium-nickel composite electrode and preparation method thereof, and application of ruthenium-nickel composite electrode

A composite electrode and electrode technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor low-temperature electrochemical performance, poor ammonia catalytic activity, etc., and achieve good load stability, improved reaction interface, and good low-temperature activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a method for preparing a ruthenium-nickel composite electrode, comprising:

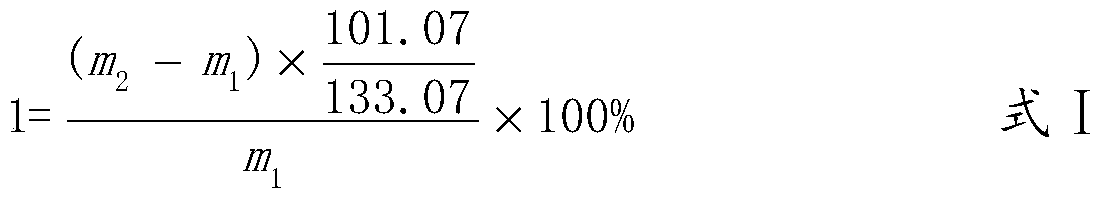

[0039] The nickel base electrode body (mass is m m) used in this embodiment 1 ) includes a first material and a second material, the first material is YSZ, the second material is nickel oxide, the mass ratio of the first material and the second material is 4:6; the content of ruthenium in the ruthenium-nickel composite electrode is 1wt%;

[0040] Preparation methods include,

[0041] (1) Weigh 0.3g of 5wt% ruthenium nitrate solution, add 0.3g of absolute ethanol and slightly shake it up as the precursor solution of ruthenium for later use, then drop-coat the precursor solution of ruthenium onto the body of the nickel-based electrode, and let it stand for 1h , and then dried at 100°C for 1 hour;

[0042] (2) Heat up to 450°C at a heating rate of 1.2°C / min for calcination, and then cool down to room temperature after 20 minutes of calcination to obtain a ruthenium oxide...

Embodiment 2

[0049] This embodiment provides a method for preparing a ruthenium-nickel composite electrode, comprising:

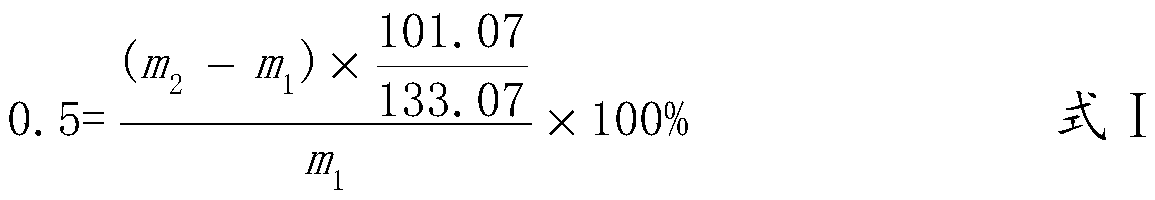

[0050] The nickel base electrode body (mass is m m) used in this embodiment 1) includes a first material and a second material, the first material is BCZY, the second material is nickel oxide, the mass ratio of the first material and the second material is 7:13; the content of ruthenium in the ruthenium-nickel composite electrode is 0.5wt% ;

[0051] Preparation methods include,

[0052] (1) Weigh 0.05g of ruthenium chloride, add 0.4g of deionized water and slightly shake it up as the precursor solution of ruthenium for later use, then drip-coat the precursor solution of ruthenium onto the nickel-based electrode body, let it stand for 1.2h, and then Dry at 120°C for 0.4h;

[0053] (2) Heat up to 500°C at a heating rate of 1.0°C / min for calcination, and then cool down to room temperature after 15 minutes of calcination to obtain a ruthenium oxide nickel-based composit...

Embodiment 3

[0060] This embodiment provides a method for preparing a ruthenium-nickel composite electrode, comprising:

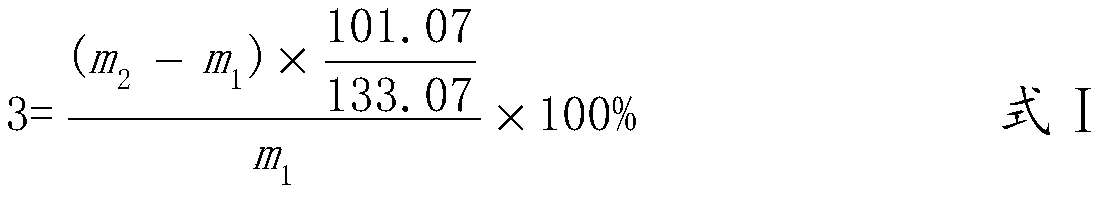

[0061] The nickel base electrode body (mass is m m) used in this embodiment 1 ) includes a first material and a second material, the first material is GDC, the second material is nickel oxide, the mass ratio of the first material and the second material is 9:11; the content of ruthenium in the ruthenium-nickel composite electrode is 3wt%;

[0062] Preparation methods include,

[0063] (1) Weigh 0.5g of ruthenium nitrate with a mass fraction of 5wt%, add 0.3g of absolute ethanol and shake it up slightly, then use it as the precursor solution of ruthenium for later use, then drop-coat the precursor solution of ruthenium onto the nickel-based electrode body, statically Set for 0.5h, then dry at 80°C for 1.2h;

[0064] (2) Heat up to 500°C at a heating rate of 1.5°C / min for calcination, and then cool down to room temperature after 20 minutes of calcination to obtain a rut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com